As a kind of solid-liquid separation equipment widely used in environmental protection, chemical, food and other industries, the stable and efficient performance of the filter press is crucial to the smooth running of production. As an important part of the daily maintenance of the filter press, backwashing can effectively prevent the filter cloth from clogging and improve the efficiency of the equipment. In this article, we will analyse the backwashing principle, operation method and precautions of the filter press in detail.

I. Principle of backwashing

The backwashing of the filter press is to restore the filtering function of the filter cloth by reversing the pressure to the side of the filtered material, so that the material is flushed down from the surface of the filter cloth in the reverse direction, in order to remove the residual cake or clogging on the surface of the filter cloth, and thus restore the filtering function of the filter cloth. In the process of backwashing, it is necessary to control the pressure and flow rate of the backwashing water, so that it can fully flush out the clogging material on the surface of the filter cloth, and at the same time, avoid excessive wear and tear or impact on the filter cloth.

Second, backwash operation method

1. Switch off the feed and discharge pumps to stop material filtration.

2. Open the backwash water valve and inject a certain pressure of backwash water into the filter press.

3. Observe backwash water flow and pressure gauges and adjust valve openings to control backwash water flow and pressure.

4. Observe the surface of the filter cloth and close the backwash water valve when any residue is found to have been washed down.

5. Switch on the feed and discharge pumps and restart material filtration.

C. Backwashing Precautions

1. Backwash water pressure and flow should be moderate, not too large or too small. Too big will cause impact wear and tear on the filter cloth, too small will not be able to fully flush out the blockage.

2. The backwashing operation needs to be carried out after the pressure of the filter press is completely removed to avoid damaging the internal structure of the filter press and the filter cloth.

3. In the backwashing process, pay attention to observe the scouring of the residue on the surface of the filter cloth, and adjust the backwashing water flow and pressure in time.

4. Regularly check the integrity of the filter cloth and replace or clean it in a timely manner if it is damaged or seriously clogged.

5. In some cases, it may be necessary to use chemical cleaning agents for cleaning. When using chemical cleaning agents, follow the instructions for use and ensure that the cleaning agent does not cause corrosion or damage to the filter cloth and internal structure of the filter press.

6. Keep the environment around the filter press clean and hygienic to avoid debris and dirt from entering the inside of the filter press and affecting the backwashing effect and normal operation of the equipment.

7. For filter presses working continuously, backwashing should be carried out periodically to ensure the continued efficient operation of the equipment. Depending on the actual situation, a fixed time interval for backwashing can be set or judgement can be made according to the condition of the residue on the surface of the filter cloth.

8. Train operators to correctly master the operation methods and precautions of backwashing to avoid damage to the equipment or affecting the filtration effect due to improper operation.

9. For large or special filter press equipment, special backwashing equipment and tools may be required. Before backwashing the equipment, the operating instructions and relevant operating procedures should be understood in detail and the equipment manufacturer's recommendations should be followed.

10. Establish a sound equipment maintenance system, with backwashing as one of its important elements. Record and statistically analyse the time, flow rate, pressure and other parameters of each backwash so that potential problems can be identified and dealt with in a timely manner.

The filtration efficiency and service life of the filter press can be effectively improved through an in-depth understanding and mastery of the backwashing principle, operation methods and precautions of the filter press. In actual production, according to different models and specifications of the filter press and different application scenarios, the corresponding backwashing programme and maintenance plan should be developed. Strengthen the daily inspection and maintenance of the equipment to ensure that the filter press is always in good working condition, contributing to the stable production and environmental protection.

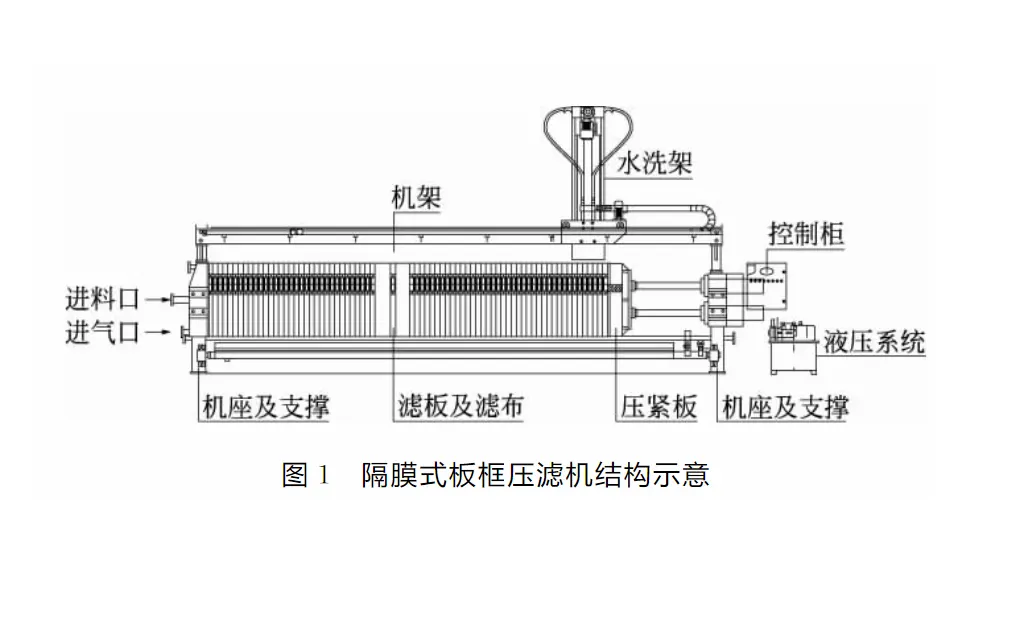

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses