Filter presses and hydraulic cylinders are two different kinds of mechanical equipment, and they both have a wide range of applications in the industrial field. Although they both work by pressure, there are some obvious differences in their working principles, applications and uses. In this article, we will introduce the differences between filter presses and hydraulic cylinders in detail to help you better understand these two types of equipment.

I. Principle of operation

Filter Press: Filter press is a mechanical equipment that uses filter cloth for filtration. It conveys liquid into the filter cloth through a high-pressure pump, and after the liquid is filtered through the filter cloth, the solid particles are retained on the surface of the filter cloth, and the liquid flows out through the filter cloth. The main working principle of the filter press is to use the pressure generated by the high-pressure pump to force the material through the filter cloth, so as to achieve solid-liquid separation.

Hydraulic cylinder: Hydraulic cylinder is a kind of mechanical equipment that uses hydraulic oil to transmit power. It consists of a cylinder, piston rod and seals, etc. Through the action of high-pressure oil, the piston rod reciprocates or rotates in the cylinder. The main working principle of the hydraulic cylinder is to use the pressure generated by the high-pressure oil to push out or pull back the piston rod to achieve mechanical movement.

II. Scope of application

Filter Press: Filter press is mainly used in the field of solid-liquid separation, such as solid-liquid separation and purification in sewage treatment, chemical, pharmaceutical, food, metallurgy and other industries. It can separate the solid particles in liquid or separate the liquid in solid, so as to achieve the purpose of purification or concentration.

Hydraulic Cylinders: Hydraulic cylinders are used in a relatively wide range of applications, including but not limited to the following areas:

1. Industrial automation: Used for driving and controlling all kinds of robotic arms, CNC machine tools and other equipment.

2. Construction machinery: used for the transmission and control of excavators, loaders, bulldozers and other equipment.

3. Agricultural machinery: for transmission and control of equipment such as tractors and harvesters.

4. Marine industry: Used for the transmission and control of equipment such as rudders and anchors of ships.

5. Military industry: used for transmission and control of equipment such as tanks and armoured vehicles.

III. Uses

Filter Press: The use of filter press is mainly for solid-liquid separation and purification. Through the use of filter presses, solid particles in the liquid can be retained on the filter cloth, or the liquid in the solid can be separated, so as to achieve the purpose of purification or concentration. For example, in the field of wastewater treatment, filter presses can be used to separate suspended matter in wastewater; in the field of chemical engineering, filter presses can be used to separate solid-liquid mixtures after chemical reactions.

Hydraulic Cylinders: The purpose of hydraulic cylinders is mainly to transmit power and achieve mechanical movement. Through the use of hydraulic cylinders, you can use the role of high-pressure oil, the piston rod will be pushed out or pulled back, so as to achieve mechanical movement. For example, in the excavator, the hydraulic cylinder can be used to control the excavator's arm telescoping; in the CNC machine tool, the hydraulic cylinder can be used to achieve rapid feed and precise positioning of the tool.

Filter presses and hydraulic cylinders, although both mechanical equipment working through pressure, but there are obvious differences in the working principle, application scope and use. Filter press is mainly used in the field of solid-liquid separation and purification, the use of filter cloth for filtration, solid-liquid separation; while the hydraulic cylinder is mainly used for transferring power and mechanical movement, the use of high-pressure oil to achieve the reciprocating or rotary movement of the piston rod. In the actual application, you need to choose the right equipment according to the specific needs and scenes.

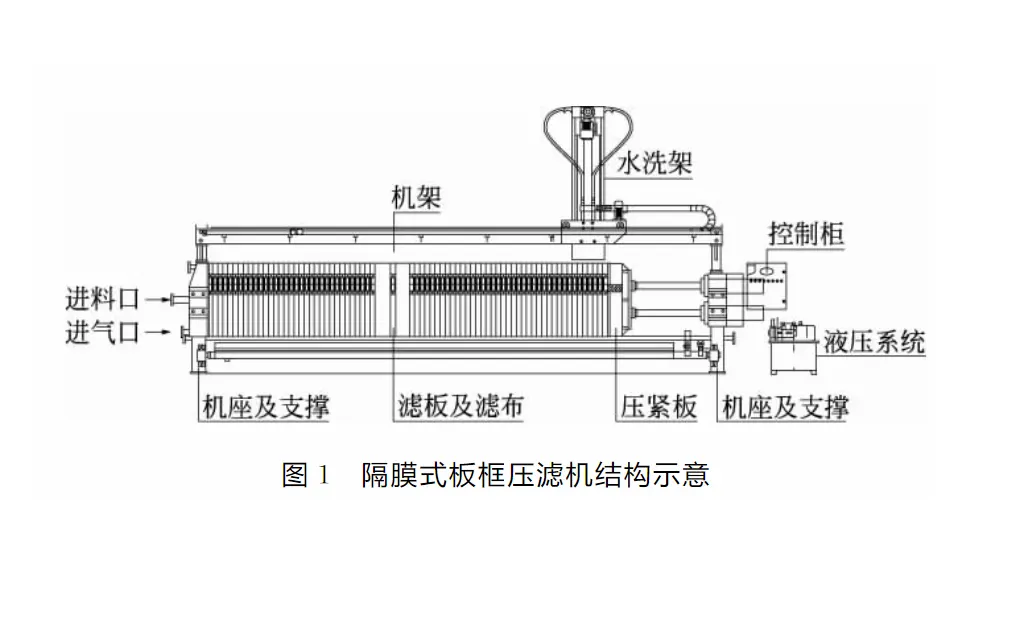

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses