0 Introduction

With the rapid development of social economy, China's consumption of copper metal demand is growing, copper smelters are also increasing, and the construction scale is increasing. Copper slag as a solid waste produced in the process of copper smelting, each year China's smelting enterprises new copper slag amounted to about 10 million tonnes, and showed a year-on-year increasing trend. The simple storage of copper slag occupies land and pollutes the surrounding environment. Because the copper slag still contains a certain amount of copper metal, but also cause a waste of resources. China belongs to the copper ore shortage countries, for the comprehensive recovery of valuable metals in copper slag, has an important significance. At present, domestic and foreign copper smelting enterprises have corresponding slag comprehensive recovery system, used to recover copper, iron and other valuable metals in the copper slag, while the final tailings can be used as building materials sold to cement plants and other enterprises. For the copper concentrate recovered by the copper slag sorting system, it needs to be mixed with the copper concentrate powder purchased from the smelter and then returned to the smelting system, so there is a certain requirement for the moisture in the copper concentrate. This requires the use of a suitable dewatering process to ensure that the moisture in the copper concentrate can meet the smelting requirements. Due to the relatively fine particle size of copper concentrate from slag sorting, filtering and dewatering is difficult. In the past, most of them used ceramic filters, and the water content of the filter cake is generally between 12% and 18%, with high water content. A copper smelter in Guangxi copper concentrate dewatering process using plate and frame typefilter pressThe moisture is controlled at around 10 per cent, which meets the requirements of the downstream smelting process.

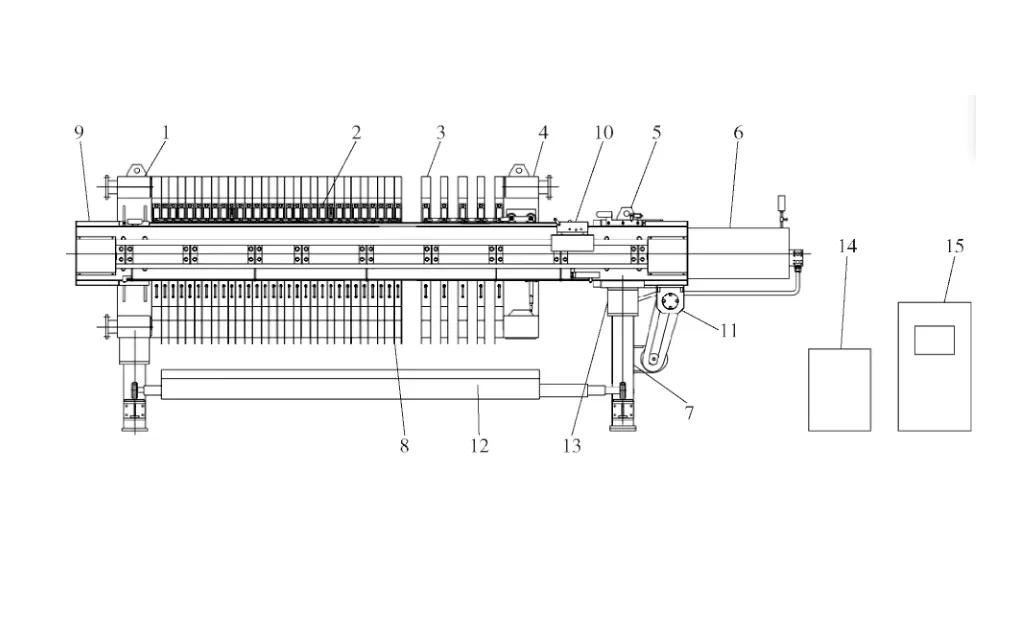

1Plate and frame filter pressesThe working principle of plate and frame filter press is a kind of intermittent solid-liquid separation equipment, which is composed of filter plates and frames arranged to form filter chambers, and under the pressure of feed pump, the slurry will be sent into each filter chamber, and the solids and liquids will be separated through filter media, which is characterised by simple structure, high pressure, and low water content of filter cake. The mechanism of plate and frame filter press is shown in Figure 1.

1. fixed platen assembly 2. filter plate handle 3. filter plate 4. movable platen assembly 5. beam assembly 6. hydraulic cylinder 7. base 8. filter cloth 9. main beam assembly 10. pulling plate drive mechanism 11. pulling plate deceleration mechanism 12. flap mechanism 13. weighing system 14. hydraulic station 15. electronic control cabinet

Plate and frame filter press realises the filtration and dewatering of slurry through the processes of filter plate pressing, slurry pump feeding, pressing and dewatering, blowing and dewatering, pulling off the filter plate and discharging. Its main working principle is as follows:

(1) Before feeding, the hydraulic station is started, and the hydraulic cylinder tightens the filter plate of the filter press, so that the filter plates are stacked on top of each other to form a closed filtering studio; the slurry pump transports the slurry to each filtering studio (the feeding pressure is about 0.8MPa), and the pressure of the slurry pump causes the filtrate to be discharged through the filtering cloth; the solid particles are retained by the filtering cloth to form the filter cake. When the filter cake reaches the appropriate thickness, stop feeding.

(2) Open the compressed air valve, the compressed air into the filter studio, high-pressure gas uniformly squeeze saturated filter cake, particle gap gradually reduced, the excess filtrate within the cake through the filter cloth outside.

(3) After pressing and dewatering, continue to introduce compressed air into each filtering studio (0.6~0.8MPa), the high pressure strong wind through the filter cake and filter cloth will bring out the residual water in the filter cake and blow dry the filter cake.

(4) After the dewatering process is completed, the automatic plate pulling device will pull open each filter plate in turn, and the filter cake between the plates will be discharged by its own weight, completing a filtration cycle.

2 Performance characteristics of plate and frame filter press Plate and frame filter press has the following characteristics compared with ceramic filter and vertical filter press:

(1) Compared with ceramic filter, the moisture content of filter cake is low. Plate and frame filter press through the feed squeeze, press and blow-dry three-stage filtration process, can significantly reduce the water content of the cake, especially for the specific gravity of the larger, finer particle size of the slag separation of copper concentrates, the filtered moisture can basically be controlled at about 10%, the filtration effect is significantly better than the ceramic filter.

(2) Although the water content of the cake of the plate and frame filter press and vertical filter press are both about 10%, the plate and frame filter press has the following advantages compared with the vertical filter press: fewer auxiliary equipments are required; the filter plate is placed vertically, and the replacement of the filter cloth is convenient and quick; the equipment has a low failure rate, and it is easy to operate.

(3) Filter press plate pressing, slurry pump feeding, pressing dewatering, blowing dewatering, pulling off the filter plate discharge and other processes are centrally controlled by PLC operating system, with a high degree of automation, which can achieve automatic operation without manual intervention and reduce the labour intensity of workers.

3 Problems that should be paid attention to in the production process Because the plate and frame filter press is intermittent operation equipment, the daily operation and maintenance is especially critical, in the use of equipment, improper use will not only affect the long-term stable operation of the equipment, but also affect the water content of the filter cake. In the production process, the following issues should be noted:

(1) slurry through the slurry pump feed to the filter press before, it is best to set a layer of grille screen, to prevent large particles or debris into the filter press, so as to avoid the feed channel blockage caused by the uneven force of the filter plate cavity stagnant bias broken plate, filter cloth by the sharp particles caused by the scouring of the breakage of the situation;

(2) The front end of the feed should be equipped with a certain volume of stirring tank, through continuous stirring to ensure that the concentration difference between the upper and lower layers of the slurry is less than 5%, and the stable feeding can ensure the formation of coarse and fine filter cake inside the filter chamber, which is convenient for the unloading of the filter cake and does not stick to the filter cloth;

(3) During the production process, regularly clean up the accumulation of material on the sealing surface under the filter plate to avoid slurry spraying and air leakage caused by the poor sealing of the filter plate due to the clamping of material on the sealing surface.

4 Summary in the smelter of copper slag sorting system construction of the early stage, generally the second stage of copper concentrate dewatering using ceramic filter, but the filtered copper concentrate moisture are higher, can not smelting process requirements, while the transport is also a certain degree of difficulty. With the emergence of vertical filter press, ceramic filter is gradually eliminated. Vertical filter press filtration effect is good, low water content of the cake, can meet the requirements of the smelting process, but this filter press due to more supporting equipment, so the failure rate is higher, operation, maintenance are relatively large workload. In the slag sorting system of a smelter in Guangxi, the plate and frame filter press was first used for two-stage dewatering, achieving a cake water content of about 10%, which not only meets the requirements of the smelting process and transportation, but also reduces the downtime of the equipment, reduces the labour intensity of workers, and opens up a new path for the future slag sorting system for the dewatering process of copper concentrates.

Disclaimer: The copyright of this article belongs to the original author and the original source.

Welcome to call us for consultation, technical exchange, and material experiment.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses