introductory

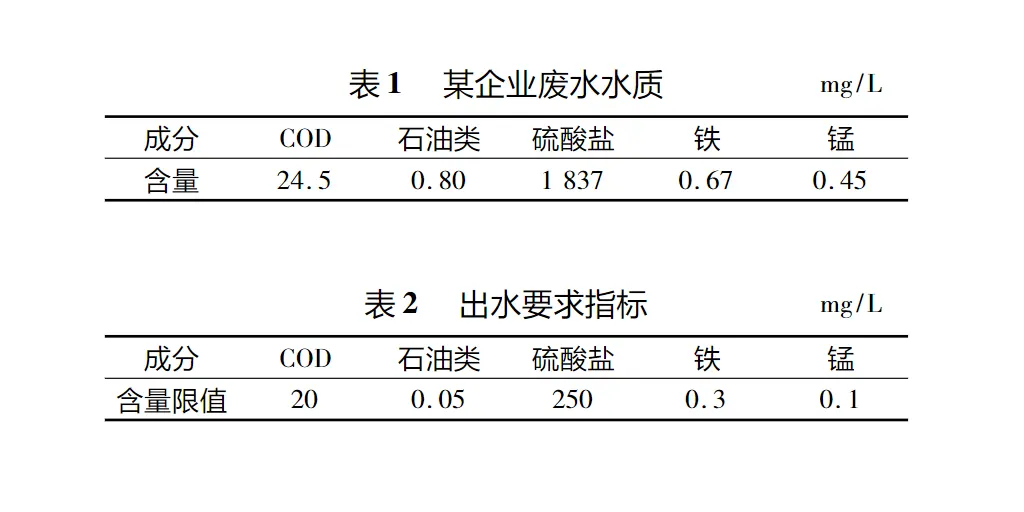

Some of the wastewater produced in the production process of an enterprise is discharged into the surrounding water bodies, and the local environmental protection department has found that sulphate exceeding the standard is more serious, which has changed the original ecological function of the surrounding water bodies. People drinking the surrounding water bodies occasionally diarrhoea phenomenon, contaminated water bodies will also cause the local workshop produced by the tofu quality decline, affecting the surrounding environment, agricultural production and residential life. Therefore, the elimination of excessive sulphate in the water body to protect the environment and human and animal safety is of positive significance.1 Wastewater indicators of the sulphate wastewater volume of 4500m3 / d, pH 7.7, alkaline, wastewater quality is shown in Table 1.

According to the requirements of the local environmental protection department, the pH of treated wastewater should be controlled from 6 to 9, and meet the requirements of the indexes of Class III water body of "Environmental Quality Standard for Surface Water" (GB3838-2002), see Table 2.

2 Conventional treatment methods

At present, the main treatment methods commonly used for sulphate wastewater are chemical precipitation method, physical-chemical method and biochemical method. (1) Chemical precipitation method, including barium salt precipitation method, calcium salt precipitation method, calcium alumina precipitation method, etc., mainly using barium ions, calcium ions, etc. and sulfate combined with the solubility of the product difference to remove sulfate. (2) Physical and chemical method, is the current industrial wastewater treatment technology commonly used methods, mainly the use of membrane separation technology to achieve the removal of impurities, including nanofiltration and reverse osmosis. The principle is to use different ions with different particle sizes to pass through man-made membranes with different pore sizes to carry out physical filtration under appropriate conditions. The advantage of membrane separation technology is that the treatment effect is good, the disadvantage is that the water quality of the water inlet side of the higher requirements, generally need pretreatment, one-time investment and operating costs are high, but also produce concentrated liquid, increasing the difficulty of subsequent treatment. (3) biochemical method, is the use of sulfate bacteria metabolism will be converted to sulfide sulfide. Sulphide can be converted into simple sulphur either by metal sulphide precipitation or by micro-oxygen metabolism of sulphur bacteria. The technology can be used for the treatment of inorganic and organic sulphate industrial wastewater.

3 Treatment process design

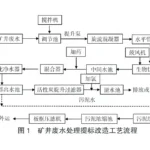

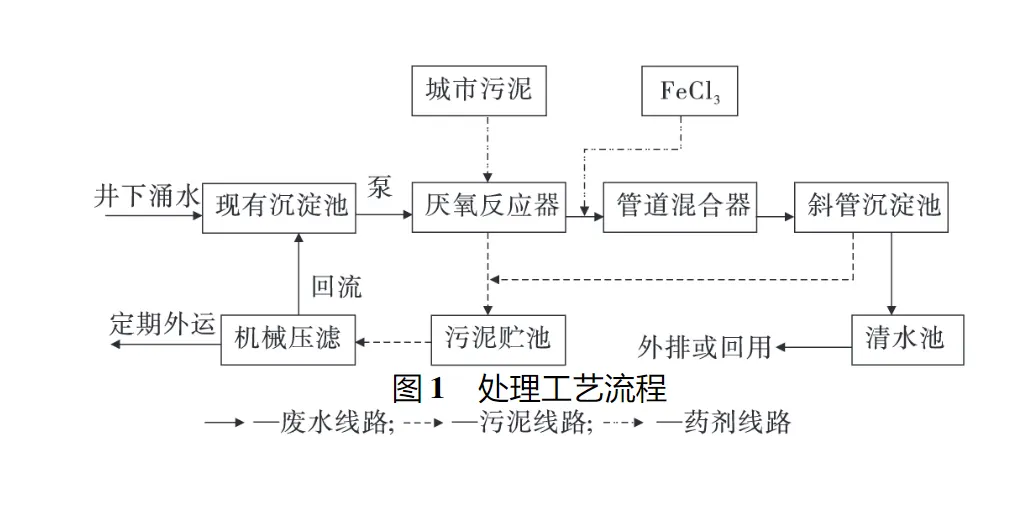

3.1 Process design Comparing the above three commonly used sulphate wastewater treatment methods and their advantages and disadvantages, according to the characteristics of the enterprise and the surrounding environment, the treatment process design is based on anaerobic treatment technology. The designed treatment process is shown in Fig. 1. The wastewater is lifted into the existing sedimentation tank, and then lifted to the anaerobic reactor (UASB) by a lifting pump to provide carbon source for the wastewater by adding municipal sludge to make the COD/SO2-4 value over 1. The UASB is designed to meet the advantageous environment of SRB bacteria. To satisfy the advantageous environment of SRB bacteria, the sulphate in the wastewater will be converted into hydrogen sulphide, and the toxic gas will be separated and collected and discharged through the three-phase separator in the anaerobic reactor. The effluent of the anaerobic reactor is fed with the pharmaceutical agent ferric chloride into the pipeline mixer, which further converts sulphur ions in the wastewater into metal sediments, and the pipeline mixing will enter into the inclined tube sedimentation tank to remove the metal sulphide precipitation formed. After precipitation, the wastewater flows into the existing clean water tank for reuse or external discharge. The bottom sludge in the UASB and inclined pipe sedimentation tank in the system flows into the sludge storage tank, which is briefly stored and then lifted to the mechanical filter press by the sludge lifting pump, after which the sludge is solidified and regularly transported out, and can be disposed of in a unified manner with the tailings of the plant, and the filtrate produced in the filter press process is returned to the existing sedimentation tank.

3.2 Design and selection of structures and equipment (1) lifting pumps, the existing sedimentation tank in the wastewater lifting to the anaerobic reactor. Select IS type axial suction single-stage centrifugal pump, model IS200-150-200, flow rate Q = 190m3/h, height H = 12.5m, power N = 8.55kW, choose 2 units, one with a backup. (2) Anaerobic reactor (UASB), anaerobic reaction of wastewater, through the artificial addition of carbon sources to increase the COD/SO2-4 value of wastewater, to promote the growth and reproduction of the SRB bacteria, the wastewater in the conversion of sulfate to hydrogen sulfide. Above ground type, size 20.0m×15.0m×5.3m, effective water depth 5.0m, total effective capacity 1500m3, surface load 0.625, total hydraulic retention time 8h. Equipment has stainless steel material up and down two sets of three-phase separator, supporting the inlet and outlet water and sludge discharge, exhaust piping, steel corrosion-resistant material. (3) pipe mixer, FeCl3 and wastewater for full mixing, reaction, to facilitate the formation of S2- metal precipitation. Choose GH type pipe mixer, model GH-250, carbon steel lined with rubber material, 1 unit. Equipment including pipe pump, used to pressurise the UASB water pressure. In order to make the water through the pipeline mixer can meet the flow rate and pressure requirements, choose SG-type pipeline pump, model 200SG200-20, flow rate Q = 200m3 / h, height H = 20m, power N = 18.5kW, choose 1; FeCl3 configuration system, used to configure the FeCl3 solution to be added to the pipeline mixer dosing port, mixing fully to form the metal sulphide precipitation. Choose integrated configuration equipment, model JY-II, machine power 1.5kW, choose 1. (4) Inclined pipe sedimentation tank, the formed metal sulphide will be precipitated to remove S2- and Fe3+ ions in the waste water. Above ground type, size 12.0m×12.0m×4.0m, effective volume about 245m3, super high 0.3m, effective water depth 1.7m, buffer layer height 0.5m, sludge hopper height 1.5m, sludge hopper volume about 80m3. Adopting honeycomb inclined pipe filler, height 1.0m, full-ground arrangement, 1 set. (5) Sludge storage tank, temporary storage of bottom sludge in UASB and inclined pipe sedimentation tank, regularly transported to filter press equipment. Semi-underground type, size 8.0m×3.5m, effective height 3.0m, effective volume about 150m3. The equipment has sludge lifting pump, used for lifting the sludge to the filter press, model G35-1, flow rate Q=8m3/h, height H=60m, power N=3.0kW, choose two sets, one with a spare; filter press, the sludge in the sludge storage tank is mechanically pressed and dewatered to form filter. Filter press, for the sludge in the sewage sludge storage tank to form filter cake by mechanical filter press and dewatering, choose belt filter press, model FDNY500, wet sludge processing capacity of 5-10m3/h, power 1.3kW, equipment size of 3.75m × 1.05m × 1.95m, choose 2 sets, one for one; filter press rinse pump, choose IS type axial suction single-stage centrifugal pump, model IS50-32-200, flow rate Q = 7.5m3/h, height H = 60m, power N = 3.0kW, choose 2 sets, one for one. 5m3/h, height H=52.5m, power N=2.82kW, choose 2 sets, one with a backup. (6) equipment plant, placing pharmaceutical dosing equipment, filter presses and ancillary equipment, etc., size 6.0m × 4.5m × 4.5m; built-in structures have filter press rinsing pool, size 1.5m × 1.5m × 1.5m, semi-subterranean structure, indoor depth of 1.0m below the ground level, the water from the existing lifting pumps connected to all the way to DN50 pipeline into the. (7) 1 power distribution room, above ground, size 6.0m × 4.5m × 4.5m; duty lounge 1, above ground, size 3.6m × 3.6m × 3.0m; rinse pool 1, above ground, size 1.5m × 1.5m × 1.5m.

3.3 application effect of sulphate wastewater treatment process route estimated engineering investment direct cost of about 5 million yuan, wastewater treatment cost of about 1.4 yuan / t (excluding depreciation). Using a small test simulation process route, in the influent flow 500L / h simulation, debugging 15d after continuous operation of 12h, respectively, take 3, 7, 12h effluent water samples for testing. Combined with the pollutant discharge limits in Table 2, the small-scale simulation test water indicators to meet the discharge requirements.

4 Conclusion (1) The process design focuses on the removal of sulphate in wastewater. Small simulation test effluent indicators show that the sulphate wastewater treatment process effluent can meet the water quality requirements of the pollution factors. (2) Small-scale simulation test commissioning time is relatively long, because the outdoor temperature is low in winter, adding the city sludge for the sewage treatment plant dewatering sludge, need to be fully dispersed; operation of the first few hours of the effluent water quality is relatively poor, the COD content is even more than 20mg / L, the reason is that the biochemical reaction time is shorter, the wastewater in the sludge content of the relatively small. (3) The treatment process uses less water and has a better treatment effect, which can provide guidance for subsequent medium-sized or on-site industrial tests and commissioning.

Welcome to call us for consultation, technical exchange, and material experiment.

Enquiry: 188517-18517

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses