outlined

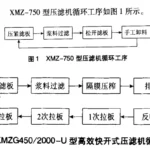

Rapid and efficient diaphragm filter press adopts multi-port feeding, multi-cylinder pressing, rapid sub-group sub-pulling, automatic unloading, diaphragm pressing, automatic control, featuring large processing capacity, fast working cycle and high degree of automation, and it is a kind of fast, efficient and economical box-type solid-liquid separation equipment.

2.0快速型压滤机结构型快速高效隔膜压滤机由主机、液压系统、电控系统、卸料机构等组成。主机由机架部分、滤板组件、滤板拉开合拢机构、滤板压紧机构组成。

2.1机架机架是机体的主体结构部分,两平行的主梁分别与固定压板组件和后支架相连构成矩形框架,主梁用以装配滤板拉开合拢机构并支撑滤板组件、压紧机构、自动卸料机构等零部件。

2.2滤板组件压榨滤板组件和过滤板组件交替排列在主梁上,在滤板过滤面覆盖一层滤布,形成一个个过滤腔室,压榨滤板组件中,滤板和滤布之间覆盖有隔膜。过滤时,料浆在料泵压力作用下,经固定压板、进料滤板、活动压板上的进料口进入各个过滤腔室,料浆中的液体借助入料压力作用,透过过滤介质汇集到排液孔,经明流孔和暗流孔同时排出。料浆中的固体颗粒则被过滤介质截留在过滤腔室内形成滤饼。当物料充满过滤腔室时,过滤阶段结束,压缩空气进入隔膜与滤板之间,使得隔膜产生弹性变形挤压滤饼,进行二次压榨脱水。

2.3滤板压紧机构活动压板带动活动油缸座及滤板初步合拢后,活动油缸座上个锁紧油缸带动滑块组件伸出,限制活动油缸座后移。主油缸活塞杆伸出,压紧滤板。电控系统自动控制液压系统使主油缸、副油缸同时进入保压状态。当滤饼形成并压榨脱水后,主油缸带动副油缸、活动压板松开退回,锁紧油缸带动滑块组件缩回复位,滤板拉开合拢机构开始工作。

2.4卸料机构卸料油缸的伸出与缩回实现卸料大梁的上下运动。摆动杆上的滤布随之上下移动,使滤饼脱落。

2.5液压系统它是压滤机的动力装置,由油泵、液压控制元件、液压执行元件、高位油箱、液压管路等组成。各执行油路均设有减压阀,主油路设置系统溢流阀。2.6控制系统由控制部分、信号部分、执行部分组成,具备手动、自动化操作功能。

(1) The control part consists of programmable controller, programmable text display terminal and control panel, buttons, switching power supply, AC contactor and so on. It takes the programmable controller and programmable text display terminal as the core, and sends out action instructions to the mechanism according to the input procedure and the feedback information of the signalling system.

(2) Signal system main cylinder expansion and contraction limit; filter plate pull open and close limit; slider assembly lifting limit; hydraulic system oil pressure measurement and other sensors will be institutional action information and hydraulic system parameters feedback to the control part.

(3) the implementation of the part of the hydraulic station oil pump motor, electromagnetic reversing valve, pipeline system electronic control valves, etc., according to the instructions issued by the control part, to complete the action requirements of each step.

(4) Automatic operation During automatic operation, the control system starts the motor oil pump, and the motor runs without load. The control system issues a command, electro-hydraulic directional valve action, the main cylinder rodless chamber rapid action, vice cylinder from the high level tank oil replenishment with the action. The pressure of the hydraulic system rises after the filter plate is pressed, the system sequence valve opens, and the pressure of the main and sub-cylinder rises at the same time. When the pressure reaches the set upper limit value, the pressure sensor feeds back the signal to the control system, the control system sends out the motor oil pump stopping instruction, and the main cylinder is in the process of keeping pressure. When the pressure drops to the set lower limit value, the control system starts the motor oil pump again according to the feedback signal, until the pressure rises to the set upper limit value again. The feed pump presses the slurry into each filter chamber for filtration, and after the cake fills the filter chamber, the compressed air enters between the diaphragm and the filter plate for the second pressing and dewatering. At the end of pressing, the motor oil pump starts again, the electro-hydraulic reversing valve moves, the main cylinder rod chamber feeds oil, and the vice cylinder follows. Filter plate loosening, control locking cylinder electromagnetic reversing valve action, locking cylinder drive slider assembly reset, control a pull-open hydraulic motor electromagnetic reversing valve action, the motor through the drive chain drive movable pressure plate, movable cylinder seat moving pull-open filter plate unloading. Once pulled open in place, the control system to start the second pull-open hydraulic motor for the second unloading, the second in place, through the electromagnetic reversing valve reversing action, making the second pull-open motor reversal, feed filter plate drive filter plate three times pulled open unloading. After the end of unloading, start a pull-open motor reversal, drive the activity of the pressure plate, the activity of the cylinder seat and the filter plate together in place, the locking cylinder drives the slider assembly will be the cylinder seat locking, to complete a cycle of work, the motor oil pump stops working.

(5) Manual operation manual operation, through the control cabinet panel buttons step by step to complete the closure and compression, into the material filtration, pressing dehydration, grouped unloading unloading a complete stage of operation.

2.7快速压滤机自控系统

(1) System configuration for the completion of intelligent control, the selection of programmable controllers. It is a module for road switching input and road switching output. Block for the road switching input, road switching output expansion module. Input signals are buttons, oil pumps and material pumps, conveyor operation feedback signals, valve feedback signals. Output signals are: indicator, alarm, intermediate relay for control (oil pump, material pump, conveyor, valve, etc.). It is a miniature programmable terminal of programmable controller, which is used for on-site monitoring in the control system of rapid filter press, real-time display of the working status of each process of the system, precise positioning of process alarms and faults, and setting of process parameters during automatic operation, etc. It also collects the external switching signals, which can be used for the control of filter press. It collects the external switching signals and controls the output signals, indicator lights, alarms or intermediate relays by running the control programme stored in it, so as to achieve the control of the field equipment and complete the control functions required by the process.

(2)软件编制采用梯形图编程语言,根据工艺要求首先在计算机上应用编程软件编制应用程序,然后通过编程电缆与通信进行在线调试,调试成功后即可将程序下传至。程序流程:初始化阀门!参数设定!手自动检测!临时停车检测!故障检测!油泵启动!压紧!保压!补压!入料!压榨!反吹!卸料!复位。经过近运行,效果良好。

Welcome to call us for consultation, technical exchange, and material experiment.

Enquiry: 188517-18517

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses