Filter press is a kind of mechanical equipment widely used in solid-liquid separation, and special oil is an important guarantee for the normal operation of filter press. In this article, we will discuss in detail the role, types and selection criteria of special oil for filter presses to help you better understand this field.

I. The role of special oil for filter presses

1. Lubrication: the special oil forms a lubricating film between the moving parts of the filter press to reduce friction resistance and wear and tear, thus prolonging the service life of the equipment.

2. Cooling effect: special oil can absorb the heat generated by mechanical operation, play a cooling effect, to maintain the equipment at a suitable temperature for work.

3. Sealing effect: the special oil plays a good sealing effect in the sealing part of the filter press, preventing the medium from leaking and outside impurities from entering.

4. Shock absorption: special oil has a certain shock absorption function, can absorb mechanical vibration, reduce noise, improve the smoothness of equipment operation.

II. Types of special oil for filter presses

According to different classification criteria, filter press specialised oils can be classified into various types. The following are the main classifications:

1. Classification according to working medium: According to the nature of the materials handled by the filter press, special oil can be divided into water-based special oil and oil-based special oil. Water-based special oil is suitable for water media or materials in contact with water, while oil-based special oil is suitable for oily media or materials in contact with oil.

2. Classification according to performance characteristics: According to the performance characteristics of special oils, they can be classified into anti-wear type, extreme pressure type, anti-oxidation type and so on. Antiwear speciality oil has good antiwear performance and is suitable for filter presses with high loads; extreme pressure speciality oil has good extreme pressure performance and is suitable for filter presses working under high friction conditions; antioxidant speciality oil has good antioxidant performance and can extend the service life of the oil.

3. Classification according to viscosity: according to the viscosity of special oil, it can be divided into low viscosity, medium viscosity and high viscosity special oil. Low-viscosity special oil has good fluidity and is suitable for high-speed operation of the filter press; medium-viscosity special oil has good comprehensive performance and is suitable for most of the filter press; high-viscosity special oil has good adhesion and carrying capacity and is suitable for heavy-duty and low-speed operation of the filter press.

Third, the selection criteria of special oil for filter presses

Selection of the right special oil for filter presses is critical to the proper operation of the equipment. The following are the selection criteria:

1. Meet the requirements of the equipment: according to the model, performance parameters and working conditions of the filter press, choose the special oil that meets the requirements of the equipment. If special performance requirements are needed, consult with professional suppliers.

2. Good lubrication performance: choose the special oil with good lubrication performance, can reduce friction resistance, reduce wear and prolong the service life of the equipment. Good lubricating properties of the special oil can also improve the working efficiency of the equipment.

3. Good cooling performance: Choose a special oil with good cooling performance, which can effectively absorb the heat generated by the operation of machinery and keep the equipment working at a suitable temperature. This helps to prevent equipment failure caused by overheating.

4. Good sealing performance: selecting special oil with good sealing performance can effectively prevent the medium from leaking and outside impurities from entering. This helps to improve the reliability and safety of the equipment.

5. Good vibration-damping performance: Selecting special oil with good vibration-damping performance can effectively absorb mechanical vibration, reduce noise and improve the smoothness of equipment operation. This helps to improve the comfort of the equipment and prolong the service life of the equipment.

6. Suitable viscosity: Select the special oil with suitable viscosity according to the actual needs of the filter press. Too high or too low viscosity may affect the normal operation and performance of the equipment. Generally speaking, medium viscosity special oil has good comprehensive performance and applicable range.

7. Brand reputation and quality assurance: Choose special oils provided by well-known brands or suppliers with good reputation to ensure reliable product quality and stable performance. Attention to the quality assurance period and service life of the product is also one of the important factors for selection.

8. Economic considerations: under the premise of meeting the performance requirements, choose a reasonably priced and affordable special oil. Avoid blindly pursuing low prices while ignoring the importance of product quality and performance. Reasonable planning of maintenance costs and extension of oil life are also key factors in reducing overall operating costs.

Filter press special oil is an important guarantee to ensure the normal operation of the filter press. In the process of selection and use, its role, type and selection criteria should be fully considered. Selecting the appropriate special oil according to the actual needs and working conditions, and following the correct use of maintenance methods, will help improve the overall performance and extend the service life of the equipment. Paying attention to the industry development trend and technological innovation, continuously optimising and perfecting the lubrication system of filter press is one of the key elements to achieve efficient and stable filtration.

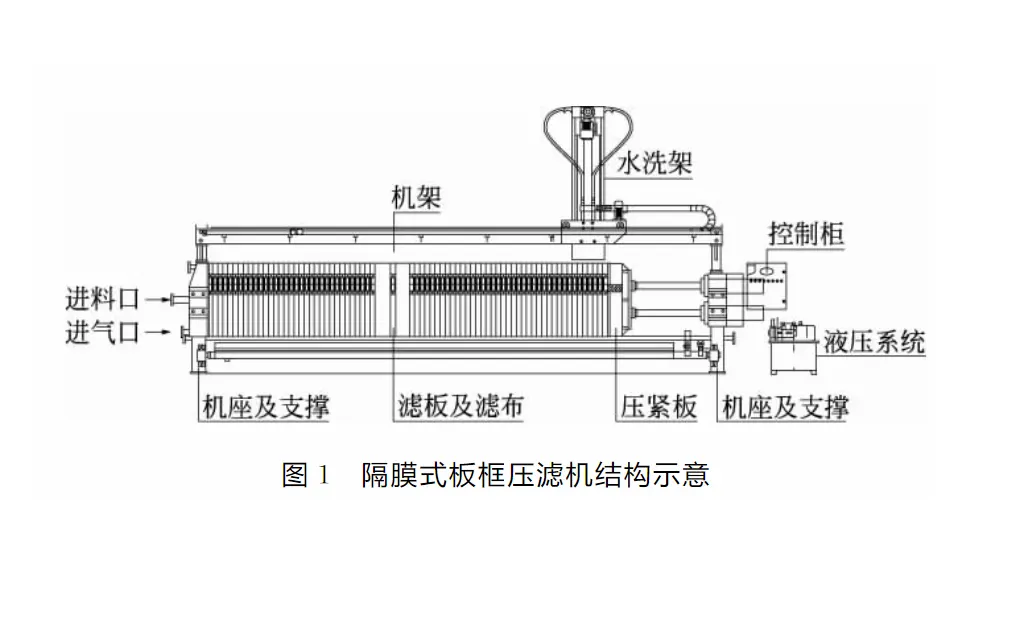

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses