1 Overview

filter pressAs a mature dewatering equipment, it is widely used in the field of environmental protection, becoming an important equipment for sewage sludge treatment, mainly used for solid-liquid separation of all kinds of sludge sludge, which can be applied to solid-liquid separation of water treatment process in various industries, sludge drying treatment process, greatly improving the efficiency of sewage treatment and reducing the discharge of waste.filter pressRoughly can be divided into chamber filter press, belt filter press and plate and frame filter press. Yixing China Resources Thermal Power Co., Ltd. 2 × 60MW unit was put into operation, the company's wastewater treatment process using coagulation and precipitation of sludge after drying treatment, the main source of sludge for the desulfurization system and ash system, sludge drying equipment using manually reinforced polypropylene chamber filter presses, the daily amount of drying sludge for 12 tonnes, the sludge filtering process of the normal operation of wastewater treatment system plays a decisive role. 2 chamber filter presses The working principle of chamber filter press is a solid-liquid separation equipment integrating machine, electricity and liquid, mainly composed of frame, filtering part, hydraulic part and electric part.

The frame is the basic part of the filter press, the two ends are the thrust plate and the pressing head, both sides of the beam will be connected to the two, the beam is used to support the filter plate, the filter frame and the pressing plate: the hydraulic part of the pressing mechanism consists of a hydraulic station, cylinder, piston, piston rod and piston rod and the pressing plate connection; the filtration part consists of the filter plate, the filter frame, the filter cloth, the press diaphragm, the two sides of the plate by the filter cloth cover; the electrical part consists of the hydraulic station, the pull plate device, the chain drive device. The electrical part is composed of hydraulic station, pulling plate device and chain transmission device. The working principle of chamber filter press is as follows: when the pressing machinery presses, high pressure oil is supplied by the hydraulic station, and the pressing plate slowly presses the filter plate, when the pressing force reaches the pressure value set by the relief valve, the filter plate is pressed, and the relief valve starts to unload, at this time, the power supply of the motor is cut off, and the pressing action is completed, and when the pressure is kept automatically. The filtrate is transported to the filter chamber inside the filter plate of the filter press by the sludge pump, and each filter plate is equipped with a water nozzle on the lower outlet hole, and the filtrate intuitively flows out from the water nozzle, and the filter chamber consists of concave-convex filter frames, and the filter cloths are fixed to the plate frames. The sludge is kept inside the filter chamber, and when the filtering pressure increases, the sludge inside the chamber is pressed into mud cake. The main advantage of chamber filter press is that it is easy to replace the filter cloth, and the disadvantage is that the filter plate is easy to be damaged. Yixing Huarun Thermal Power Co., Ltd. wastewater system chamber filter press model ) (MZFl25 / 920 a UB, originating from Hangzhou, Zhejiang Province, the filter plate is made of polypropylene, the filtration area of 125m2, the current operating conditions are good.

Analysis of common faults in the use of chamber filter presses

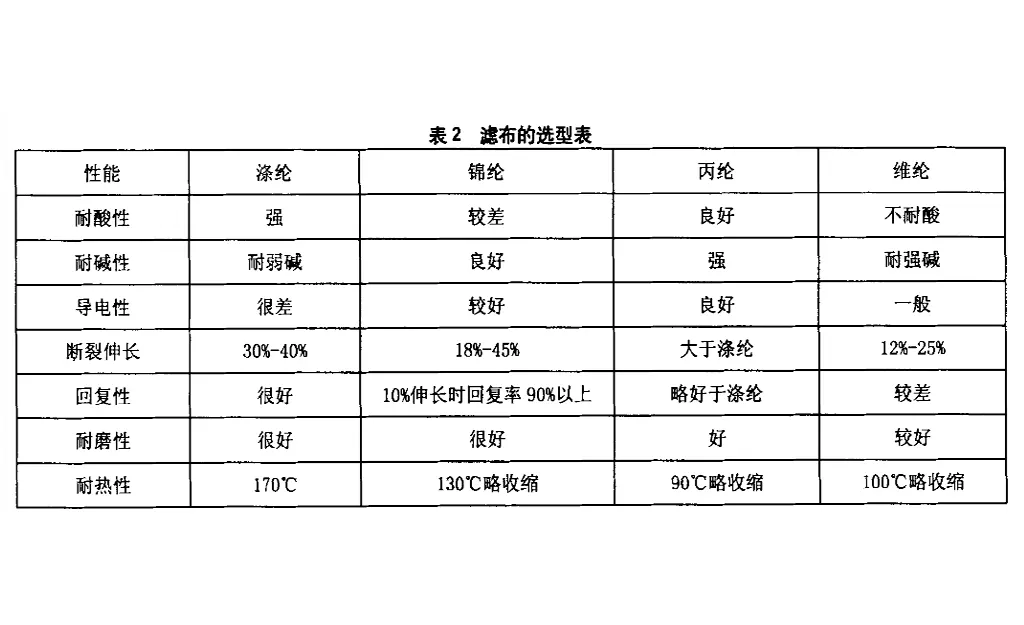

Damage to the filter cloth The holding pressure of the electrical pressing parts of the chamber filter press is maintained at 20 MPa. Sludge transfer pump conveying pressure is usually 0.5-0.8Mpa, in the filter press filtration process, the sludge dewatering rate in the filter chamber will be higher and higher, and the filter cloth filter eyes with the decline in filtration capacity and blockage, under the pressure of the material transfer pump, easy to make the filter cloth damage. At the same time, the selection of filter cloth and the quality of processing also plays a key role in the service life of the filter cloth. Filter cloth is usually divided into polyester, cotton, nylon and other materials, the performance of different filter cloth on the pH value of wastewater, solid content size and other indicators of the degree of adaptability, and the filter press operating results of the most important selection of the appropriate filter cloth, such as the selection of the inappropriate filter cloth will appear in a short period of time broken filter cloth, filtering channel clogging, sticking to the board and other issues.

The most critical indicators of the service life of the filter cloth are the characteristics of the filter medium and the quality of the filter cloth, in addition to selecting the filter cloth suitable for the nature of the filter medium, the quality of the filter cloth is also the most important indicator of the impact of filtration effect, the new filter cloth should be checked before the installation of the surface of the filter cloth whether there are scratches, whether the cloth is aging, and check the filter cloth stitching line whether the needle is off or whether the stitching is too large. After 70 rows of filter cloth, we need to pay attention to whether the filter cloth expansion and contraction leads to the rupture of the filter cloth, the stitching line is disconnected and the pinhole gap is increased. The stitching line pinhole is very easy to become bigger after the filter cloth is compressed and stretched, and the bigger pinhole will directly reduce the filtering effect.

For our wastewater system in the existence of a larger amount of sludge, pH value is lower, the required telescopic requirements of higher requirements for the filter material requirements, after a trial selection of polyester material, its high strength, water permeability is good. The service life can reach more than 2400 hours, sludge sticky cloth performance is good.3.2 Pulling the plate mechanism failure filter press pulling the plate mechanism is one of the most frequent use of the filter press, mainly used for unloading operation of the filter plate, prone to failure phenomenon. The most common failures are: the robot can not pull the filter plate, the two sides of the robot is not synchronised, pulling the plate chain jams, mechanical fingers can not be popped up and so on. The main solutions are: pull the plate motor friction plate is tight enough, but when the loose pull the plate motor friction plate has been enhanced pull the plate manipulator pull, but the friction plate can not be adjusted too loose, the manipulator pull too much will make the polypropylene filter plate puller damage; manipulator is not synchronised with the need to adjust the proximity switches, travel switches and pull the height of the plate chain; pull the plate chain astringent need to timely maintenance of the pull the plate chain, the pull plate chain due to acid water corrosion of the chain pitch, the pull the plate chain is not easy to maintain. Acidic water corrosion chain pitch is very easy to corrosion jams lead to normal drive; at the same time, pull the plate manipulator rollers and springs also need to strengthen the maintenance, found that the spring breaks need to be replaced in a timely manner spring.

Routine maintenance of filter presses

Cleaning of filter clothThe effect of filter press operation mainly depends on whether the filter cloth filtration is smooth. Whether the mud biscuit degree is good, which requires the filter cloth in the use of a certain period of time after the cleaning, because the filter cloth in the use of the process of filtering the eyes will be longer with the running time and blockage, resulting in a gradual decline in the filtration capacity of the filter cloth. The selection of filter cloth should refer to the filter sludge characteristics, pH value, sludge transport volume and other parameters to determine the type of filter cloth.

Running parts of the maintenance of the filter press in the use of the process, the need for lubrication of moving parts, moving parts are mainly for the pull plate chain, piston rod, roller, flap bearings, pulling the plate manipulator and springs, etc.; due to the process of cleaning the filter cloth, the water spray will have a direct impact on the surface of the parts of the filter press, is very easy to cause corrosion, the press filter in the normal operation of the parts need to be kept dry.

Filter plate cleaning hydraulic system maintenance often check the sealing surface of the filter plate to ensure that it is clean, clean, use the filter cloth to check whether the filter cloth is folded to ensure that it is flat and intact. Maintenance of the hydraulic system is mainly on the hydraulic cylinder tank level, hydraulic components and each of the various connection port sealing inspection and maintenance, while ensuring the cleanliness of the hydraulic oil.

Filter press operation control

Inspections before the use of the filter press to check whether the filter plate is damaged, whether the filter plate is clean, and whether the placement meets the requirements: check whether the filter cloth is folded, whether there is any damage, and whether the filtration performance is good: check whether the various lubrication and cooling equipment is in line with the requirements of the drive; check whether the connections are tight, and whether there is any leakage: check whether the oil pressure of the filter press is sufficient, and whether the oil level is in line with the requirements; test the pH value of the filter press feed sludge to see whether the pH value of the filter press is suitable.

Filter press process control After starting the pressing device, the filter press enters the automatic pressure preservation state, and the progress of filter press is controlled when filter press starts. Check whether the filter nozzles are smooth, and there is no gap between the filter plates and no sludge leakage. Check the filter plate with turbid water, stop filtering if necessary to check whether the filter cloth is broken, and repair or replace it in time if it is broken.

Unloading process control When the feed pressure is close to the sludge pump conveying pressure, and the water output from the filter plate nozzle becomes obvious, the unloading conditions are already in place. The pressure plate piston can be back in place, start pulling the plate trolley to start unloading. After unloading, check whether the filter cloth is neat and intact, such as filter cloth residues of adhesive sludge need to clean or replace the filter cloth.5.4 Filter press operation precautions:

When the filter press is holding pressure, it must ensure that the filter plate is flat, there is no debris between the filter plates, and the filter cloth is even. As the pressure of the filter press will reach 20MPa when it is holding pressure, such as the unevenness of the filter plate of the filter press will easily lead to bending and damaging the axle of the pressing device and damaging the filter plate during the process of holding pressure, meanwhile, the debris of the filter plate can make the sludge pump leak during the operation of the sludge pump, so that the filtration press operation cannot be carried out.

Filter press in the pressure, the feed pressure must be controlled in the factory nameplate marked on the maximum filtration pressure (gauge pressure) below, otherwise it will affect the normal use of the machine; 5.4.3 filtration began, the feed valve should be opened slowly, at first the filtrate tends to be more turbid, and then clear, is a normal phenomenon; 5.4.4 in the rinsing of the filter cloth and the filter plate, pay attention to do not let the water splash to the oil tank power supply:

When carrying and replacing the filter plate, the force should be appropriate to prevent collision damage, and it is forbidden to drop or hit, so as not to rupture the filter plate/frame. The position of the filter plate should not be put in the wrong place; do not take down the filter plate without authorisation when filtering, so as to avoid accidents due to insufficient stroke of the cylinder; after the rupture of the filter plate, it should be replaced in time, and should not continue to be used, otherwise it will cause the rupture of other filter plates;

If the equipment is not used for a long time, the filter plate should be cleaned and the filter cloth should be cleaned and dried.

reach a verdict

Filter press can be widely used in coal-fired thermal power plant water treatment process of sludge drying process, its sludge dewatering effect can be comparable to the dewatering machine, and lower investment costs, operation and maintenance is relatively simple. Yixing China Resources Cogeneration Co., Ltd. wastewater treatment system using chamber filter press process, sludge drying effect is good, filter drying after the sludge cake forming rate of 100%, the water content is usually 30%, solid-liquid separation effect is obvious. Therefore, for the sludge characteristics of sewage treatment production, select the corresponding filter press can also achieve better dewatering efficiency and sludge treatment capacity, at the same time, the operation of the filter press in the routine maintenance and maintenance of the importance of the filter press can not be ignored.

Disclaimer: The copyright of this article belongs to the original author and the original source.

Welcome to call us for consultation, technical exchange, and material experiment.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses