Nonwoven Filter Cloth

Non-woven filter clothIs polyester, polypropylene raw materials manufacturing, through the needle punching, combing, cloth centre plus woven cloth sandwich, and then through the double channel nucleation, airflow into the net needle punching composite into cloth after the pressure filter cloth has a three-dimensional structure, after heat-setting, sintering, in the surface of the chemical oil treatment, so that the appearance of the filter cloth smooth, uniform distribution of microporous, from the surface of the product's density is good, the surface of the two surfaces is smooth and good degree of permeability, filtration in plate and frame compressor to prove the use of The product can be used with high pressure and the filtration precision is up to 4 microns, and the product can be supplied with two kinds of raw materials of polypropylene and polyester according to the needs of users.

Advantages of non-woven filter cloth

1. Lightweight: polypropylene resin as the main raw material, specific gravity is only 0.9, only three-fifths of cotton, with fluffy, feel good.

2. Softness: made up of fine fibres (2-3D) lightly dotted with hot melt bonding. The finished product is moderately soft and comfortable.

3. Water-repellent, breathable: polypropylene slices do not absorb water, water content of zero, the finished water-repellent good, composed of 100% fibres with porous, breathable, easy to keep the cloth dry, easy to wash.

4. Non-toxic, non-irritating: the product is produced with FDA food-grade raw materials, does not contain other chemical components, stable performance, non-toxic, no odour, does not irritate the skin.

5. Antibacterial, anti-chemical agents: polypropylene is a chemical passive substance, not insect, and can isolate the presence of bacteria and insects within the liquid erosion; antibacterial, alkali corrosion, finished products do not affect the strength of erosion.

6. Antibacterial. Products with water pulling, not mouldy, and can isolate the existence of liquid bacteria and insects within the erosion, not mouldy.

7. Good physical properties. Spun by the polypropylene directly laid into a network of thermal bonding, product strength is better than the general short-fibre products, the strength of non-directional, longitudinal and transverse strength is similar.

Industrial filter cloth performance indicators

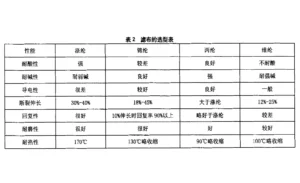

| Performance | polyester | nylon | polypropylene fiber | (loanword) vinylon, synthetic fiber made from polyvinyl alcohol |

| Acid resistance | vigorous | mediocre | favourable | acid-intolerant |

| Alkali resistance | alkali-resistant | favourable | vigorous | alkali |

| Electrical conductivity | poorly | preferably | favourable | usual |

| elongation at break | 30%-40% | 18%-45% | Larger than polyester | 12%-25% |

| Resilience | an excellent | At 10%, above 90% | Slightly better than spandex | mediocre |

| Abrasion resistance | an excellent | an excellent | (of an unmarried couple) be close | preferably |

| Heat Resistance | 170 °C | 130 °C Slight shrinkage | 90 °C slight shrinkage | 100 °C Shrinkage |

| Softening point | 230 °C -240 °C | 180 °C | 140 °C -150 °C | 200 °C |

| Melting Point | 255 °C -265 °C | 210 °C -215 °C | 165 °C -170 °C | 220 °C |

Coal Processing Plant Nonwoven Filter Cloth Application

nonwovenfilter clothGood performance in plate and frame filter press: For example, in the coal sludge treatment of coal processing plant, if using other specifications of filter cloth (except specially treated EP3927, ET120-7, ET8222 filter cloth PP750A filter cloth), there will be the problem that the cake is not dry and difficult to fall off, after using non-woven filter cloth, the cake will be quite dry when the pressure of the filter machine reaches 10kg-12kg, and the cake will automatically fall off when the filter machine opens the frame. The cake will fall off automatically when the filter is opened.

It is used in plate and frame filter press of dyestuff factory, and in plate and frame filter press of iron and steel factory for waste water treatment; and in plate and frame filter press of brewery and printing and dyeing factory for waste water treatment, it has the same excellent performance, especially when the plate and frame filter press needs to be clamped on the filter paper, this kind of cloth can be used only for one-time use because of its inner fibre layer similar to the fibre layer of the filter paper and the filter paper is made of wood pulp and paper pulp which can not be washed, and it can be used together with the chemical fibre when it has not been treated on the surface. Non-woven filter cloth without surface treatment can be used with chemical fibre filter paper (cloth) composite, filtration accuracy can reach 1 micron. After surface treatment to be used alone, the performance is very good, easy to wash after use, can be reused after washing, the economic use of better value.

Contact Us

Sales:181-181-000-11

Selection:188-517-18-517

Mailbox:suton@su-ton.com

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses