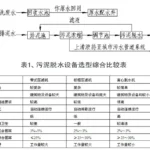

introductory

Shanxi Kai Luan Lujiatuo Coal Preparation Plant was designed and built by Polish Coal Preparation Design Institute in 1968. At the early stage of construction, the capacity of the plant was 2.4 million tonnes/year. Since 2000, Lvmin Coal Processing Plant has carried out the technological transformation of various processes successively, and now it is 80 ~ 13mm class lump coal vertical wheel heavy media system, 13 ~ 0.5mm class final coal three products cyclone system, <0.5mm class flotation system; the raw coal washing capacity has also been increased from 2.4 million tonnes/year to 3 million tonnes/year by the original design, and the grades of the raw coal being washed are fertiliser and coking coal, and several products such as coal concentrate, lump coal, final coal, slurry, etc. have been developed. The products are fine coal, lump medium coal, final medium coal, slurry and so on.

Although the coal processing plant has been renovated for many times, the flotation tail coal is still recovered by slurry sedimentation tank, and it is difficult to achieve closed-circuit recycling of washing water, which is not in line with the requirements of environmental protection. Therefore, Lv Mine Coal Wash Plant has modified the flotation tailing recycling system, and put into use for the first time the fast diaphragm filter press to recycle the flotation tailing, and realised the closed-circuit recycling of the washing water.

Rapid Diaphragm Filter Press Working Principle and Structure

- Working Principle

(coll.) fail (a student)filter pressWhen working, the filter plate will be closed together by the driving mechanism and chain wheel drive, and all the filter plates will be pressed between the movable head plate and fixed tail plate, so that the filter chamber will be formed between the neighbouring filter plates. Under the action of the pump, the filter slurry enters the chamber through the feeding pipeline from the middle end of the fixed pressure plate, the feeding filter plate and the feeding hole at the upper end of the movable pressure plate respectively, and the liquid is discharged under the action of the pressure, while the solid particles are retained in the chamber by the filter cloth. When the filter cake is formed, 0.6 ~ 0.7MPa compressed air is passed between the press plate and the diaphragm, so that the diaphragm produces the elastic deformation of squeezing in the direction of the filter cake to carry out the dewatering for the second time. In order to prevent the unfiltered slurry in the inlet pipe from entering the conveying system with the filter cake, the compressed air of 0.6~0.8MPa is conveyed through the fixed platen, the filter plate assembly, the driven filter plate assembly and the movable platen, and the unfiltered slurry in the pipe is blown into the slurry settling tank, so as to ensure the moisture content of the filter cake after the dewatering of the press. After the cake dewatering is completed, the piston rod of the press cylinder is retracted, and the hydraulic motor in the pull-open mechanism drives the sprocket and chain bar to move, so that all the filter plates can be pulled open and discharged continuously in several groups.

- fabric

Fast and efficient diaphragm filter pressesIt mainly consists of frame, filtering element, driving system, pressing system, hydraulic system, electric control system, etc. The frame mainly consists of main beam, fixed press plate, rear support and auxiliary support parts. The frame mainly consists of main beam, fixed pressure plate, rear support and auxiliary support parts; the filtering part consists of pressing filter plate components and filtering filter plate components arranged alternately on the main beam, with a layer of filter cloth covering both sides of two kinds of filter plates to form a filter chamber. The filter plate is connected to the filter plate, the filter plate to the movable press plate and the filter plate to the drive unit by means of high-strength circular chains; the movable press plate is connected to the cylinder on the movable cylinder block. The pressing part is composed of movable cylinder seat and slider assembly; the hydraulic system includes oil pump, hydraulic control components, hydraulic actuating components, high level oil tank, etc.; the electric control system is composed of electric control cabinet, mechanical action travel switch of filter press, oil pump motor and solenoid valve of hydraulic station, and electric control valve of slurry and compressed air pipeline, etc., which completes the manual or automatic operation of the cyclic working process of the filter press.

3.Rapid diaphragm filter press common troubleshooting:

| place | failure performance | Reason for failure | Treatment |

| pressure system | No or insufficient pressure | 1. Oil system failure | Service or replace the oil pump |

| 2、Oil case steering is not right | Correcting the steering | ||

| 3、Excessive wear and tear of oil spring parts | Repair or exchange parts | ||

| 4、Relief valve failure | Adjustment of colour check and cleaning of relief valves | ||

| 5、Bad cylinder oil seal | Replacement of oil seals | ||

| 6, electromagnetic reversing valve is not in place | Clean or replace the solenoid reversing valve | ||

| 7、The oil level is too low | Replenishment of fluids | ||

| 8、Hydraulic pressure gauge failure or damage | Repair or replacement | ||

| lack of traffic | 1、Hydraulic pump barren serious | Inspection or replacement of oilseed rape | |

| 2、Insufficient oil | Replenishment of fluids | ||

| 3、Oil filter port clogging | Clean oil filters | ||

| Vibration and noise | 1、Insufficient oil | Replenishment of fluids | |

| 2、Suction pipe leakage | lit. examine and deny the secrets of the Book of Songs (idiom); to search for and retrieve information | ||

| 3、Oil filter clogging | Clean oil filters | ||

| 4、Cylinder seals are too tight | Adjust or replace seals | ||

| filter plate | Filter plate slurry | 1、Compression plane has impurities | Remove impurities. Clean sealing surfaces |

| 2、Breakage of press diaphragm | Replacement or repair | ||

| 3、Filter cloth folding | Lapin Filter Cloth | ||

| 4、The feed pressure is too high | Reduced feed pressure | ||

| 5、Insufficient compression pressure | Adjusting hydraulic system pressure | ||

| The filtrate is turbid | 1、Damaged filter cloth | Mend or replace | |

| 2. Filter cloth density thin | Use of filter cloths of suitable density | ||

| (lit.) won't work as a cake | 1, into the material strength is too small filtration performance is poor | Increased feed pressure | |

| 2, such as material concentration is low | Increase the concentration of the material | ||

| Low filtrate volume | 1. Into the LI blockage | Built-in feeder | |

| 2. Low filtering or pressure stopping pressure | Increase in repulsive force | ||

| Poor movement of the filter plate | Unsynchronised movement of filter plates | Adjust the chain length. Align left and right | |

| Filter plate does not move | Check oil pump, motor and chain. | Identify problems and deal with them in a timely manner | |

| cylinder | Compression without backing up, backing up without compression | 1, electromagnetic directional valve coil burnt | Replace the directional valve coil |

| 2、Directional valve spool long dead | Flush or replace spool | ||

| pneumatic pump | Bad oil absorption | Poor or loose suction hose seal resulting in no air intake | Remove the oil suction pipe, re-glue and tighten it, and fill the cylinder with oil. |

| No oil suction at idle | |||

| oil filter | the oil does not pass slowly | Too much dirt. | Remove for cleaning |

| compress

cylinder |

No backing up, no oil leaks | Deterioration of oil seals | Replacement of oil seals |

| Liquid-filled valve questions | Inlet and outlet oil check valves are entangled or blocked by dirt, so that the ball can not be reset or the spring base is loose, should be removed and cleaned and adjusted |

4. Transformation effect

Improved wash water quality and circulating water concentration after the rapid diaphragm filter press was put into operation.

From 60g/litre before renovation to less than 0.4g/litre, the content of fine particles is reduced to less than 20%, the water quality is clearer, and clear water coal washing is realised.

5. Transformation benefits

Before the transformation of coal washing every day with about 4,000 tonnes of water, after the transformation down to 1,000 tonnes, according to the sale price of 2 yuan per tonne of water, then the annual savings of water costs: 2x (4,000 - 1,000) x 330 = 1,980,000 yuan

According to the calculation of 3 million tonnes of raw coal being washed in Lujiatuo annually, 600,000 tonnes of raw coal is fed into the flotation each year (20% of the total amount of raw coal is fed into the flotation). Since Lujiatuo coal is more difficult to be selected, the flotation tailings production rate is calculated based on 50% of flotation feed, and the annual production of coal sludge (filter cake) is 300,000 tonnes. The price of each tonne of coal slurry in Lujiatuo mine is RMB 210 (including tax), and the price of each tonne of filter cake is RMB 265 (including tax), so the annual increase in economic benefits is: (265-210) x 30 = 16.5 million yuan.

Annual efficiency = water saving benefit + benefit of increased revenue from coal slurry sales: 198 + 16.5 = 18.48 million yuan.

concluding remarks

Rapid diaphragm filter press is the key to realise the closed-circuit recycling of coal slurry water with fast filtration, large processing capacity and good filtration effect. After the filter press is put into use in the coal slurry water system of Lujiatuo Coal Wash Plant, it ensures the quality of washing water, reduces the influence of deterioration of washing water on the flotation system, and achieves good economic effect and environmental benefit.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses