As an efficient and reliable solid-liquid separation equipment, screw filter press is widely used in industrial production. It uses the rotation of the screw to generate pressure, so that the material forms a cake on the filter cloth, thus achieving solid-liquid separation. How much does a screw filter press cost? This article will discuss it.

I. Types and specifications of screw-type filter presses

Screw filter press can be divided into horizontal and vertical according to the structure form, and can be divided into motor drive and hydraulic drive according to the driving method. The price of different types and specifications of screw filter presses will be different. Common specifications are 250, 450, 630, 800, 1000, etc. Each specification has corresponding filtering area and pressure parameters.

Second, the factors affecting the price of screw-type filter presses

1. Equipment material: the quality and thickness of the material of the screw filter press directly affect its price. High-quality materials can ensure the stability and life of the equipment, but the price is also relatively high.

2. Manufacturing process: the manufacturing process of the equipment also affects its price. Fine manufacturing process can improve the performance and service life of the equipment, but the price will also increase accordingly.

3. Degree of automation: the higher the degree of automation, the higher the price of the screw-type filter press. Automatic filter press can reduce manual operation and improve production efficiency, but the price is also relatively high.

4. Manufacturer's brand: The price of screw filter presses may also vary among different manufacturers and brands. Well-known brands usually have higher quality assurance and after-sales service, so the price is relatively higher. However, choosing a well-known brand can also reduce long-term operation and maintenance costs.

5. Filtering area and specifications: The larger the filtering area and specifications, the higher the price of the screw-type filter press. Large filtering area can increase productivity, but the price also increases accordingly.

6. Additional functions: In addition to the basic filtration function, some screw filter presses are equipped with other additional functions, such as heating, cooling, stirring and so on. The more additional functions, the higher the price.

7. Market demand: the market demand for screw-type filter presses will also affect their prices. If the market demand is large, the price may rise accordingly; on the contrary, if the market demand is small, the price may fall accordingly.

III. Price range of screw-type filter presses

According to market conditions and survey data, the price of screw filter presses is generally between tens of thousands of yuan and hundreds of thousands of yuan. The specific price also needs to be determined according to the actual demand and configuration requirements. The following are some common examples of screw filter press prices:

1. Small manual screw-type filter press: the price is around tens of thousands of yuan, suitable for small-scale solid-liquid separation needs.

2. Medium-sized automatic screw-type filter presses: priced between tens and hundreds of thousands of dollars, suitable for medium-sized solid-liquid separation needs.

3. Large-scale automatic screw-type filter press: the price is between 100,000 yuan and hundreds of thousands of yuan, suitable for large-scale solid-liquid separation needs.

It should be noted that the above price is only a reference range, the actual purchase also needs to be based on the specific configuration, manufacturer brand, after-sales service and other factors for comprehensive consideration. It is recommended to choose regular channels to buy, to avoid the safety hazards and risks associated with the use of low-priced low-quality products.

Fourth, how to buy the right screw filter presses

When buying a screw filter press, you need to pay attention to the following points:

1. Clearly demanded: according to the actual production needs, to determine the required equipment models, specifications, performance parameters and use of the occasion. At the same time need to consider the processing capacity of the equipment, efficiency, stability and other requirements.

2. Understanding the market situation: Understand the market situation of the screw filter press market and the product characteristics of different manufacturers in order to compare and choose. Relevant information can be obtained through market research, Internet search and other ways.

3. Choose regular manufacturers: Choose qualified and experienced regular manufacturers to ensure the quality of equipment and service reliability. You can check the manufacturer's relevant certificates, quality management system certification status and so on.

4. Consideration of cost-effective: in the purchase of equipment needs to be considered comprehensively when the performance, price and long-term operating costs and other factors, choose the best cost-effective products. Do not blindly pursue low prices and ignore the quality and service life of the equipment.

5. Understanding maintenance costs: Understanding the maintenance costs of equipment and the supply of spare parts, so as to carry out effective cost control in long-term operation. You can ask the manufacturer for relevant maintenance programmes and service support, etc.

6. Reference to user reviews: You can view the reviews and feedback of other users on different manufacturers through channels such as the Internet or social media in order to better understand the reputation of the manufacturers and the quality of their services.

7. After-sales service: Choose manufacturers with perfect after-sales service to ensure that equipment problems can be solved and repaired in a timely manner. The service capability of the manufacturer is one of the important factors in measuring its quality.

8. Technical support: When buying and selling, you need to consider the technical support and services provided by the manufacturer in order to get professional guidance and help in the process of use. Technical support can solve the problems encountered in the operation of the equipment and provide solutions to ensure the normal operation and service life of the equipment.

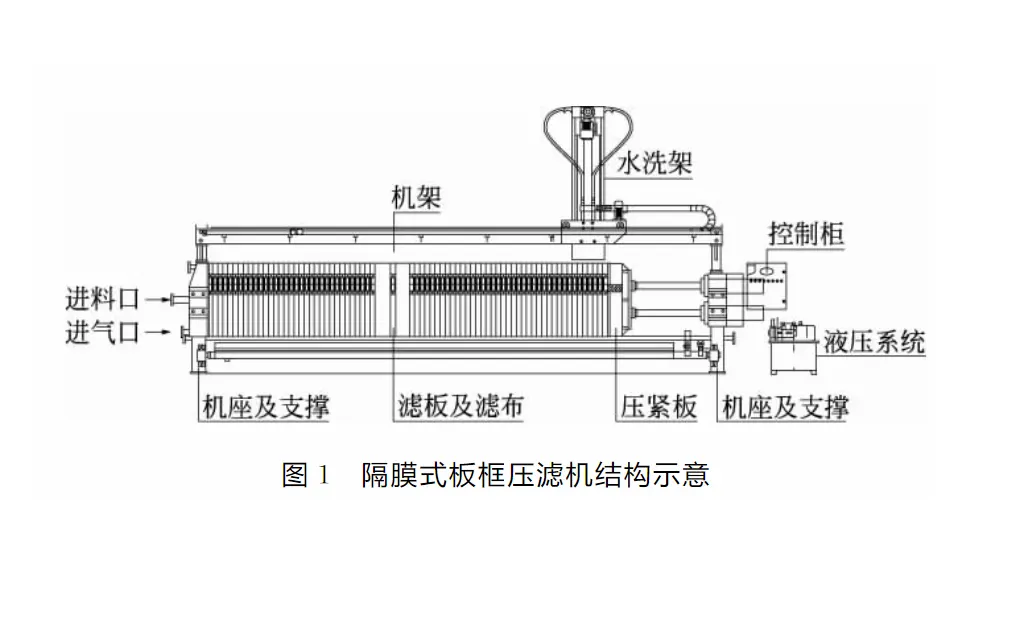

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses