Guanglian Expressway Project is the largest single investment project of CCCC Group, with a total length of 231.7 kilometres, passing through Guangzhou, Qingyuan and other places, spanning across the Jiejiang River, Beijiang River, Lianjiang River and Qinglian River, and threading along the green mountains and beautiful water. Among them, the second standard of Division I constructed by the Four Navigation Bureau is 9.88 kilometres long, located in Aotou Town, Conghua District, Guangzhou City. As one of the five demonstration towns in Guangzhou City for high grain yield, the local environment and water conservation requirements are extremely high, "so that every grain of rice can drink clean water" is not only the goal of the project, but also the bottom line. How to answer the question of ecological and environmental protection in the construction of the project, CCCC builders delivered an excellent answer sheet.

In September, the project entered the bridge pile foundation construction stage, which generated a large amount of slurry during pile filling. At the beginning of the construction, the project adopted the conventional method to deal with the mud generated during pile filling, i.e., through the grouting pool sedimentation, filtration and then continue to be recycled to maintain the stability of the drilling wall. However, with the accelerated progress of the project, more and more mud was generated. Recycling alone is far from being able to consume the mud stock, and if it is not handled in a timely and effective manner, the overflowing mud will pollute the environment of the neighbouring surface water bodies, and the salts, alkalis and rock salts contained therein will also lead to soil crusting in the vicinity of the water bodies.

Never let a drop of mud flow into nearby farmland.

"Tang Shaohua made up his mind. Initially, the project decided to commission a professional organisation toSludge Filter PressDisposal is carried out. After market research, the project estimated that the cost of transporting and treating each cubic metre of mud was as high as 100 yuan. Looking at a pool of mud, Tang Shaohua was worried, "The cost is too high, the distance is also a bit far, a back and forth progress is delayed." At the time of a stalemate, the mechanical department of the new staff Fu Baiwei boldly proposed: "sewage and mud treatment mechanism is through the extrusion filter to achieve solid-liquid separation, why don't we transform the sewage treatment machine upgrades it?" After a joint discussion, the programme of upgrading the sewage treatment machine was unanimously adopted.

Filter presses turn waste into conservation

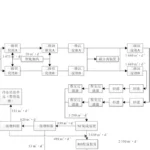

Said to do, Tang Shaohua led the project technical backbone will be moved to the office to the mixing station, an idle sewage treatment machine dismantled in pieces, additional control valves in the hydraulic machine to regulate the direction of the liquid flow in the hydraulic system, pressure and flow, the success of the pressure value of the pressurised filter plate from 5.2 MPa to 6.5 MPa, to meet the requirements of the mud filtering requirements. "filter plateSuccess 'out of the cake'!" The busy one week "test room" finally opened. Not yet from the success of the excitement back, the project team and tripped over the feet, after many test machine, slurry pump suction pipe and bottom valve is blocked frequently. Through the waste slurry sampling and testing, Tang Shaohua found that the waste slurry density, containing drilling slag, sand and soil. He first used cyclone desander to deslag waste slurry, while increasing the calibre of slurry pump suction pipe, a perfect solution to the problem of silt blockage. So far, the sewage treatment machine has changed, successfully "transformed" for theSediment filter pressAfter the slurry is pressed, the solid-liquid separated "clear water" flows from the nozzle on the side of the filter plate to the set tank. After the slurry is pressed, the solid-liquid separated "clean water" flows from the side nozzles of the filter plate to the well-set sink, and is discharged to the clean water tank, and then appropriate pharmaceuticals are added to ensure that the water treatment is stable and meets the standards. According to statistics, the new sediment filter press will shorten more than 2,000 man-hours and save more than 2 million yuan for the project.

Vowing to go green to the end

The project will be environmentally friendly throughout all aspects of construction and production, the use of solar energy and other clean power to reduce generator fuel consumption, in the gravel yard, the bridge and other construction areas of the construction of enclosed construction and with high-pressure fogging dust precipitator and other purification of the surrounding environment. At this time, the distant fields, the seedlings gently shake, Tang Shaohua eyes firmly looking at the green rice paddies, looking forward to the day of full of gold.

Reprinted: Traffic Construction Newspaper Four Navigation Bureau

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses