In order to guide localities to carry out the construction and operation management of urban sewage treatment plant sludge treatment and disposal project, comprehensively promote the sludge treatment and disposal of urban sewage treatment plant in our province, and promote the resourceful utilisation of sludge, our department has formulated the "Technical Guidelines for the Treatment and Disposal of Sludge from Urban Sewage Treatment Plants in Sichuan Province (for trial implementation)". It is now issued to you, please refer to the implementation of the actual situation in the region.

Sichuan Provincial Department of Housing and Urban-Rural Development

Date and place of birth: 9 September 2021

Technical Guidelines (Trial)

The sludge of urban domestic wastewater treatment plant (hereinafter referred to as "sludge") referred to in this technical guideline refers to the semi-solid or solid material produced in the process of urban domestic wastewater treatment, excluding slag, scum and sand.

The sludge-derived products (hereinafter referred to as "sludge products") referred to in this technical guideline refer to the derivatives that can be utilised in a resourceful manner after the sludge of urban domestic wastewater treatment plants has been reduced, stabilised and rendered harmless.

This technical guideline is applicable to the management and technology selection of sludge generation, storage, treatment, transport and final disposal in order to enhance the science of sludge treatment and disposal management decisions.

Sludge treatment and disposal should follow the principles of source reduction and whole-process control, strengthen source control of toxic and hazardous substances, and select appropriate sewage and sludge treatment processes according to the requirements for the final safe disposal of sludge and the characteristics of sludge.

The goal of sludge treatment and disposal is to achieve the reduction, stabilisation and harmlessness of sludge; and to encourage the recovery and utilisation of energy and resources in sludge. It insists on achieving sludge treatment and disposal and comprehensive utilisation on the premise of safety, environmental protection and economy, so as to achieve energy conservation and emission reduction and the development of a circular economy.

Local people's governments are responsible for the planning and construction of sludge treatment and disposal facilities; sludge treatment and disposal facility operators are responsible for the safe treatment and disposal of sludge. Local people's governments should prioritise the procurement of sludge products that meet relevant national standards.

Encourage the full use of social resources to treat and dispose of sludge; encourage technological innovation and scientific and technological progress in sludge treatment and disposal; encourage the research and development of new technologies, processes and equipment for sludge treatment and disposal that are suitable for the actual situation in the province and the characteristics of the region.

Local people's governments shall reasonably determine the scale of sludge treatment and disposal facilities in accordance with the planned sludge generation of urban domestic sewage treatment plants; the scale of recent construction shall be determined moderately ahead of time in accordance with the current volume of sewage and the quality of incoming water, so as to give full play to the investment and operational benefits of the treatment facilities.

When urban domestic sewage treatment plants are newly constructed, reconstructed and expanded, sludge treatment and disposal facilities should be planned, constructed and put into operation at the same time as sewage treatment facilities. Sludge treatment must meet the requirements for sludge disposal, and projects that fail to meet the stipulated requirements shall not pass the acceptance; if the current sludge treatment facilities do not meet the requirements for disposal, rectification should be accelerated to ensure the safe disposal of sludge.

Encourage the use of incineration and drying, thermal hydrolysis, anaerobic digestion and aerobic fermentation for harmless treatment. Encourage the use of sludge and kitchen and food waste co-disposal facilities to enhance the comprehensive disposal of urban organic waste. When carrying out the construction of co-disposal sludge facilities, full consideration should be given to the operation of existing local sludge disposal facilities and the use of processes.

When planning and constructing treatment facilities, in addition to technical and economic analyses, attention should be paid to the evaluation of carbon emissions.

Sludge incineration.Sludge incineration can be divided into separate incineration and co-incineration. Encourage the use of sludge incineration process in areas with the conditions, it is appropriate to use drying and incineration of co-incineration, to improve the efficiency of the use of thermal energy of sludge; encourage sludge incineration plant and rubbish incineration plant co-built, and encourage the sludge as a low-quality fuel in the incinerator of coal-fired power plants, cement kilns or brick kilns mixed incineration; and encourage the slag of the slag that meets the requirements of the comprehensive use of building materials.

(1) When sludge is used for separate incineration, the mud quality shall meet the Mud Quality for Separate Incineration of Urban Sewage Treatment Plant Sludge Disposal (GB/T 24602), the incineration slag must be collected, stored, transported and disposed of separately from the incineration fly ash collected by the dust removal equipment; the incineration slag shall be disposed of according to the general solid wastes, and the incineration fly ash shall be disposed of according to the hazardous wastes. Incineration flue gas emission control requirements should meet the "Comprehensive Emission Standards for Air Pollutants" (GB 16297), of which dioxin control should meet the relevant provisions of the "Pollution Control Standards for Domestic Waste Incineration" (GB 18485).

(2) Sludge can be co-incinerated with domestic rubbish, or used as fuel in industrial incinerators, thermal power plant incinerators, the mass of sludge into the furnace should be less than the amount of rubbish (coal-fired) 20%. incineration flue gas emission control requirements should meet the corresponding national pollution control standards.

Comprehensive utilisation of sludge building materials.Comprehensive utilisation of sludge construction materials refers to the inorganic treatment of sludge, which is used to make cement additives, bricks, lightweight aggregates and road base materials. The comprehensive utilisation of sludge construction materials should be promoted in areas with conditions. The utilisation of sludge construction materials should be in line with relevant national and local standards and norms, and strictly guard against secondary pollution in production and use.

(1) When sludge is used to make cement, the design of cement kiln co-incineration should be in line with the current national standard "Design Code for Cement Kiln Co-disposal of Sludge Project" (GB 50757), and the quality of cement made should be in line with the technical performance requirements in "General Silicate Cement" (GB 175), "Silicate Cement Clinker" (GB/T 21372), and "Technical Specification for the Cooperative Disposal of Solid Wastes in Cement Kilns" (GB 30760). ) in the technical performance requirements. The ratio of sludge to total raw material mass (in terms of dry sludge) should not exceed 10%.

(2) When sludge is used to make bricks, the quality of sludge should be in line with the provisions of "Disposal of Sludge from Urban Sewage Treatment Plants Sludge for Brick Making" (GB/T 25031), and the quality of finished bricks prepared from sludge should meet the relevant provisions in the national standards of "Sintered Ordinary Bricks" (GB 5101), "Sintered Porous Bricks and Porous Blocks" (GB 13544) and "Sintered Hollow Bricks and Hollow Blocks" (GB 13545). ) in the relevant provisions. Sludge with low organic matter content is suitable for brick making. The weight ratio of sludge to total raw materials (in terms of dry sludge) should not exceed 10%, and the mixing ratio can be increased appropriately when industrial conditions permit or the products require it.

(3) Sludge can be used as raw materials for the preparation of lightweight auxiliary materials such as ceramic granules. According to the quality of sludge and other raw materials, the ratio of raw materials is determined through tests, and the quality of ceramic granules prepared should meet the technical requirements of Lightweight Aggregate and Its Test Methods Part 1 Lightweight Aggregate (GB/T 17431.1).

Sludge land use.Land use mainly includes land improvement and landscaping, etc. Sludge products that meet the standards after treatment can be used for land use, and the land use should comply with national and local standards and regulations. Sludge products meeting the standards are encouraged to be included in the government procurement list. Sludge products should not be used for land use in locations with large slopes or high groundwater levels, and the use of sludge products for land use is strictly prohibited in drinking water source protection zones. Restricted agricultural use of sludge products that meet the standards is allowed.

(1) When sludge products are used for landscaping, the sludge must be stabilised and harmlessly treated first, and the quality of the sludge should meet the provisions of "Disposal of Sludge from Urban Sewage Treatment Plants, Sludge for Landscaping" (GB/T 23486) and the requirements of relevant standards. It is appropriate to determine the reasonable application range, application amount, application method and application time according to the soil background characteristics and plant habits of different regions. Relevant indicators of groundwater and soil in the place where sludge is used should meet the Groundwater Quality Standards (GB/T 14848) and Soil Environment Quality Standards (GB 15618).

(2) When sludge products are used for land improvement of saline and alkaline land, sandy land and abandoned mine sites, the quality of sludge shall meet the provisions of "Disposal of Sludge from Urban Sewage Treatment Plants and Land Improvement of Sludge Quality" (GB/T 24600), and environmental impact evaluation shall be carried out in accordance with the actual situation in the locality, and approved by the competent authorities concerned before implementation. The relevant indicators of groundwater and soil in the place where sludge is used should meet the Groundwater Quality Standards (GB/T 14848) and the Soil Environmental Quality Standards (GB 15618).

(3) When sludge products are used for agricultural purposes, the sludge must be stabilised and harmlessly treated, and meet the Control Standards for Pollutants in Sludge for Agricultural Purposes (GB 4284) and other relevant national and local standards and regulations in force for agricultural purposes. The sludge products shall pass the environmental impact assessment of site applicability and environmental risk assessment, and be approved by relevant departments before implementation. When sludge products are used for agricultural purposes, the cumulative annual amount should not exceed 7.5t/hm2 (on a dry basis, i.e., with a water content of 0), and the continuous use should not exceed 5 years.

Sludge landfill.Sludge landfill methods include separate landfill and mixed landfill, and it is preferable to use mixed landfill of sludge and domestic waste. Sludge that does not have the conditions of incineration, land use and comprehensive utilisation of construction materials can be disposed of by sanitary landfill. The sludge before sanitary landfill needs to be reduced and stabilised, and the water content should be less than 60%. sludge without dewatering treatment to meet the standard shall not be landfilled in the landfill. When sludge is used in mixed landfill or as landfill cover soil additive, the quality of sludge should meet the provisions of "Disposal of sludge from urban sewage treatment plants Mixed landfill sludge quality" (GB/T 23485). If co-disposal is used, sanitary landfill can be used as an emergency disposal measure when the co-disposal facility fails or is overhauled.

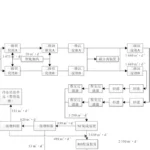

On the basis of conventional treatment processes such as sludge thickening, conditioning and dewatering, suitable sludge treatment technology routes should be selected in accordance with sludge disposal requirements and the corresponding mud quality standards. If the sewage treatment plant does not have the required site conditions, or if the size of the sewage treatment plant is small, the dewatered sludge can be transported centrally to a site with treatment capacity for stabilisation and harmless treatment. After stabilisation and treatment, the sludge shall meet the relevant normative standards. If the treated sludge does not meet the relevant requirements, other measures should be taken for further treatment, and the appropriate disposal route should be taken after the standards are met.

Lime stabilisation.This refers to the process of generating calcium hydroxide and calcium carbonate and releasing heat by adding a certain proportion of quicklime to the dewatered sludge and mixing it evenly. Sludge stabilised with lime can be disinfected and stabilised, and the solids content of the sludge can be increased.

(1) Lime-stabilised sludge is mainly used as an amendment for acidic soils, as a base material for roadbeds, and as a cover soil for landfills. When the subsequent cement kiln injection method is used to produce cement, it can be used to replace the raw material for cement firing in appropriate quantities.

(2) The use of lime stabilisation techniques should take into account the stability of local lime sources, economy and reliability of quality.

(3) Lime stabilisation facilities must be equipped with waste gas treatment equipment, and it is appropriate to use wet dust removal equipment for treatment.

Thermal drying of sludge.Thermal drying of sludge is a process that removes water from sludge by heat transfer between the sludge and a heat medium. To meet the requirements for subsequent disposal of sludge, sludge thermal drying can be used to further reduce the water content of conventionally mechanically dewatered sludge.

(1) When sludge is disposed of by means of comprehensive utilisation of building materials, sludge can be treated by thermal drying. When there is no way of utilising building materials, the sludge can be sanitary landfilled or incinerated after aerobic composting to meet the standard.

(2) The use of sludge thermal drying process should be combined with the use of waste heat, and it is not appropriate to use high-quality primary energy as the main drying heat source or to set up a separate thermal drying process. Encourage the use of biogas heat generated in the process of anaerobic digestion of sludge, waste heat from rubbish and sludge incineration, waste heat from power plants or other waste heat as the heat source of sludge drying treatment.

(3) Indirect heating is preferred for sludge drying equipment.

(4) The thermal drying system must be equipped with flue gas purification and treatment facilities and meet the emission standards.

(5) The wastewater generated by thermal drying should be reused as a priority after treatment. When the wastewater is to be directly discharged into the water body, its water quality should be in line with the provisions of the Comprehensive Emission Standards for Sewage (GB 8978).

Anaerobic digestion.Anaerobic digestion is a very effective sludge treatment process that uses parthenogenic and anaerobic bacteria to carry out anaerobic biochemical reactions to decompose the organic substances in sludge and achieve sludge stabilisation.

(1) Land use disposal may be by anaerobic digestion of treated, compliant sludge products.

(2) Encourage the use of anaerobic digestion of sludge in urban domestic wastewater treatment plants, and the biogas produced should be comprehensively utilised.

(3) It is desirable to support the phosphorus recovery process unit to recover the phosphorus waste generated in the digested filtrate.

Aerobic composting.Aerobic composting usually refers to high-temperature aerobic fermentation, which is the process of converting organic matter in sludge into stable humus through the biological metabolism of aerobic microorganisms.

(1) Land use can be aerobic composting treatment of sludge products up to standard, when there is no land use pathway, aerobic composting treatment of sludge up to standard can be sanitary landfill or incineration.

(2) The sludge from urban domestic sewage treatment plant should be sufficiently dewatered to meet the composting water content requirements. The initial water content of mixed sludge should be 55%-65%, and the water content can be adjusted by adding fluffing agent and remixing dry sludge according to the actual situation.

(3) Composting can be done in the form of strip composting and bin (reactor) composting, of which the strip composting can be done in the form of static pile or turning pile. Static pile type stack composting should be equipped with ventilation and aeration facilities, fan operation can be used in the heap of air and heap suction in two forms. When the heap suction wind, leachate and concentrated liquid collection facilities should be set up in front of the fan and processed. Turning type strip pile compost should adopt special turning equipment, and it is preferable to turn the pile 3-4 times per week.

Silo composting can be in the form of Dano rotor, mechanical drum, vertical fermenter, tunnel fermenter, etc. It is desirable to use special facilities and equipment, and it is desirable to install automatic monitoring facilities.

(4) Encourage the use of garden waste such as cuttings, fallen leaves and agricultural waste such as huller, hulls and straw as auxiliary fillers added by high temperature aerobic fermentation.

(5) The ground and periphery of the sludge reception area, rapid reaction area, maturation area and storage area and the carriageway shall be impermeable. The whole process should be carried out on the ground after anti-seepage treatment.

(6) The composting plant shall set up facilities for the collection, removal and treatment of wastewater and construct a drainage system that separates rainwater and sewage.

(7) Odour control facilities shall be provided at the composting plant.

Vermiculture treatment.Vermiculture treatment usually involves mixing sludge with agricultural waste for fermentation pre-treatment and then adding it to the vermiculture beds, where it is digested by earthworms through feeding and converting the sludge into vermicompost to produce two products, earthworms and vermicompost.

(1) Vermiculture treatment projects should strictly implement the environmental impact assessment and approval system.

(2) There is no relevant industry standard for vermiculture sludge treatment, and the product vermicompost should meet the corresponding mud quality standards, and is suitable for land use.

(3) Sludge should be mixed and fermented with straw, mushroom residue, fruit and vegetable residues and other agricultural wastes as breeding substrate. The moisture content of the substrate should be kept above 65% during earthworm farming.

(4) It is desirable to use automated equipment for humidity control, nutrient solution feeding, earthworm sieving and other processes.

(5) The floor of the sludge earthworm farming area should be impermeable. The entire farming process should be carried out on the ground after impermeable treatment.

(6) Sludge vermiculture areas should be equipped with facilities for collecting, removing and treating wastewater, and building a drainage system that separates rainwater and sewage.

(7) Odour control facilities shall be provided in sludge vermiculture areas.

Other treatments.Sludge treatment units also include sludge pyrolysis, sludge carbonisation, supercritical water oxidation, etc. The use of new technologies should be subject to full techno-economic analysis.

Sludge transit and storage.Where sludge transfer stations and storage facilities need to be set up, they may refer to the Standard for the Setting of Urban Environmental Sanitation Facilities (CJJ27) and other regulations, and be approved by the relevant competent authorities before they are constructed and used.

The sludge treatment and disposal operation unit shall strictly implement relevant national laws and regulations on work safety and management provisions, and implement the work safety responsibility system; it shall implement relevant national occupational health standards and norms, and ensure the health of employees; it shall formulate relevant emergency response and disposal plans, and prevent accidents endangering public safety from occurring.

Sludge treatment and disposal units shall establish a complete system of testing, recording, archiving and reporting, and track, record and report on the destination, use and dosage of treated and disposed sludge and its by-products (sludge products), with the relevant information kept for at least five years.

Relevant local authorities shall, in accordance with their respective division of responsibilities, supervise and manage sludge land use, building materials use and other disposal methods. The sludge land use units shall entrust third-party organisations with relevant qualifications to regularly evaluate the changes in the environmental quality conditions after the land use of sludge products. Sludge treatment and disposal sites shall prohibit the keeping of domestic animals and poultry.

The competent authorities in charge of urban environmental sanitation should strengthen the supervision and management of landfills and incineration plants for sludge disposal. Landfill operating units receiving sludge shall, in accordance with relevant national standards and norms, regularly monitor the quality of sludge, the background value of water, gas and soil at the landfill site and the impact of operations. The sludge incineration operation unit shall, in accordance with relevant national standards and norms, regularly monitor the sludge nature, sludge volume, discharged wastewater, flue gas, slag, fly ash and so on. Sludge building materials comprehensive utilisation units are also required to monitor and record the nature and quantity of sludge products.

Governments at all levels should increase financial investment in the construction of sludge treatment and disposal facilities, and give financial and tax incentives in accordance with regulations for the inclusion of sludge treatment and disposal technologies and equipment that the State encourages the development of; establish a diversified investment and operation mechanism, and encourage the participation of social funds in the construction and operation of sludge treatment and disposal facilities through various means, such as franchising.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses