Filter press cloth is an important part of the filter press, and its performance directly affects the filtering effect of the filter press. With the growth of the use of time, the filter cloth will accumulate more and more impurities and dirt, affecting its filtration performance. Therefore, regular washing of the filter cloth is an important measure to maintain its filtration performance. In this article, we will introduce in detail the washing methods, techniques and precautions of filter press cloth, which will help you wash the filter cloth correctly and effectively, prolong its service life and improve the filtration effect.

I. Washing method of filter cloth

1. Manual rinsing: Manual rinsing is the simplest method, applicable to a small amount of filter cloth rinsing. The specific operation method is to use a soft brush or sponge dipped in the appropriate amount of cleaning agent, gently brush the surface of the filter cloth, and then rinse with water. Be careful not to use too rough cleaning tools, so as not to damage the surface of the filter cloth.

2. Mechanical rinsing: Mechanical rinsing is a more efficient way of rinsing and is suitable for rinsing large quantities of filter cloth. Through professional cleaning equipment, such as washing machine or high-pressure cleaning machine, the use of high-pressure water and cleaning agent to rinse the filter cloth. This method of rinsing effect is better, but need to pay attention to the maintenance of equipment and cleaning agent selection.

3. Ultrasonic cleaning: Ultrasonic cleaning is a rinsing method that uses ultrasonic vibration to shake dirt off the surface of the filter cloth. Put the filter cloth into the ultrasonic cleaning machine, add the appropriate amount of cleaning agent, start the equipment can be. Ultrasonic cleaning is more effective, but for some stubborn stains may need to be cleaned several times.

Second, the filter cloth rinsing techniques

1. Use the appropriate cleaning agent: according to the material of the filter cloth and the nature of the stains to choose the appropriate cleaning agent, avoid the use of too harsh or corrosive cleaning agent, so as not to damage the filter cloth or shorten its service life.

2. Control the rinsing time: do not soak or over-rinse the filter cloth for a long time, so as not to cause deformation or damage to the filter cloth. In general, rinsing with water for 10-15 minutes is sufficient.

3. Regular inspection and replacement of filter cloth: regularly check the integrity and use of the filter cloth, and replace it in time if it is damaged or the filtration performance decreases, so as not to affect the filtration effect and service life of the filter press.

4. Pay attention to the temperature and pressure: in the flushing process, appropriate adjustment of temperature and pressure can improve the flushing effect, but be careful not to be too high or too low, so as not to damage the filter cloth or affect its performance.

5. Classification cleaning: for different types of filter cloth, such as polyester, nylon, polypropylene, etc., should be classified cleaning, to avoid mixing and washing caused by filter cloth damage or shorten the service life.

C. Precautions for filter cloth rinsing

1. Safety first: In the cleaning process, attention should be paid to safe operating procedures to avoid accidents caused by improper operation. For example, contact with cleaning agents or high-temperature water should be avoided during operation to avoid scalding or chemical corrosion.

2. Avoid irritating cleaning agents: When choosing cleaning agents, avoid irritating cleaning agents, such as strong oxidising agents like acid, alkali, chlorine or bleach. These chemicals may cause skin or eye irritation or damage.

3. Pay attention to environmental protection: in the cleaning process, attention should be paid to the treatment and discharge of waste water to avoid pollution of the environment. For some toxic and harmful cleaning agents, they should be properly disposed of and recycled in accordance with relevant regulations.

4. Keep equipment and tools clean: During the cleaning process, equipment and tools should be kept clean to avoid cross-contamination or causing secondary contamination. For some equipment and tools that are prone to breeding bacteria or mould, they should be disinfected or replaced regularly.

5. Do a good job of record-keeping and maintenance: for each cleaning process and results should be well documented and maintained, in order to find problems and improve measures in a timely manner. At the same time can also extend the service life of the filter cloth and improve the filtration effect.

6. Master the correct use method: In the process of using the filter press, the filter cloth should be used correctly in accordance with the relevant regulations and operating procedures. Correct use can reduce the wear and tear of the filter cloth and the accumulation of dirt, thus prolonging its service life and improving the filtration effect.

7. Selecting the correct cleaning methods and procedures for different types of filter cloths: Filter cloths of different materials and constructions require different cleaning methods and procedures. For example, some filter cloths require special cleaning agents or need to be cleaned at specific temperatures and pressures. Therefore, when cleaning filter cloths, you need to choose the right cleaning method and procedure according to the actual situation.

8. Regular inspection and maintenance: Regular inspection and maintenance of the filter press and its filter cloth can ensure its normal operation and use effect. For example, check whether the filter cloth is broken, folded or clogged, etc., and repair or replace the problematic filter cloth in time; also pay attention to checking whether the sealing performance of the filter press, the hydraulic system and other components are working properly.

9. Maintaining environmental hygiene: Maintaining environmental hygiene around the filter press reduces the accumulation of dust, dirt and other impurities, thereby reducing contamination and clogging of the filter cloth. It also reduces wear and tear and maintenance costs on the filter press and other components.

10. Training of operators: Professional training and education are required for the operators of the filter press, so that they can understand the working principle, operating procedures and maintenance knowledge of the filter press. Only qualified operators can correctly use and maintain the filter press and its filter cloth, prolong its service life and improve the filtration effect.

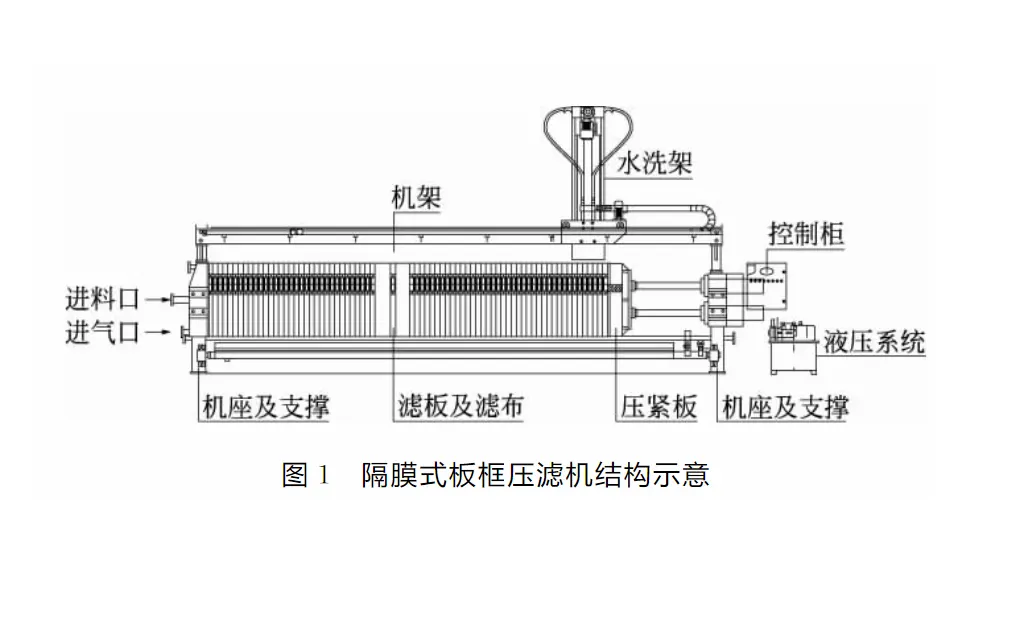

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses