Filter press as an important equipment in industrial production, its normal operation has an important impact on production efficiency and product quality. The hydraulic oil, as an important medium in the filter press, plays a vital role in the performance and service life of the equipment. In this article, we will discuss in depth the problems that may be caused by not changing the hydraulic oil of the filter press, in order to help readers better understand this field.

I. The role and importance of hydraulic oil

Hydraulic oil plays the role of transmitting pressure, lubrication, cooling and rust prevention in the filter press. Hydraulic oil transmits the pressure to the various components of the filter press through the hydraulic system, driving the normal operation of the equipment. Hydraulic oil also plays the role of lubrication, reducing friction and wear between parts and extending the service life of the equipment. Hydraulic oil can also take away part of the heat in the circulation process, play a cooling effect. High-quality hydraulic oil can also prevent equipment rust and corrosion, to protect the equipment from environmental factors.

II. Potential problems of not changing the hydraulic fluid

1. Oxidation and contamination: Hydraulic fluids used over a long period of time are subject to oxidation and deterioration due to high temperatures, oxygen and metal particles. This leads to an increase in viscosity, acidity and corrosiveness of the hydraulic fluid, which adversely affects the equipment. As contaminants accumulate, the filtration and fluidity of the hydraulic fluid decreases, further exacerbating equipment wear and failure.

2. Wear and clogging: Contaminants and impurities in the hydraulic fluid can adhere to the inside of the hydraulic system, causing wear and clogging of components. This may lead to unstable pressure and insufficient flow in the hydraulic system, affecting the normal operation and service life of the equipment.

3. Decrease in cooling effect: Hydraulic oil carries away heat in the circulation process and plays a cooling role. If the hydraulic oil is not replaced, its cooling effect will gradually decrease, resulting in equipment overheating, accelerated wear and performance degradation.

4. Corrosion and rust: Hydraulic fluids used over a long period of time may contain corrosive substances that can cause corrosion of metal parts. Water and other impurities can also accumulate in the hydraulic fluid, leading to rust and corrosion of the equipment. This not only affects the appearance of the equipment, but may also cause safety problems.

5. Reduced efficiency: As hydraulic fluids deteriorate and become contaminated, the operational efficiency of equipment is affected. This can lead to problems such as reduced productivity, wasted energy and increased production costs.

6. Regulatory compliance and environmental issues: Some countries and regions have strict regulations regarding the disposal of industrial equipment oil. Failure to change hydraulic fluids on a regular basis can be a violation of these regulations, as well as a potential pollution risk to the environment.

III. Importance of hydraulic fluid replacement

In order to ensure the proper operation and longevity of the filter press, it is vital to change the hydraulic oil regularly. By changing the hydraulic oil regularly, the accumulation of oxidation and contaminants can be reduced, wear and clogging can be prevented, and the stability and reliability of the hydraulic system can be maintained. The performance specifications of new hydraulic fluid can meet the requirements of equipment operation, providing better lubrication, cooling and rust prevention. Regular replacement of hydraulic fluid also helps to reduce maintenance and production costs and improve the economic efficiency of the enterprise.

Fourth, how to correctly replace the hydraulic oil

1. Selection of suitable hydraulic oil: Select the suitable hydraulic oil according to the model of filter press and the conditions of use, and ensure that it has excellent oxidation resistance, viscosity and lubricity and other performance indicators.

2. Preparation of tools and materials: Prepare the necessary tools such as oil drums, filters, cleaners, etc., and fresh hydraulic fluid. Ensure that tools and materials are clean and free of contamination.

3. Shutdown and preparation: Prior to changing the hydraulic fluid, the filter press should be shut down and the pressure in the hydraulic system should be drained. The equipment and surroundings should be cleaned to ensure a smooth change process.

4. Drainage of Old Hydraulic Fluid: Open the drain port of the hydraulic tank and drain the old hydraulic fluid into a designated container. Be careful not to allow contaminants to enter the new oil drum.

5. Cleaning and inspection: Clean the components of the hydraulic system with detergent and appropriate tools and inspect for signs of wear or clogging. If necessary, repair or replace them promptly.

6. Add new hydraulic oil: Add new hydraulic oil to the hydraulic system and make sure the oil level is within the specified range. Close the discharge port of the hydraulic oil tank and start the filter press for testing and inspection.

7. Records and maintenance: Record information such as the time, type and quantity of hydraulic fluid changed for future maintenance and management. The instruction manual of the equipment should be followed for routine maintenance and repair to ensure the normal operation and service life of the equipment.

Filter press hydraulic oil change is important for the normal operation and service life of the equipment. By replacing the hydraulic oil regularly, problems such as oxidation, pollution and wear can be reduced, and the performance and stability of the equipment can be maintained. Enterprises should pay attention to the replacement and maintenance of hydraulic oil, formulate a reasonable maintenance plan and strictly implement it. They should choose the right hydraulic oil and follow the correct replacement process to ensure the normal operation of the equipment and the use of the effect. Through reasonable maintenance and management, the service life of the filter press can be extended, the maintenance cost can be reduced and the economic efficiency of the enterprise can be improved.

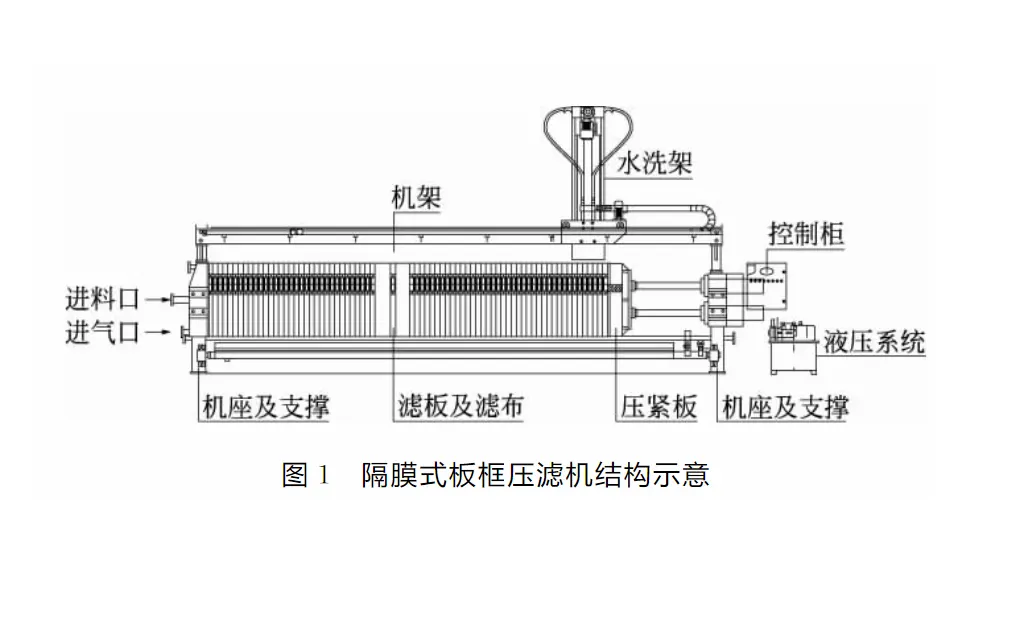

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses