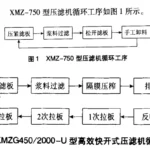

Ultra-high pressure diaphragm filter press:

Ultra High Pressure Diaphragm Pressfilter press(XAMYZGFS-800-2000 type) is our company adopts the latest technology, information technology, intelligent technology and the company's patented technology, multi-cylinder hydraulic compression, multi-head feeding, grouping fast pulling the plate way, so as to achieve fast feeding, fast diversion filtration, fast pulling the plate unloading, shorten the filtration cycle, and improve the separation and filtration of the filtering by the arrangement of the diaphragm and the compartment filter plate to form the filter chamber, under the pressure of the feeding pump, the slurry will be fed into the filter chamber. The slurry is fed into the filter chamber under pressure, and the solids and liquid in the slurry are separated through the filter medium (filter cloth). When the solids in the slurry form a cake, air is passed to the diaphragm to press the solids in the filter chamber sufficiently and reduce the water content. For the filtration of viscous materials and users with higher requirements for water content, the machine has more unique characteristics. The contact surfaces with materials, such as the fixed pressure plate, movable pressure plate, inlet and outlet pipes or flanges, etc., are made of stainless steel 304/316L or PP to prevent corrosion according to the actual needs of customers.

Advantages of Ultra High Pressure Diaphragm Filter Press:

The filter plate of ultra-high pressure diaphragm filter press is made of reinforced polypropylene moulding, the diaphragm and polypropylene plate are inlaid together, which is strong and reliable, not easy to fall off, and has a long service life. The oil tank is made of high-quality steel plate welding (stainless steel can be used according to the needs of customers), and effective surface anti-corrosion treatment is adopted. The oil pump and hydraulic components used in the hydraulic system are all famous brands at home and abroad (Shanghai Shenfu, Huadao, Beijing Huade, Germany Rexroth, etc.) When the whole machine is working, the oil pump and hydraulic components are all famous brands at home and abroad.filter pressHydraulic system is stable, safe and reliable, no oil leakage phenomenon, trouble-free operation for more than 5 years.

Ultra high pressure diaphragm filter press performance:

The advantages and working principle of ultra-high pressure diaphragm high-efficiency energy-saving filter press solid-liquid separation equipment are mainly different from the current ordinary solid-liquid separation equipment is that a layer of elastic membrane is added between the filter plate and the filter cloth. In the operation process, when the end of the feeding material, you can inject high-pressure fluid medium between the filter plate and the diaphragm, at which time the whole diaphragm will bulge and press the filter cake, to achieve further dewatering of the cake, that is, press filtration. The diaphragm combination plate consists of a centre plate with double-sided dovetail grooves and the diaphragm on both sides, which is closely inlaid, thus forming two sealed air pockets. The dovetail groove is processed by large-scale gantry CNC milling machine, with high precision and no air leakage. When compressed air is fed into the airbag, the airbag expands to squeeze the filter cake inside the filter chamber with high pressure, thus the solid content can be greatly increased in a very short period of time.

Compared with ordinary press filtration the solid content can be increased by 10%-30%.Normally, if the water content of the filter cake is reduced by 7%, the energy consumption for drying is reduced by half. After filtering to a certain degree, close the feed valve, the hydraulic drive generated by the slurry with very low solid content is changed to press pressure, so that the liquid remaining in the filter cake is squeezed out. In this way, the solid content of the cake is rapidly increased in a very short period of time, because the cycle of the whole filtration process is shortened, so that the production capacity of the solid-liquid separation equipment is greatly increased, and the handling capacity is significantly increased.

Scope of application of ultra high pressure diaphragm filter press:

wagondiaphragm filter pressIt is the ideal equipment for solid-liquid separation of various suspended materials to improve the separation efficiency and reduce the water content of filter cake. Widely used in petroleum, chemical, printing and dyeing, metallurgy, medicine, food, textile, electroplating, papermaking and urban sewage treatment and other industries in the field of solid-liquid separation.

Contact Us

Selection:188-517-18-517

Mailbox:suton@su-ton.com

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses