![]()

In the coal gasification industry, the gasification filter cake is usually blended into the power coal for blending and use, but because of the high water content of the filter cake, direct blending will cause power coal plugging. In order to reduce the risk of power coal blending and plugging, it is necessary to further reduce the water content of the filter cake. Plate and frame filter press can well reduce the water content of the cake, so to ensure the stable operation of the plate and frame filter press. Based on this to discuss the common problems in the operation of the plate and frame filter press and treatment measures.1 Common Solid-Liquid Separation Equipment Introduction to 4 common types of solid-liquid separation equipment.

1 Vacuum Belt Filter Through the coordinated operation of the rotary motor, reducer and haul-off rollers, the Vacuum Belt Filter can effectively utilise the pressure change of the material and the maximum vacuum it brings to achieve solid-liquid separation. In addition, the filter cloth is mounted on the belt to better fulfil the entire filtration process. The connection of an annular friction belt and a water seal allows the tracks to slide effectively between the vacuum bins. At the same time, by connecting the vacuum equipment, a vacuum filtration zone can be constructed on the surface of the track, and a large amount of slurry can be smoothly transferred to the filter cloth.

1.2 Disc Vacuum FilterThe disc vacuum filter has excellent filtration performance, which can effectively separate the slurry from other materials and achieve more efficient filtration by changing the vacuum flow rate. In addition, disc vacuum filter also has a series of latest technology, such as adjustable agitator, adjustable exhaust device, adjustable filter disc guide frame.

1.3 Screw discharge sedimentation centrifugeScrew discharge sedimentation centrifuge is a centrifugal sedimentation to achieve the purpose of completely separated from the natural fluid, mainly used for solid-phase dewatering. Theoretically, the spiral discharge sedimentation centrifuge utilises the principle of density difference between the solid and liquid phases, and the liquid phase produced is clearer and the water content of the solid phase is less.

1.4 Plate and frame filter presses are made of many filter plates with striped patterns and filter frames that are assembled into a machine after regular display. Plate and frame filter presses are usually operated intermittently and have a relatively low capacity. However, plate and frame filter presses usually have a strong filtration drive and produce a dry filter cake that can beRecycling.

2 Plate and frame filter press operation process

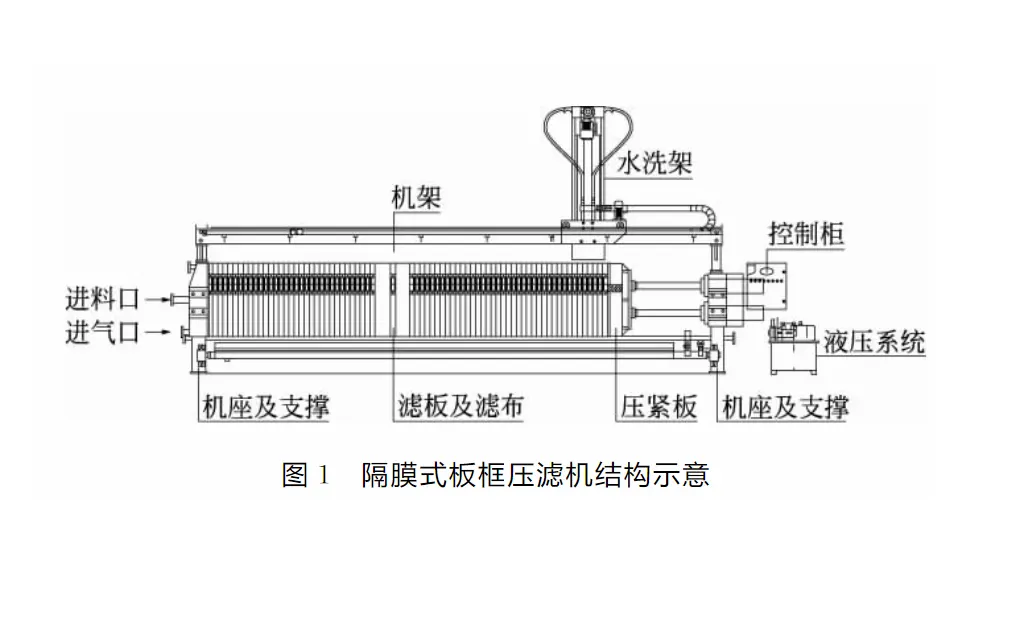

2.1 Plate and frame filter press systems Plate and frame filter press systems include slurry tanks, feed pumps, filter press thrust plates, filter plates, main beam machines, press tanks, press pumps, cloth washing tanks, cloth washing pumps, belt conveyors, compressed air tanks, instrument air tanks. hold down plate saddle cylinder electronic control cabinet Hydraulic station diagram5 PLATE AND FRAME FILTER PRESS CONSTITUTIONAL PARTS The plate and frame filter press consists of a plurality of parts, including a thrust plate, a main beam, a pressurised plate, a manual pulling plate system, a machine base, an electric control cabinet, a hydraulic control system, a water-washing filter cloth apparatus, a flap apparatus, a filter cloth, a discharge port, a diaphragm press and a filtrate discharge device, as well as a population and an outlet for slurry, and equipment for connecting the filter cloth and water. By means of an efficient slurry conveying system, a closed space is created between the two filter plates of the filter press in order to generate a high pressure and effectively isolate the filtrate and cake.

2.2 Plate and frame filter press operation process

(1) Feeding: when the slurry is added to the storage tank, the plate and frame filter press pushes the slurry through the pressure to flow into the filter chamber composed of multiple filter plates, and eventually fills the whole chamber to form a thick layer of filter cake.

(2) Filter Cake: As the material flows, this layer of filter cake is extruded and eventually sent by the belt conveyor to the vehicle that pulls the filter cake, which is collected and used for power coal blending.

(3) Filtrate: After the slurry is dewatered by the filter press, the clear liquid is discharged from the filter press and flows to the grinding pool.

(4) Filter plate group: a group of adjacent and positioned filter plates, installed between the press plate and thrust plate of the filter press.

(5) Diaphragm pressing: water is pressed and delivered to the diaphragm plate, causing the diaphragm chamber to expand, further discharging the filtrate remaining in the cake by shortening the volume of the filter chamber.

(6) Flap device: In order to make the filtrate, filter cloth rinsing water does not flow into the filter cake, conveying track, receiving car, the flap device through the hydraulic cylinder expansion and contraction action, in the filter cake discharged before the opening of the flap, the filter cake discharged after the closure of the flap ̈.

3 Plate and frame filter press operation common faults and treatment

3.1 insufficient oil pressure oil pressure is insufficient to generate the causes of oil pressure pump (see Figure 6) relief valve failure, oil pump failure, valve block and joint leakage, oil red seal aging, valve seepage or oil level is too low. Treatment measures for the faulty parts of the repair or replacement.

3.2 Pressing pressure is low pressing pressure is low mainly for the press pump pressure is not enough, can not carry out the next procedure. Causes are mostly cracked filter press water pipe, press tank level empty, press pump failure, instrumentation valve failure can not be opened and so on. Treatment measures are generally replaced, repaired or contact the instrumentation staff to deal with the valve.

3.3 between the filter plate leakage filter plate leakage is usually caused by the feed pump pressure and flow is too large, resulting in filter plate, diaphragm sealing surface m now dirt, filter cloth is not smooth with folds, and oil pressure instability. Treatment measures for readjustment of the feed pump and clean up the filter cloth, adjust the oil pressure to the same as appropriate.

3.4 Filter plate breakage Filter plate breakage is caused by damage to the filter cloth, resulting in incomplete filling of the filter with cake, excessively high loading rates, obstruction of the inlet pipework to the filter plate and diaphragm, and obstruction of the air vent valve. Measures taken include: replacing the filter cloth in a timely manner to ensure that the filter cake fills the chamber for pressing; slowing down the feed rate; cleaning the holes in the feed hopper; and keeping the inside of the filter plate clean.

3.5 Upward lifting of the filter plate The reason for upward lifting of the filter plate is that the installation foundation is not stable or the lower part of the filter plate is not clean of slag. The treatment measures are to re-grade the foundation and remove the slag under the filter plate.

3.6 The filtrate is not clear and the plate and frame feed time is long the filtrate is not clear and the plate and frame feed time is long the production of the original Gang may be a broken filter cloth, screen size deviation, screen joints have cracks, pipeline leaks, and the feed pump operation problems (such as impeller fall off or the feed pump outlet valve is not open). The treatment measures are to check and replace the filter cloth and eliminate the defects or leaks in the equipment and pipelines.

3.7 hydraulic system noise hydraulic system noise may be the cause of suction air, loose fasteners, hydraulic oil viscosity is too large, return filter clogging. Treatment measures to open the exhaust valve to ensure that the fasteners are firm, reduce the viscosity of the hydraulic oil.

3.9 Filter press inoperative Filter press inoperative is caused by the limit of the filter press itself, as well as the failure of the press pressure gauge to reach the set minimum value. Treatment measures is to contact the transport and maintenance personnel to make adjustments in a timely manner.

3.10 Clogging of the filter cloth Over time, the filter cloth of the filter press may become clogged. When the filtration time is significantly shortened, the water in the cake is significantly reduced, the instantaneous filtration pressure of the filter press is significantly increased, which leads to a significant acceleration of the liquid time, then the filter cloth must be cleaned. Usually the original filter cloth is removed and then re-cleaned, but this practice is time-consuming and labour-intensive. South of the traditional cleaning method there are large defects, such as cleaning pressure is small, the requirement of cleaning the surface smooth, etc., the cleaning efficiency is low. For this reason, this system adopts automatic filter cloth rinsing device, installed in the upper part of the filter press rinsing mechanism, the use of high-pressure water shunts to a number of nozzles, through the rinsing device of the programme control system, lifting device, and the automatic pulling plate system of the filter press, and jointly on the installation of the filter cloth on the filter plate rinsing one by one.

3.11 Other fault judgement

(1) The feed pump feeds for a long time, the feed pressure is not enough, and the discharged filtrate is seriously entrained with black water. Possible causes are broken filter cloth and leakage in pipeline. At this time, the pipeline, filter cloth should be immediately checked and eliminated.

(2) The feed pump can be operated, but the level of the slurry tank drops slowly, and the feed pressure is not under pressure. Possible reasons for the feed pump impeller off or the valve outlet is not open. Treatment measures for timely inspection of the feed pump operation.

(3) pressure on the process does not go to the pressure, may be due to oil leakage at the pipeline, the pump station hydraulic oil level is too low, oil pump failure, check valve damage, cylinder sealing damage, and so on.

(4) The pipeline and cylinder seal is not good, the check valve and solenoid ball valve is damaged, there may be pressure after the pressure does not hold pressure.

(5) Pressure gauge damage or loose wiring in the process of compression, may appear to reach the upper limit of pressure but the compression process does not stop.

(6) If the plate and frame filter press is not configured with the number of plates according to the nameplate of the filter press during operation, the oil pump may stop without reaching the upper pressure limit during operation.

(7) The pull plate trolley and chain are stuck by foreign objects, which will cause the pull plate trolley abnormal. In daily work, oil the chain and runway regularly to ensure that the lubrication parts are good.

4 Conclusion In summary, mechanical leakage, procedural errors and other problems are more likely to occur during the operation of the plate and frame filter press, and the optimisation of treatment measures for the above problems will help to solve the problems and ensure the stable operation of the system. In the future, it is also necessary to optimise the process of the plate and frame filter press itself and improve the technical level of the operators to ensure the long life cycle of the plate and frame filter press system.

Author: Ma Xiaogang Zhang Ying Ma Xiaogang, Zhang Ying

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses