Filter press mesh belt is an important part of filter press equipment, mainly used for filtration and dewatering. This article will introduce in detail the basic concept, types, materials, production process, performance indexes and application areas of filter press mesh belt.

I. Basic concepts

Filter press mesh belt, also known as filter press cloth, is a kind of filter medium made of fibre material, which is mainly used for solid-liquid separation and liquid filtration. During the working process of a filter press, the filter press mesh belt is placed in the filter chamber of the filter press, and the liquid is squeezed out of the mesh belt by applying pressure, thus realising the purpose of solid-liquid separation and liquid filtration.

II. Types

1. Classification according to material: filter press mesh belt can be divided into synthetic fibre mesh belt and natural fibre mesh belt according to material. Synthetic fibre mesh belt is usually made of polyester fibre, polypropylene fibre and other synthetic fibres, with high acid and alkali resistance and high temperature resistance; natural fibre mesh belt is made of natural fibres such as cotton, hemp, etc., which is relatively low in price, but poor in acid and alkali resistance and high temperature resistance.

2. Classification according to weaving method: filter press mesh belt can be divided into woven type, non-woven type and composite type according to weaving method. Woven mesh belt is woven by loom, with high strength and wear resistance; non-woven mesh belt is made of short fibres stacked in a disorderly manner, with large pores and good air permeability; composite mesh belt is compounded with two or more kinds of materials to obtain better filtration performance and durability.

3. Classification according to shape: Filter press mesh belt can be divided into round mesh belt and shaped mesh belt according to its shape. Circular mesh belts are round or nearly round in shape, applicable to regular filter press equipment; irregular mesh belts are triangular, rhombus and other irregular shapes, applicable to special filtration needs.

III. Material

The material of filter press mesh belt mainly depends on its usage environment and filtration requirements. Common materials include synthetic fibres such as polyester, polypropylene and polyamide fibres, as well as natural fibres such as cotton and hemp. In order to improve the durability and filtration performance of the mesh belt, some manufacturers also apply special coatings on the mesh belt, such as silica gel, fluorine resin and so on.

IV. Production process

The production process of filter press mesh belt mainly includes two stages: weaving and post-treatment. The weaving stage is mainly to weave the fibre material into a mesh structure according to a certain organisational structure; the post-treatment stage is to heat-setting, dyeing, coating and other treatments for the woven mesh belt to improve its performance and appearance quality.

V. Performance indicators

The performance indexes of filter press mesh belt mainly include air permeability, filtration, strength, abrasion resistance, acid and alkali resistance, high temperature resistance and so on. Among them, air permeability and filtration are important indicators of the performance of the mesh belt, which directly affect the filtration effect and service life of the filter press; strength and abrasion resistance determine the service life and reliability of the mesh belt; acid and alkali resistance and high temperature resistance are applicable to the filtration needs in different environments.

VI. Areas of application

Filter press mesh belt is widely used in chemical, environmental protection, food, pharmaceutical and other fields. In the field of chemical industry, filter press mesh belt is mainly used for solid-liquid separation and liquid filtration during various chemical reactions; in the field of environmental protection, it is mainly used for sewage treatment and sludge dewatering; in the field of food, it is mainly used for the filtration and clarification of liquids such as beverages, wines, dairy products, and so on; and in the field of pharmaceuticals, it is mainly used for filtration and separation of medicinal liquids.

Filter press mesh belt is an important part of filter press equipment, with a wide range of applications and important functional role. This article introduces in detail the basic concept of filter press mesh belt, types, materials, production process, performance indicators and application areas and other aspects of knowledge. It is hoped that it can help readers better understand the basic concepts and characteristics of filter press mesh belt, and also provide a certain reference value for technicians in related industries.

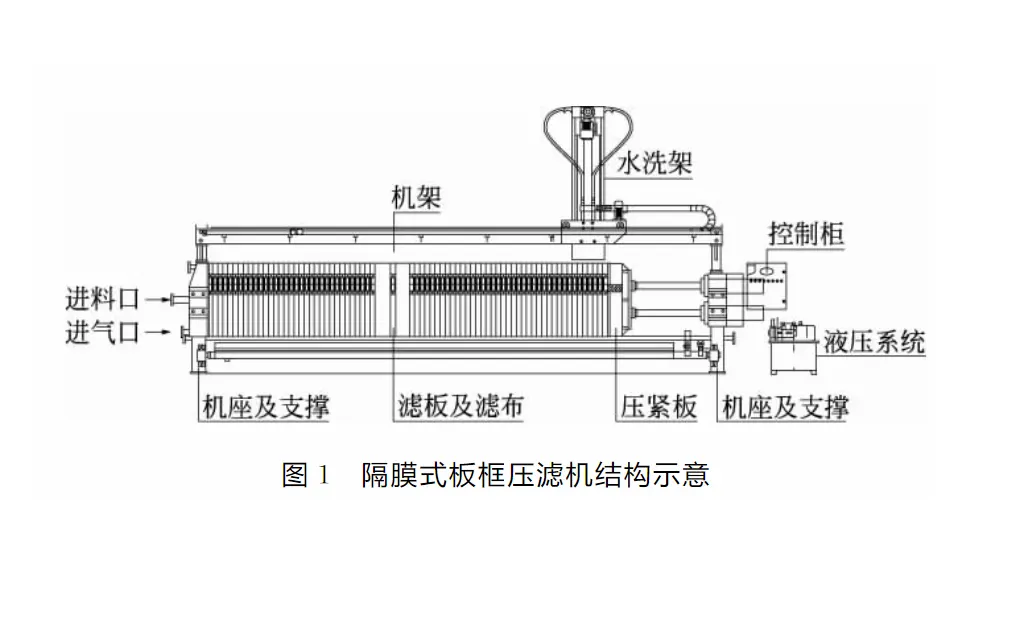

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses