Filter press is a commonly used solid-liquid separation equipment in industrial production, which is widely used in chemical, pharmaceutical, food, environmental protection and other fields. In the face of a wide variety of filter presses on the market, how to choose the right equipment for your production needs? This article will provide you with detailed answers from the following aspects.

I. Understanding the types and characteristics of filter presses

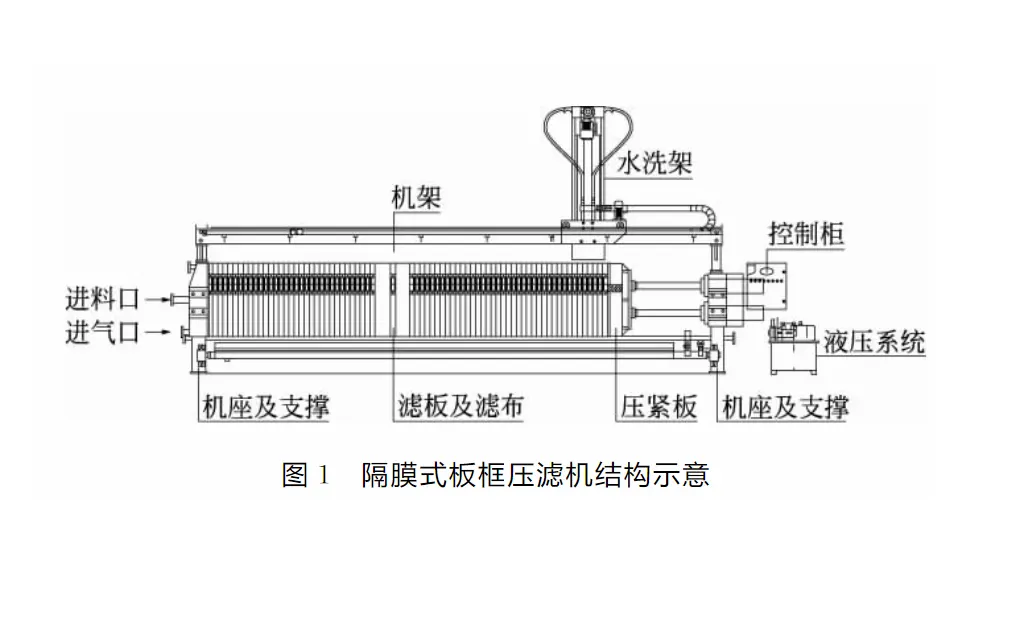

Filter presses are mainly divided into plate and frame filter presses and chamber filter presses, which are slightly different in structure and working principle. Plate and frame filter press has the advantages of simple structure, convenient operation and large filtering area, but it is troublesome to replace the filter cloth. Chamber filter press has the advantages of beautiful shape, good sealing, operation automation, but the price is relatively high. Understanding the characteristics and usage scenarios of various filter presses will help you better choose the right equipment for you.

Second, according to the production needs to choose the appropriate specifications and models

When choosing a filter press, you need to consider your production scale, material characteristics, filtration precision and other factors. For example, for materials with large processing capacity and small solid particles, you need to choose filter presses with large filtration area and small filtration aperture; while for materials with small processing capacity and large solid particles, you can choose equipment with larger filtration aperture. It is also necessary to consider the degree of automation of the equipment, maintenance costs and other factors.

Third, pay attention to the performance parameters of the filter press

When choosing a filter press, you need to pay attention to its performance parameters, such as working pressure, filtration speed, water content of the filter cake and so on. Generally speaking, the higher the working pressure, the better the separation effect of the equipment, but at the same time, the higher the material and structure requirements of the equipment. The faster the filtration speed, the higher the productivity of the equipment, but may affect the separation effect. The lower the water content of the filter cake, the better the dewatering effect of the equipment. It is necessary to choose the appropriate performance parameters according to the actual production requirements and material characteristics.

IV. Understanding suppliers' after-sales service and support

When choosing a filter press, you also need to consider the supplier's after-sales service and support. A good supplier should be able to provide perfect after-sales service, including equipment installation and commissioning, operation training, maintenance and other services. When problems are encountered during the use of the equipment, the supplier should be able to provide technical support and solutions in a timely manner. Therefore, it is very important to choose a supplier with good after-sales service and reputation.

V. Case studies and sharing of practical experience

In order to help you better understand how to choose a suitable filter press, this article will analyse and share experience with practical cases. The following are two typical cases:

Case 1: A chemical enterprise needs to treat a large amount of industrial wastewater and requires a filter press with high filtration precision and separation effect. After comparison and analysis, the enterprise chose the plate and frame filter press, and chose the model with larger filtration area and higher working pressure. The equipment performs well in actual operation and meets the production needs of the enterprise.

Case 2: A food enterprise needs to deal with impurities such as pulp and fibre in fruit and vegetable juice drinks, and requires a filter press with high filtration speed and automation. After investigation and evaluation, the enterprise chose a chamber filter press, and selected a model with a smaller filter aperture and a higher filtration speed. The enterprise also chose equipment with an automated control system and remote monitoring functions to reduce labour costs and improve production efficiency. The equipment has performed stably and reliably in actual operation, bringing good economic benefits to the enterprise.

Through the analysis of the above two cases and practical experience sharing, we can see that different enterprises have different needs for filter presses, which need to be selected according to their actual situation. Also need to pay attention to the performance parameters of the equipment, after-sales service and support, etc., in order to ensure the stable operation of the equipment and the smooth progress of production.

Choosing the right filter press requires consideration of the combined effects of several factors. It is recommended that companies follow the following suggestions when choosing a filter press:

1. Selection and matching of specifications according to actual production requirements;

2. Concern about the performance parameters of the equipment and the supplier's after-sales service and support;

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses