1 Project Overview

Shanxi Coking Coal Group Limited Liability Company Ximing Mine currently has two sets of mine wastewater treatment system, two sets of systems with a total treatment capacity of 5000m3 / d, the treatment process for the "cyclone clarification + filtration", the treated water basically meets the water quality standards for fire sprinkler water. However, with the increase of national environmental protection and the increase of mine water influx, the previous two sets of mine wastewater treatment system can't meet the current treatment water quantity and quality requirements, and the previous two sets of mine wastewater treatment system has been in use for more than ten years, the equipment is aging seriously, the treatment efficiency and treatment capacity can't reach the original design level, the original design of sand sedimentation tank and adjusting tank are small, which brings a lot of problems to the subsequent treatment process. The original design sand sedimentation tank and conditioning tank are small, which brings a lot of problems to the subsequent treatment process. In view of the above situation, the current water treatment system of Ximing Mine was comprehensively renovated and the subsequent treatment process was increased, so that the final quality of produced water could reach the water quality standard of Class III in the Environmental Quality Standard for Surface Water.

2 mine water treatment upgrading and transformation ideas

2.1 Design water volume According to the data provided by Ximing Mine, the water treatment station after the transformation of the mine water treatment system should have a treatment water volume of 9,000m3/d. After comprehensive consideration, it is determined that the final treatment volume is 10,000m3/d.

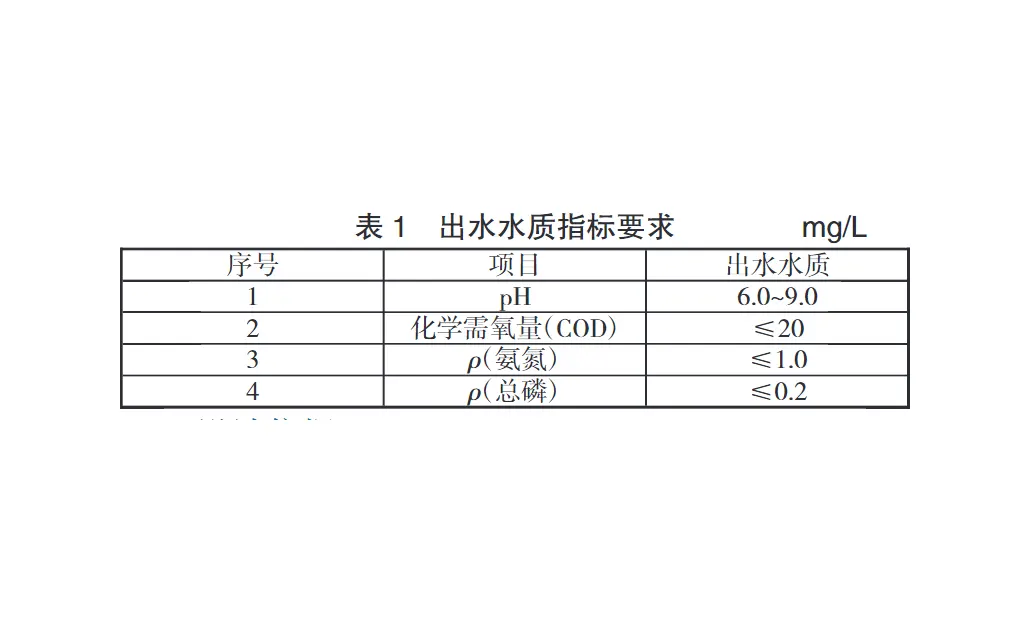

2.2 Design of inlet and outlet water quality According to the raw water quality report provided by Ximing Mine, it can be seen that the pollutants exceeding the standard are mainly COD, BOD5, total nitrogen and fluoride, of which COD and BOD5 are mainly exceeding the standard. The treated water can be directly discharged or reused underground, and the quality of the effluent water is controlled according to the water quality standard of Class III in the "Environmental Quality Standard for Surface Water", and the requirements of water quality indexes are shown in Table 1.

2.3 Design basis design basis mainly includes "Environmental Protection Law of the People's Republic of China"; "Law of the People's Republic of China on the Prevention and Control of Water Pollution"; "Environmental Quality Standards for Surface Water" (GB3838-2002); "Comprehensive Sewage Discharge Standards of Shanxi Province" (DB14/1928-2019); "Design Code for Outdoor Drainage Design Code (GB50014-2014); Design Code for Coal Mines; Design Code for Underground Coal Mine Firefighting and Sprinkler (GB50383-2006); Design Code for Pumping Stations (GB/T50265-2010); and relevant information and water quality test reports provided by the owner. information and water quality laboratory report provided by the owner.

3 Analysis of treatment process flow after modification

3.1 Principles of selection of technology programmes in the selection of water treatment processes generally consider the following aspects: whether the process can meet the requirements of the water indicators; whether the process is reliable; the cost of the process programme; whether the operation and management is convenient; high and low operating costs.

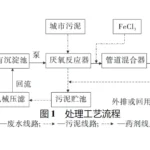

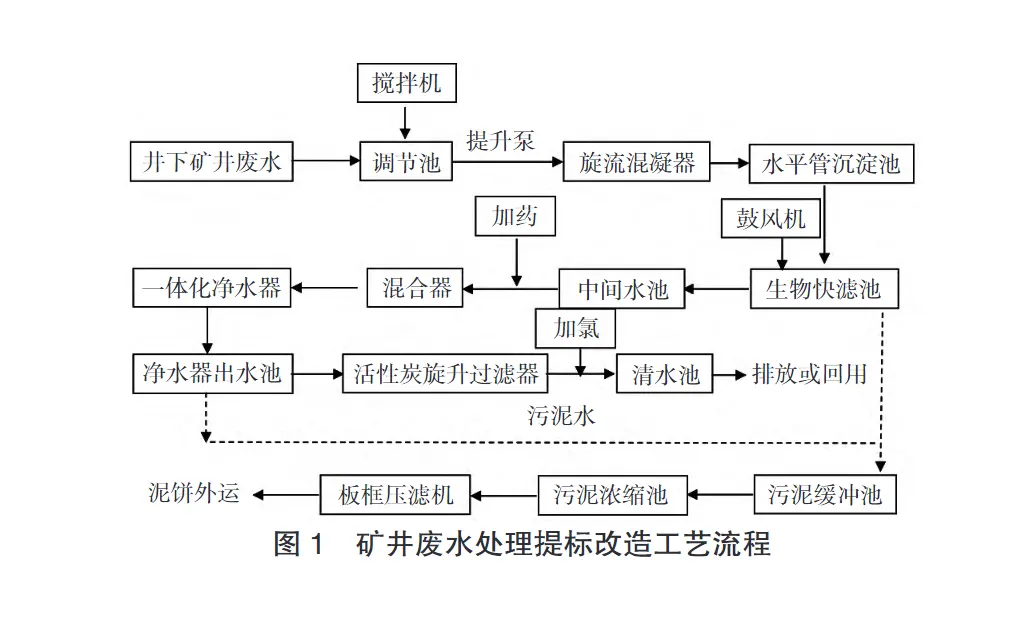

3.2 Treatment process and flow analysis of mine wastewater treatment upgrading process shown in Figure 1, mine wastewater first into the regulating tank, and then lifted to the cyclone coagulator through the lifting pump to remove most of the sand particles in the water, and make the medicine and wastewater fully mixed, coagulant effluent into the horizontal pipe sedimentation tank, through the horizontal pipe sedimentation to remove most of the suspended solids in the water, the effluent is self-flowing into the biological fast filtration tank, in the fast filtration tank for aeration to remove COD and ammonia nitrogen, the fast filtration tank effluent into the intermediate pool, through the intermediate lifting pump to lift the wastewater to the integrated water purifier. The effluent from the fast filter pool enters into the intermediate pool, and the wastewater is lifted to the integrated water purifier by the intermediate lifting pump, and the flocculant is added through the pipeline mixer during the lifting process. The wastewater is treated by coagulation, sedimentation and filtration in the integrated water purifier, and the effluent enters into the outlet pool of the purifier, and the wastewater in the outlet pool of the purifier is lifted to the activated carbon rotary lift by the filter lifting pump. The wastewater in the water purifier outlet pool is lifted to the activated carbon spin-up filter by the lifting pump, and the water produced after the activated carbon filtration can reach the water output index by adding chlorine through the folding point, and then it enters into the clear water pool for reuse in the mining area or direct discharge. The sludge generated from the above process enters the sludge buffer tank and is lifted to the sludge thickener by the sludge pump. After the sludge is thickened by the sludge thickener, the supernatant returns to the regulating tank, and the sinking sludge is transported to the plate-and-frame filter press through the screw pump to carry out the sludge-water separation, and the separated filtrate returns to the regulating tank, and the sludge cake is transported out on a regular basis.

3.3 The main process and equipment analysis design processing capacity of 500m3/h, the system 24h continuous operation.

1) Conditioning tank. A submersible mixing system is set up in the regulating pool to prevent suspended matter from settling in the regulating pool. The regulating pool is designed as follows: effective volume, 1250m3; quantity, 2 seats; material, steel concrete; form, underground type. The main equipment is submersible mixer: model, QJB100-615; power, 10kW; quantity, 4 sets. Regulating pool lifting pump: model, 150WQ150-16-11; flow rate, 150m3/h; power, 11kW; head, 16m; quantity, 4 sets.

(2) Cyclone coagulator. Cyclone coagulator main equipment pipeline mixer: model, take over the calibre DN200; quantity, 4 sets. Cyclone coagulator: model, Ф3 200mm; maximum water treatment capacity, 150m3/h; quantity, 4 sets. Dosing system, 1 set. Dosing metering pump: model, GM0120; power, 0.25kW; quantity, 4 sets.

(3) Horizontal pipe sedimentation tank. Horizontal pipe sedimentation tank: quantity, 2; material, steel concrete; form, semi-underground type. Horizontal pipe sedimentation device: 2 sets. Horizontal pipe sedimentation device: 2 sets. Horizontal pipe cleaning trolley: 2 sets. 4) Bio-quick filtration tank. Bio-rapid filter: quantity, 2; material, steel concrete; form, semi-underground. Bio-filter filter material: 2 batches. Filter tank aeration system: 2 sets. Filter pool water distribution system: 2 sets. Filter tank aeration fan: air volume, 7.12m3/min; power, 11kW; quantity, 4 sets. Filter backwash pump: model, 200WQ400-18-37; flow rate, 400m3/h; power, 37kW; head, 18m; quantity, 2 sets. 5) Intermediate pool. Intermediate pool: effective volume, 600m3; quantity: 1; material, steel concrete; form, underground. Intermediate pool lifting pump: model, 200WQ270-14-15; flow rate, 270m3/h; power, 14kW; head, 15m; quantity, 3 sets.

(6) Full hydraulic control integrated water purifier. The use of LWJS-250 type full hydraulic self-control integrated water purifier, net size: Ф9400mm × 6200mm; Material: carbon steel; Number: 2 sets. Equipment room and control room: material, steel structure; form, ground type; quantity, 1 seat. Dispensing tank: net size, Ф1200mm×900mm; material, carbon steel; quantity, 4 sets. Dosing mixer model: BLD0.75-15-59Q; power, 0.75kW; quantity, 4 sets. Dosing metering pump: model, GM0170; power, 0.75kW; quantity, 4 sets. Pipeline mixer: Model, SF-250; Quantity, 2 sets.

7) Water purifier outlet tank. It is used to store the effluent of integrated water purifier. A certain amount of sodium hypochlorite is added to the water through the folding point chlorination method, and through a certain residence time, the sodium hypochlorite and the effluent water are fully mixed and reacted, so that the purpose of reducing the total nitrogen in the water is achieved. Water purifier outlet pool: effective volume, 600m3; quantity, 1; material, steel concrete; form, underground. Filter lifting pump: Model, 200WQ270-28-37; Flow rate, 270m3/h; Power, 37kW; Lift, 28m; Quantity, 3 sets (two for one standby).

(8) Clear water pool. After the activated carbon spin-up filter treatment of produced water, a certain amount of sodium hypochlorite is injected into the water through the folding point chlorination method, and through a certain retention time, so that the sodium hypochlorite and the effluent water are fully mixed and reacted, and the purpose of reducing the total nitrogen in the water is achieved, and it enters into the clearing basin for reuse in the mining area or direct discharge. Clear water pool: effective volume, 600m3; quantity, 1; material, steel concrete; form, underground type. Sodium hypochlorite generator: effective chlorine yield: 300g/h; quantity: 1 set.

(9) Sludge buffer tank. The mud-water mixture discharged from the cyclone desander and integrated water purifier firstly enters into the sludge pool buffer to homogenise the sludge water, and two submersible mixers are set up in the sludge buffer pool in order to prevent the sludge water from settling in the buffer pool. Sludge buffer tank: effective volume, 200m3; material, steel concrete; form, underground; number, 1. Buffer pool lifting pump: model, 100WQ80-25-11; flow rate, 80m3/h; head, 25m; power, 11kW; quantity, 2 sets. Buffer pool mixer: model, QJB022-320; power, 2.2kW; quantity, 2 sets. 10) Sludge thickener. It is used to thicken the sludge discharged from cyclone desander and integrated water purifier, which is more conducive to the operation of subsequent sludge treatment system. Sludge thickener: Model: Ф2 800mm; Quantity, 1 set. Screw pump: model, G40-1; flow, 12m3/h; head, 60m; power, 4kW; quantity, 2 sets.

4 Analysis of the operational effects of the project

4.1 Operation effect of Ximing mine mine water treatment upgrading and renovation project was completed in October 2020, after the renovation of the mine water treatment system can reach a capacity of 10,000m3 / d, the effluent water quality to meet the "surface water quality standards" in the class III water quality standards.

4.2 Running cost analysis of electricity: the total installed capacity of 400kWh, the actual operating capacity of 245kWh, equivalent to tonnes of water power consumption of 0.49kW - h. Electricity at 0.60 yuan / kW - h, then the electricity cost of 0.294 yuan / t. Labour costs: according to the three-shift shift, each shift according to the two on duty to consider, and another shift commander, a total of seven people, according to each person's monthly salary of 3500 yuan, a total of 24,500 yuan / month. 24500 yuan/month, equivalent to 0.068 yuan per tonne of water. Pharmacy fee: need to add coagulant (polymerisation of aluminium chloride), dosage of 5g/m3, polymerisation of aluminium chloride according to 2,000 yuan / t, then 0.01 yuan / t (water); coagulant (polyacrylamide) dosage of 2g / m3, polyacrylamide according to 7,000 yuan / t, then 0.014 yuan / t (water). The total pharmaceutical cost is 0.024 yuan/t (water). Therefore, the total operating cost is 0.294 + 0.068 + 0.024 = 0.386 yuan / t (water).

5 Conclusion In order to better treat mine water in Ximing Mine, Ximing Mine has carried out capacity expansion and upgrading transformation of the existing mine water treatment system. The expansion and upgrading of the idea of safeguard analysis, from the principle of selection of process solutions, treatment processes and procedures, the main process and equipment, etc., the expansion and upgrading of the transformation programme is described. After the transformation, the mine water treatment capacity has been effectively improved, and the operating cost of mine water treatment is only 0.386 yuan/tonne of water, which has better social and economic benefits.

Author: Prof Zhao Shujuan

Welcome to call us for consultation, technical exchange, and material experiment.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses