introductory

With the improvement of coal mining and coal processing mechanisation, the amount of coal slurry has increased significantly, and the corresponding output of fine-grained coal processing products has also increased significantly. The increase in the content of fine coal slurry has increased the difficulty of coal slurry water treatment and coal slurry dewatering and recycling, and the realisation of solid-liquid separation.

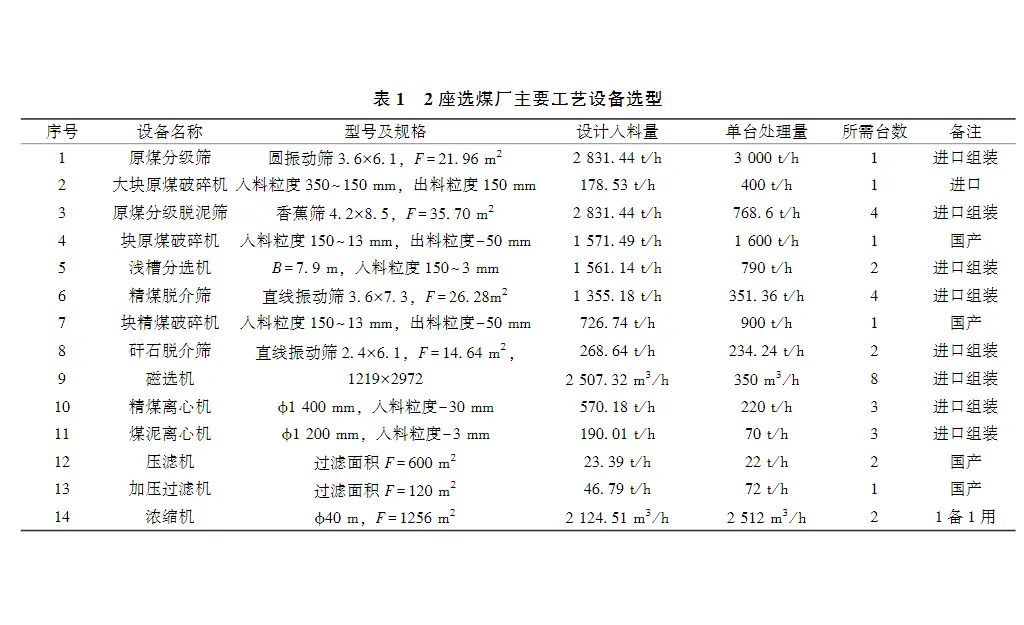

1 The application of plate and frame filter in the coal processing plant of Shendong mining area

As a kind of solid-liquid separation equipment, plate and frame filter press is mainly used for coal slurry dewatering and recycling and realising solid-liquid separation, which is widely used in coal processing plants. The main factors affecting the working effect of plate and frame filter press are closing pressure, squeezing pressure, holding time, feeding time and the nature of the feeding material (mainly the density of the material, particle size distribution, concentration, viscosity, settling speed and other characteristics). The hourly capacity of most plate and frame filter presses in the washing centre is 82.71 TP3T of the design capacity, with an average moisture failure rate of 8.51 TP3T.

2 Coal Mud Water Treatment System in Shi Ohtai Coal Processing Plant

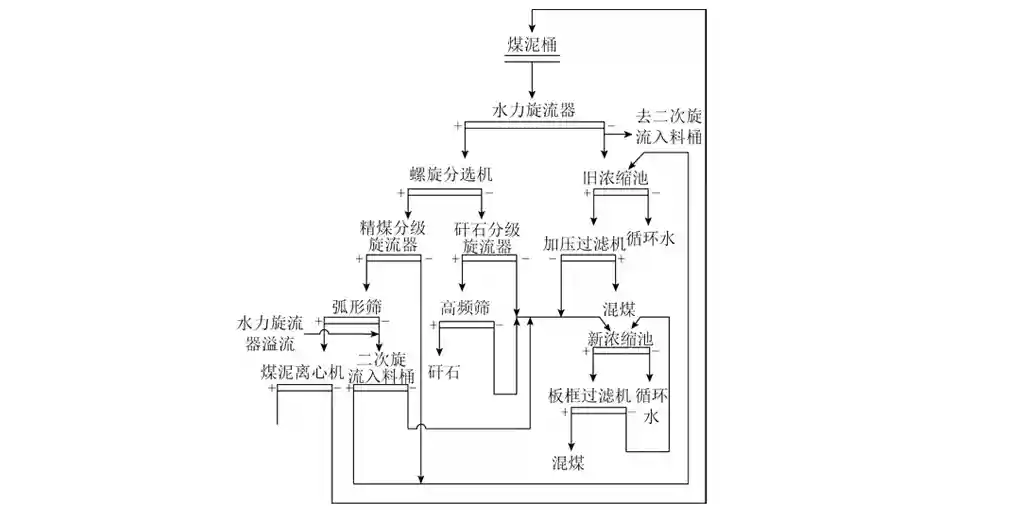

The plate and frame filter press of Shi Ohtai Coal Processing Plant mainly handles gangue cyclone overflow, secondary cyclone overflow, pressurised filter and plate and frame filter press filtrate, such as high ash and fine mud peat slurry water concentration underflow. The specific process flow is shown in Figure 1.

3.1 High moisture in fine coal slurry

The moisture of the product of plate and frame filter press of Shi Ohtai Coal Processing Plant reaches 33%, which is mainly due to the gangue of Shi Ohtai Coal Processing Plant is easy to sludge and the feed size of plate and frame filter press is too small.

3.1.1 Gangue susceptibility to fouling

Shi Ohtai coal processing plant gangue there is serious mud phenomenon, the use of sorting process for 3mm wet desliming, > 13mm shallow trough separator points, select 13 ~ 3mm using heavy media cyclone sorting, end coal concentrate and gangue desliming under the sieve dilute media mixing with magnetic separator recovery, magnetic separation tailings returned to the primary coal slurry barrel, resulting in a large number of gangue dilute media of high grey fine mud re-entry into the cycle of the coal slurry water system. This part of the gangue mud further sludge, into the concentration pool, in the process of filtering the formation of extremely difficult to settle and filtering gangue mud.

3.2.1 Too fine a granularity

Plate and frame filter press feeding size is too fine will not only affect the product moisture, but also reduce the processing capacity of plate and frame filter press. If the particle size is too fine, the coal slurry close to the filter cloth in the feeding process will form a cake quickly, and the moisture of the subsequent coal slurry can not be discharged, so it is difficult to form a cake, and when the feeding pressure reaches the set value, the inside of the cake still contains a lot of moisture. At this time there are two situations: ① directly into the next process, the amount of coal slurry in each chamber is small, affecting the processing capacity; ② feeding again, increase the amount of coal slurry in the filter chamber, the need to feed two or more times, reducing the plate and frame filter press processing capacity...

3.2.2 Inadequate routine maintenance

Plate and frame filter press daily operation and maintenance projects are more, including electrical, mechanical, hydraulic and other systems, the main problems are: filter cloth cleaning is not timely, resulting in the head and tail tilt, resulting in accidents and stops, and even damage to the equipment, while bringing potential safety hazards; job skills are uneven, there is misuse, resulting in damage to the equipment; maintenance personnel do not have enough mastery of the equipment, found that the problem can not be dealt with in a timely manner, increasing maintenance time, reducing the ability to deal with.

3.2.3 Unreasonable parameter settings

The plate and frame filter press is inconsistent with the working condition and design as the use time increases, and the working parameters are modified. Due to the change in the nature of coal slurry in the Ohtai Coal Processing Plant, the content of very fine coal slurry has increased significantly, the feeding characteristics of the plate and frame filter press have changed, and the set parameters can no longer be adapted to the current working conditions.

3.3 High amount of fine coal sludge

Existing plate and frame filter press processing capacity can not meet the requirements of fine coal slurry processing, and plate and frame filter press itself to reduce the processing capacity and coal preparation plant fine coal slurry amount increases closely related. Selection of 13 ~ 3mm using heavy media cyclone sorting, the end of the coal concentrate and gangue de-mediation under the screen dilute media mixed with magnetic separator recovery, magnetic separation tailings returned to the primary coal slurry barrel, resulting in a large number of gangue dilute medium of high ash fine mud into the coal slurry water system cycle again![3]This part of the gangue mud further sludging. This part of the gangue mud further sludge, into the concentration pool, in the filtering process to form extremely difficult to settle and filtering gangue mud.

3.1.2 Too small feed size

Plate and frame filter press mainly deals with fine coal slurry, but there are still certain requirements for the particle size of coal slurry, and the plate and frame filter press of Shi Ohtai Coal Processing Plant mainly deals with gangue cyclone overflow, secondary cyclone overflow, pressurised filter and plate and frame filter press filtrate, and the content of <0.045mm level reaches 77.85%, which results in the squeezing process, and the part of the cake near the plate is formed into a cake with very small cake void, and the internal moisture is difficult to be discharged, and the moisture in the product of plate and frame filter press is increased. Difficulty increases, and the moisture of the plate and frame filter press product rises.

- 2 Plate and frame filter presses with low processing capacity

The original processing capacity of the plate and frame filter press of the Ohtai Coal Processing Plant was 30t/h, but now it is only 20t/h, and the reasons for this are too fine a particle size, lack of routine maintenance and irrational parameter settings... Shi Ohtai Coal Selection Plant was designed with the amount of fine coal sludge of 90t/h, due to the change of coal quality, the amount of coal sludge increased, and the amount of fine coal sludge was 145t/h, an increase of 61.11%, which led to the plate and frame filter press processing capacity can not meet the requirements....

- 1 Working parameter aspects

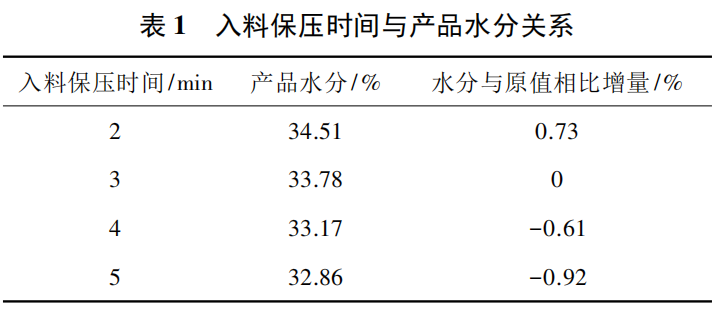

4.1.1 Holding time for feeding material

With other parameters unchanged, the feed holding time was adjusted and the results are shown in Table 1.The longer the feed holding time, the lower the moisture content of the product... The trend of moisture reduction slowed down when the holding time of the feed was more than 4 min.

4.1.2 Extrusion pressure

Adjust the extrusion pressure while other parameters remain unchanged. The higher the extrusion pressure the lower the moisture content of the product, and when it exceeds 700 kPa, the decreasing trend slows down.

4.1.3 Squeeze time

Adjust the extrusion time while other parameters remain unchanged. The longer the extrusion time the lower the product moisture, when more than 5min, the decreasing trend slows down.

4.2 Nature of feed

4.2.1 Concentration analysis

Optimisation test of feed mass concentration, before the test to predict the possible results, first of all, the feed time is reduced, but accompanied by a reduction in the amount of feed, the concentration increases too late to fill the filter chamber has become a cake, resulting in incomplete feeding, so the main consideration of the impact on the processing capacity of the plate and frame filter press.

The greater the concentration of feed, the greater the plate and frame filter press processing capacity, more than 350g/L, can not be realised at a time into the material, resulting in an increase in feeding time, plate and frame filter press overall processing capacity is reduced. Analysis of stone ohtai coal processing plant plate and frame filter press feed mainly: gangue cyclone overflow, secondary cyclone overflow, pressurised filters and plate and frame filter press filtrate through the thickener after settling the bottom stream, from the process to improve the feed concentration is more complex, so according to the thickener rake torque to determine the amount of slurry at the bottom of the pool, to determine the number of sets of opening the plate and frame filter press, to increase the concentration of the feed. The current of the motor reflects the size of the rake torque.

It can be analysed that the larger the proportion of coarse doping is, the lower the moisture of the product is, the lowest is reduced to 27.46%, which is 4.54% lower than the 32.00% before the transformation. it can be seen that the larger the proportion of coarse doping is, the shorter the feeding time is, the more water can be discharged through the gap in the process of feeding, to ensure that the amount of the slurry is fed in one time, and to reduce the number of times of feeding and the time of feeding, but with the increase of the proportion of coarse doping, the coarse particles in the slurry are more difficult to be formed into cakes. However, as the proportion of coarse mixing increases, the coarse particles in the coal slurry increase, the difficulty of cake formation increases, the unloading is difficult, the unloading time increases, especially when the proportion of coarse mixing reaches 100%, the labour intensity of the workers increases, and the danger increases.

Therefore, the analysis in terms of treatment capacity enhancement should be done by using a coarse doping ratio of 75%, i.e., the coarse doping pipeline opening should be maintained at 75%.

Use of filter aid. Under the condition of mixing coarse and optimal working parameters, adding a certain amount of filter aid to the feed of plate and frame filter press, the product moisture was reduced from 26.46% to 25.67%. Adding a certain amount of filter aid to the feed of plate and frame filter press can indeed reduce the product moisture, but with the increase in the amount of additive, i.e., the opening of the additive valve, the product moisture was reduced to a certain extent and then it was no longer significantly reduced. . Dosing pipeline valve opening 50% in the case of product moisture reached 25.73%, as the opening continues to increase, the product moisture from 25.73% down to 25.67%, a reduction of 0.06 percentage points, the effect is not obvious, so the filter aid dosing pipeline opening is set at 50% is the most reasonable.

4.3 Personnel skills

The veteran workers, who are skilled in operation, make and explain the daily operation and maintenance courseware of plate and frame filter press, and require the whole field to have regular training and practical practice. The maintenance director classifies and summarises the problems of daily operation of the plate and frame filter press and popularises them, so as to analyse the problems in time and take maintenance measures.

reach a verdict

Optimisation of parameters for pressurised filter work and transformation of the system to optimise the nature of the feed material has increased the hourly capacity of the plate and frame filter press from 20.0t/h to 24.2t/h, and the average moisture of the product has been reduced from 33.78% to 30.46%, which has reached the expected goal of the project. After the transformation and optimisation, the cation usage of Ohtai Coal Processing Plant was reduced by 2% and anion usage was reduced by 3%, which is expected to save about 60,000 yuan of pharmaceutical cost per year. The medium consumption has been reduced from 0.73kg/t to 0.69kg/t, with an average balance of 0.04kg per tonne of raw coal, saving 240,000 RMB in medium cost per year. Plate and frame filter press cake average moisture can be reduced by 3.32%, the annual output of fine coal slurry 145t/h, through the weighted average calculation can be deduced, the average calorific value of blended coal can be improved 75.36kJ/kg, it is expected that the annual income of 2 million yuan.

Welcome to call us for consultation, technical exchange, and material experiment.

Enquiry: 188517-18517

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses