As a widely used equipment in the field of solid-liquid separation, the working principle and structural design of the filter press are crucial for improving production efficiency and separation effect. In the structure of the filter press, the fixed end is an important component. This paper will discuss the role and advantages of the fixed end in the filter press, as well as its important position in the working process of the filter press.

I. Role of fixed ends in filter presses

1. Providing support and stability: The fixed end provides the necessary support for the filter press to ensure the stability of the equipment during operation. It effectively transfers the weight and load of the filter press to the ground through its connection with the foundation, preventing the equipment from being displaced or overturned during operation.

2. Restriction of plate movement: During the filtration process of a filter press, the plates need to remain in a relatively stable position. By restricting the movement of the filter plates, the fixed end ensures that the distance between each plate is consistent, so that the material can be evenly distributed in each filter chamber.

3. Withstand pressure: During the operation of the filter press, a certain amount of pressure needs to be applied to achieve solid-liquid separation. The fixed end bears part of the pressure and applies it uniformly to each plate and material through a pressure transfer mechanism, thus improving filtration.

4. Guiding and positioning: the fixed end provides guiding and positioning for the installation and removal of the filter plate. Through the guiding groove or positioning holes on the fixed end, the filter plate can be installed quickly and accurately, which reduces the difficulty of installation and improves the working efficiency.

II. Design and optimisation of the fixed end

1. Material selection: According to the use environment of the filter press and the characteristics of the materials to be processed, choose suitable materials to manufacture the fixed end. Commonly used materials include cast iron, steel, wear-resistant ceramics, etc. to ensure the strength, corrosion resistance and wear resistance of the fixed end.

2. Structural design: the structural design of the fixed end needs to meet the requirements of support, stability, pressure and other aspects. Through reasonable structural design, it can reduce the manufacturing cost and maintenance cost, and improve the overall performance and service life of the equipment.

3. Surface treatment: According to the actual needs, the fixed end is given appropriate surface treatment to improve its corrosion and wear resistance. Common surface treatment methods include spraying anti-corrosion coatings, carburising and quenching, chromium plating and so on.

4. Maintenance and upkeep: Regularly inspect and maintain the fixed end to ensure its normal operation. For parts with serious wear and tear, they should be repaired or replaced in time to avoid equipment failure and affecting productivity.

III. Advantages of fixed ends in filter presses

1. Improve the stability of the equipment: through the support of the fixed end, the filter press can remain stable during the working process, avoiding the filtering effect and production efficiency being affected by the shaking or displacement of the equipment.

2. Improve filtration efficiency: the restraining effect of the fixed end keeps the filter plate in a stable position, ensures the uniform distribution of materials, and improves the filtration efficiency and separation effect.

3. Reduced maintenance costs: Optimised design of the fixed end and reasonable surface treatment can reduce wear and corrosion, thus reducing the frequency of repair and replacement and lowering maintenance costs.

4. Improved work efficiency: the guiding and positioning function of the fixed end helps to install and remove the filter plate quickly and accurately, which improves work efficiency and productivity.

5. Adaptation to a variety of working conditions: the design of the fixed end can be customised and optimised according to different working conditions and use environments, in order to meet a variety of special needs and cope with complex working conditions.

IV. Case studies and application examples

In order to further illustrate the role and advantages of fixed ends in filter presses, this paper will be analysed with practical cases. A chemical company uses a fixed-end filter press for wastewater treatment. The fixed end of the filter press is well designed to withstand high pressure and provide stable support. During operation, the fixed end effectively restricts the movement of the filter plate, ensuring filtration and separation efficiency. Regular maintenance ensures the normal operation and service life of the fixed end. By using this filter press, the enterprise has improved the efficiency and quality of wastewater treatment and reduced production costs and environmental pollution.

The fixed end plays an important role in the filter press, playing multiple roles such as providing support, restricting the movement of the filter plate, and withstanding pressure. By optimising the design of the fixed end and using suitable materials, the stability, filtration efficiency and service life of the filter press can be improved. In practical application, attention should be paid to the maintenance and upkeep of the fixed end, and regular inspection and repair should be carried out to ensure its normal operation. Strengthen the training and management of operators and standardise the operation process to give full play to the role and advantages of the fixed end in the filter press. With the continuous progress and innovative development of technology, it is believed that the design of fixed end of filter press will be more advanced, reliable and cost-effective in the future.

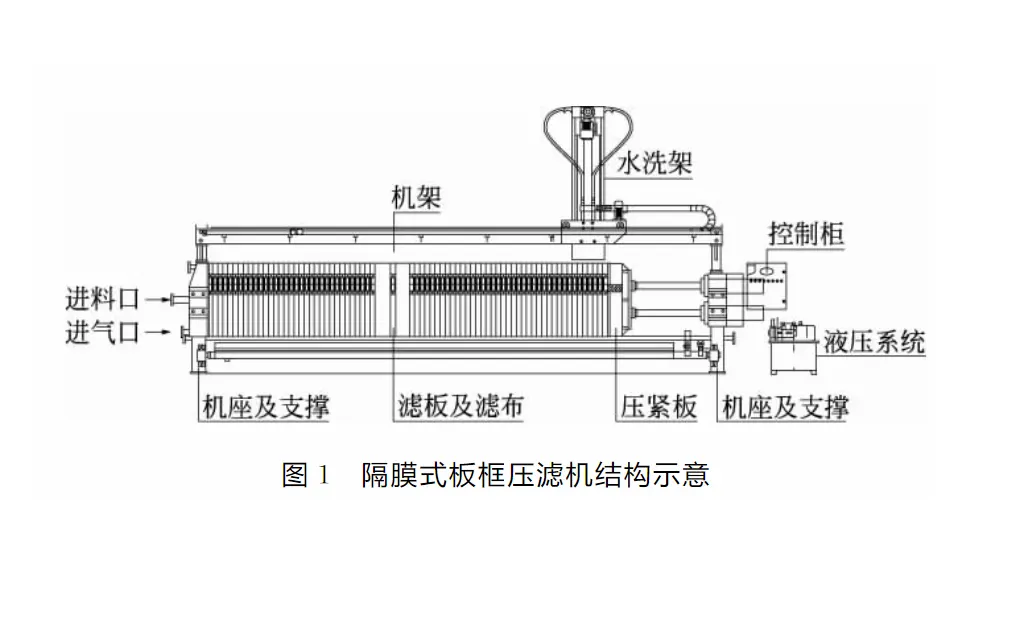

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses