1 Analysis of the current situation and problems of the filter press system in coal processing plant

1.1 The content of fine particle size in coal slurry increases. The coal processing plant of Xiegou Mine adopts the combined process of 150-50mm lump coal heavy-medium shallow chute, 50-1.5mm heavy-medium cyclone main re-election, and 1.5-0.2mm coarse coal slurry TCS sorting, and the remaining fine-grained coal slurry is dewatered and recovered by the sedimentation and filtration centrifuge and the fast-opening diaphragm filter press. Through the continuous exploration and implementation of coal slurry reduction technology in recent years, including measures such as reducing the screen slit of the final raw coal desliming screen, reducing the screen slit of the TCS concentrate dewatering arc screen and coal slurry centrifuge, increasing the inner diameter of the bottom flow opening of the TCS feeding cyclone group, and decreasing the flow rate of water on the top of the TCS separator, etc., the effect of intercepting the coarseness has been obvious. Most of the coal slurry with particle size larger than 0.074mm has been effectively recovered in TCS sorting and sedimentation dewatering, which reduces the load of the high-efficiency thickener. The yield of filter press slurry also decreased from 8.0% to 6.5%~7.0%, and the proportion of less than 0.074mm particle size class in the filter feed of this plant reached about 80%, with large specific surface area, developed pore structure, strong water absorption, and large viscosity of suspension liquid, which made dewatering quite difficult. The dewatering efficiency of the fast-opening filter press decreases significantly when dealing with ultra-fine-grained coal slurry, the filter press cycle becomes longer, the moisture of the filter cake is as high as 25%~27%, and it is easy to adhere to the filter plate, and it is easy to cause safety accidents by manually poking down the filter cake.

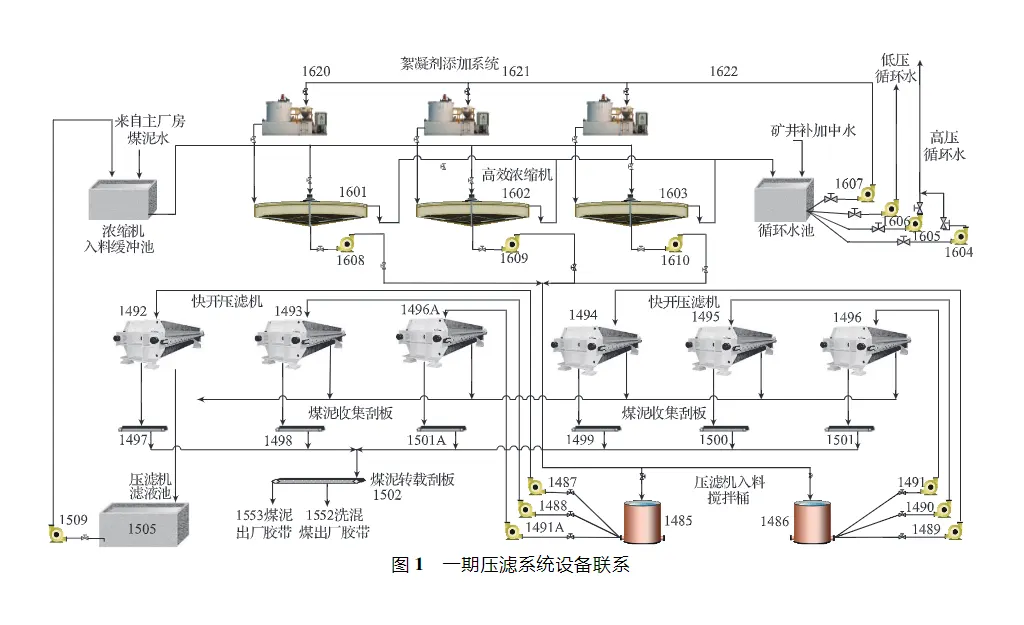

1.2 The proportion of coal slurry blended into washed coal is restricted There are 12 sets of quick-opening filter presses in the plant, including 6 sets each in the first-phase and second-phase filter presses, which are arranged in a mirror image, and the connection of the equipment of the first-phase filter press system is shown in Figure 1.

In the production process, through the 1502 coal slurry reproduction scraper can be directly mixed into the washed coal, as a power coal sales; also can enter the 1553 coal slurry factory tape machine landing, in situ drying and then by the automobile ground sales. As the contract index of washed coal moisture is less than 10.0%, the moisture level of filtered coal slurry directly affects the proportion of washed coal blended into it. In order to avoid the loading of the car bin and winter freezing accidents, the plant can only strictly control the amount of coal slurry into the mix, especially when the two-phase system at the same time wash fine coal, often half of the mixing half of the landing. The filtered coal slurry after landing can only be disposed of locally according to the tailing coal at a lower price, resulting in a significant reduction in the economic benefits of the enterprise, and environmental pollution caused by a series of links such as coal slurry stockpiling, loading and transporting.

1.3 Aging of the original filter press The original filter press was put into use in 2010, with different degrees of aging of the electric control and hydraulic systems, deformation of the frame, frequent failures and high maintenance costs. In view of the above problems, the plant urgently needs to find a new type of filter press to replace the original fast-opening filter press to further reduce the moisture of coal slurry, so as to realise that the filtered coal slurry can be fully incorporated into the blended coal, improve the quality of coal slurry, and increase the economic benefits.

2Through-flow filter pressesEquipment CharacteristicsThrough-flow filter press is called "single chamber feeding air through flow water washing cake filter press", which is a new type of filter press and dewatering equipment developed on the basis of fast-opening filter press in recent years, and has a good effect on the dewatering of fine grain coal slurry.In 2019, the Group's Dongqu and Malan Coal Processing Plants have completed the reconstruction of through-flow filter press successively, and the moisture of filter cake has been greatly reduced to achieve the expected effect. , the moisture of the filter cake was substantially reduced and the expected effect was achieved.

2.1 The working principle of the equipment filter slurry in the feed pump, driven by the main feed pipe to each chamber of the separate diversion of feed, solid particles in the filter cloth to form a cake, the filtrate through the filter cloth from the filtrate discharge port centralised discharge. Different from the quick-opening filter press plate, through-flow filter press has a unique angle blowing function, through the compressed air penetrates the filter cake to bring out the liquid water with the air, effectively reducing the moisture of the filter cake; through the diaphragm filter plate membrane function, the high pressure water is injected into the diaphragm filter plate by the pressing pipeline to change the volume of the filter chamber through the water pressure to press the filter cake, and further reduce the moisture of the filter cake. The whole action process of through-flow filter press is as follows: pressing→feeding→backblowing→water pressing→cake air-drying→second backblowing→unloading. High-pressure water membrane pressing, cake air-drying and product moisture is directly related to these two links is also a single chamber feeding air through the flow of water washing filter cake filter press features.

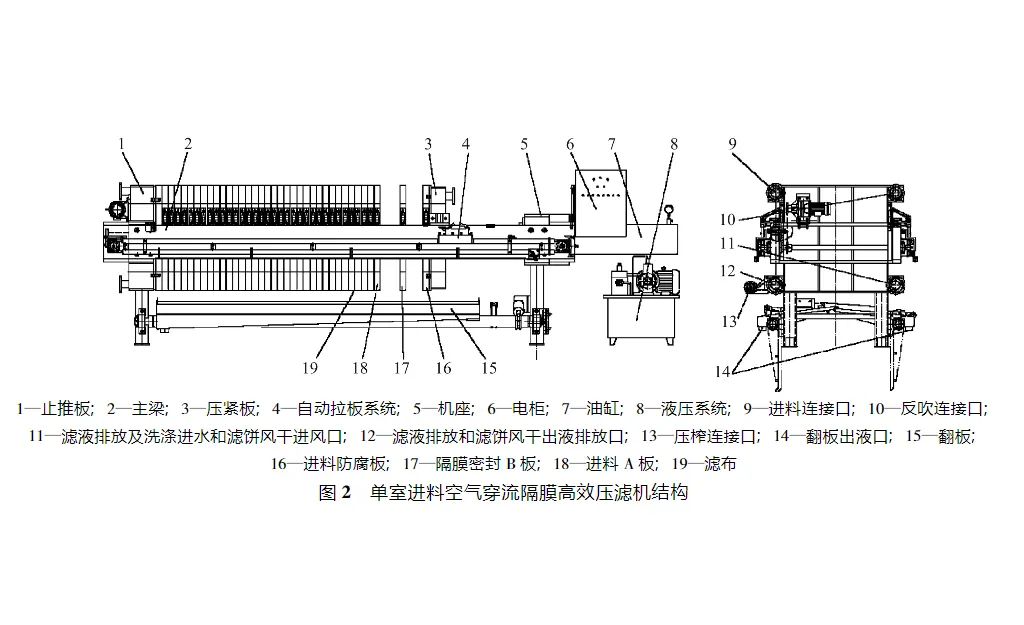

2.2 Equipment structure The structure of the single-chamber feed air-through-flow diaphragm high-efficiency filter press is shown in Figure 2.

Filter plate configuration is the core component of through-flow filter press, each chamber consists of feed A plate and sealing B plate combined into an independent confined space, the diaphragm sealing B plate is the water intake and air intake plate for washing and cake air-drying, and the feed A plate is the drainage and exhaust plate for washing and cake air-drying. Compared with the feeding at the two ends of the centre of the quick-opening filter press, the filtering area is increased by about 6% to 10%, which effectively ensures the uniformity of the thickness of the filter cake. The air-drying function of the filter cake helps to separate the filter cake from the filter cloth when discharging, and the filter cake falls off automatically, which reduces the hidden safety risks.

3 through the flow of filter press semi-industrial test in order to verify the effect of filtration of coal slurry precipitation, the plant used through the flow of filter press test machine on-site semi-industrial test, and the original fast-opening filter press for dewatering of the thickener underflow effect comparison. In order to ensure that the nature of the feed of the two models is the same, each group of tests were selected at the same point in time. The moisture of through-flow filter press was obviously reduced, the highest 20.0%, the lowest 18.2%, and the average was 19.3%, and the cake moisture was reduced by 7.0% compared with that of the existing quick-opening filter press, which showed a significant effect of water reduction, indicating that the through-flow filter press had a strong adaptability to the concentration and nature of the materials in the plant, and the cake moisture showed a decreasing trend with the rise of the water pressing pressure. The trend of the filter cake moisture is decreasing with the increase of water pressing pressure.

4 technical transformation programme design for the existing equipment layout and plant space conditions in the coal processing plant in Xiaogou Coal Mine, the original 12 sets of fast-opening filter presses one-to-one replacement of 12 sets of the same manufacturer through the flow of filter presses, a single filtration area of not less than 560m2, the foot of the size of the length / width of 10630mm × 1690mm, and the same position as the foot of the original equipment. The feeding pump of the original filter press can meet the feeding requirements of the new through-flow filter press and does not need to be replaced. It is necessary to purchase the press water tank and press pipeline pump which are matched with the filter press one by one, the volume of the water tank is 38m3, adopting multi-stage pump, flow rate is 65m3/h, and the head is 140~160 m. The number of air compressors is determined: the air volume of a single circulating penetrating filter press is 40~50m3/min, in order to ensure that the coal slurry is uniformly fed into the washed and blended coal, the single-phase system only allows two filter presses to unload the material at the same time, and the angle blowing and reverse blowing of the filter presses is not suitable for the new filter press, so the filter presses have to be installed at the same time. In order to ensure the homogeneity of coal slurry into the washing mix, the single-phase system only allows two filter presses to unload the material at the same time, and each filter press angle blowing and blowing process can be staggered through the intelligent control programme, two filter presses simultaneously into the cake air-drying and blowing link requires a stable pressure of compressed air of about 100m3/min, so three sets of air compressors with an exhaust volume of 40m3/min and an exhaust pressure of 1.0MPa for air supply may satisfy the daily production demand of the single-phase system. Determination of the number of storage tanks: According to the recommended storage tanks for filter presses, the air compressors for filter cake drying and blowback are relatively independent, and the blowback air can be satisfied by using the original system storage tanks. In addition, each phase of the system is equipped with 3 sets of 40m3 storage tanks to supply air for the filter cake air-drying process of the filter press.

5.2 Social benefits of filtering coal slurry into the mixing of washing and blending coal after all through the train sales, put an end to the coal slurry landing drying ground sales, to avoid the environmental pollution caused by the coal slurry stockpiling, transport and the problem of environmental pollution.

6 Conclusion Through-flow filter press transformation programme is technically feasible, economically reasonable, and can be implemented without affecting the normal production of the coal preparation plant, which not only increases the economic benefits of the enterprise, but also protects the ecological environment of the mining area. Wear-flow filter press is an advanced fine-grained coal dewatering equipment in China, adopting advanced air-drying and high-pressure water pressing technology, the water content of fine-grained coal filter cake is much lower than other dewatering equipment, solving the "difficult" problem of coal slurry disposal in coal processing industry, and it is a technological revolution of fine-grained coal filter press dewatering.

Disclaimer: The copyright of this article belongs to the original author and the original source.

Welcome to call us for consultation, technical exchange, and material experiment.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses