Maintenance of automatic diaphragm filter press

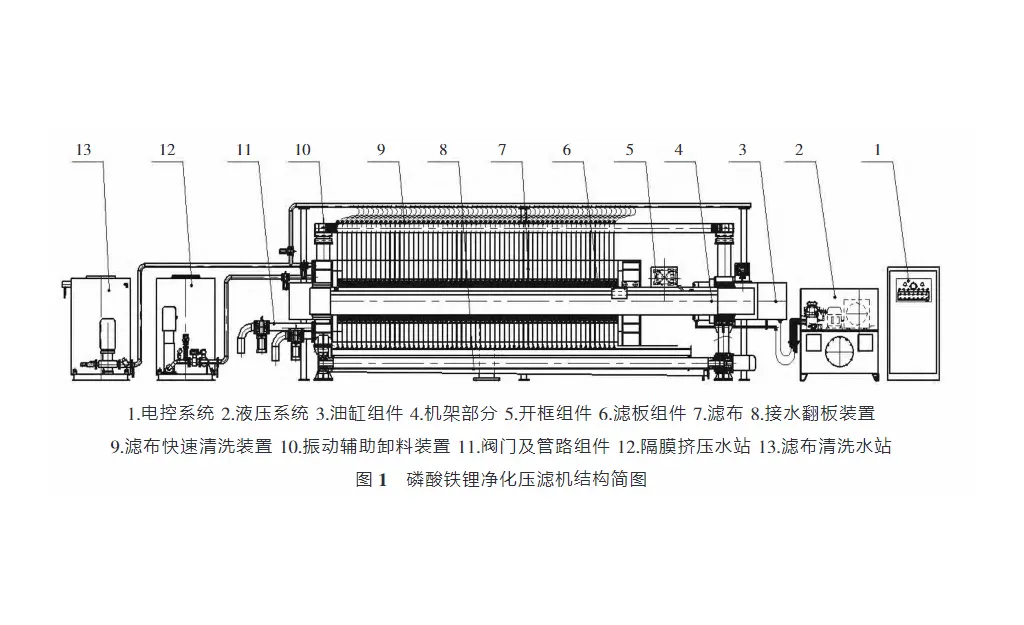

693Application of Automatic Diaphragm Filter PressAutomatic diaphragm filter press is a kind of intermittent filtration, washing and pressing equipment, which is applied to solid-liquid separation of various suspensions. It relies on the pressing device to press the filter plate to fix the filter cloth with sealing, and uses chemical pump to press the suspension into the filter chamber, and filters the solid-liquid materials through the filter cloth to separate them, and can also...

View full text Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses