Filter press as a widely used in solid-liquid separation equipment, its water washing pressure requirements is an important parameter to pay attention to in the process of use. Water washing is an important part of the working process of the filter press, which is important for ensuring the normal operation of the equipment and the use of results. This article will focus on the filter press water washing pressure requirements for discussion, to help readers understand the relevant knowledge of this industry.

I. The role and importance of filter press water washing

Filter press water washing refers to flushing the filter cloth through a certain water pressure during the working process of the filter press, in order to remove the residual materials and dirt on the surface of the filter cloth. The role of water washing is to maintain the cleanliness of the filter cloth to prevent material clogging and bonding, so as to ensure the normal operation of the filter press and good filtration effect. Water washing can also extend the service life of the filter cloth and reduce equipment maintenance costs. Therefore, reasonable control of water washing pressure for the normal operation of the filter press is crucial.

II. Requirements for filter press water washing pressure

1. Pressure range

Filter press water washing pressure is generally required to be between 0.5-1.5Bar. The specific pressure range should be selected according to different models and specifications of the filter press and the actual working conditions. When selecting the washing pressure, the material, thickness, porosity and other factors of the filter cloth should be fully considered to ensure the washing effect and the durability of the filter cloth.

2. Pressure distribution

The water washing pressure should be evenly distributed on the surface of the filter cloth, in order to avoid the deformation or incomplete cleaning of the filter cloth caused by too high or too low local pressure. In order to ensure the uniformity of the water washing pressure, the wear and tear of the water washing nozzle should be checked regularly, and the badly worn nozzle should be replaced in time to maintain a reasonable distance between the nozzle and the surface of the filter cloth.

3. Pressure stability

Water washing pressure should be kept relatively stable, to avoid the sudden rise or fall of pressure on the filter cloth caused by the impact or poor cleaning effect. In order to ensure the stability of the water washing pressure, the water washing system should be regularly inspected and maintained, and the air and impurities in the system should be eliminated in time to ensure the smoothness of the pipeline and the normal operation of the pump.

Third, how to control the filter press water washing pressure

1. Monitoring and adjustment

To ensure the stability and effectiveness of the water washing pressure of the filter press, the water washing pressure should be monitored and adjusted in real time. By installing equipment such as pressure sensors and pressure gauges, the change in water washing pressure can be monitored in real time, and the pressure can be adjusted according to actual needs. The sealing performance of the water washing system should be checked regularly to prevent leaks from causing pressure drops.

2. Regular maintenance and upkeep

In order to ensure the durability and reliability of the water washing pressure of the filter press, the water washing system should be regularly maintained and serviced. This includes cleaning or replacing the filter cloth, checking the wear and tear of the nozzles, cleaning the pipelines and water pumps, and so on. By finding and solving potential problems in time, the normal operation of the water washing system can be ensured and good water washing results can be maintained.

3. Operator training and regulation

The operator is one of the key factors in controlling the water washing pressure of the filter press. Professional training should be given to the operators to make them understand the requirements and control methods of water washing pressure, and to master the correct operation techniques and precautions. Standard operating procedures and precautions should be formulated, and the division of responsibilities should be clearly defined to ensure that the operators can operate and maintain in accordance with the requirements.

IV. Case studies and practical experience

In practical application, an enterprise adopts an intelligent filter press water washing system. The system realises real-time monitoring and adjustment of water washing pressure through automatic control technology, ensuring the stability and reliability of water washing effect. The enterprise also formulated a series of standardised operation and maintenance procedures, strengthened the training and management of operators, and improved the operational efficiency and reliability of the entire system. Through the implementation of these measures, the enterprise has successfully improved the filtration effect and service life of the filter press, and reduced maintenance and production costs.

Filter press water washing pressure requirement is one of the important factors to ensure the normal operation of the equipment and good filtration effect. In practical application, the water washing pressure should be reasonably selected and controlled to maintain the cleanliness and durability of the filter cloth. In order to achieve this goal, enterprises should strengthen the training and management of operators, and develop standardised operation and maintenance procedures; intelligent control systems should also be used to monitor and adjust the washing pressure in real time, in order to improve the operational efficiency and reliability of the whole system. In the future development, with the continuous progress of technology and application demand, the filter press and its water washing system will continue to innovate and improve to meet more extensive and diversified market demand. Therefore, it is recommended that the relevant enterprises and researchers continue to pay attention to the industry dynamics and technological development, strengthen cooperation and innovation, and promote the sustainable development of the filter press industry.

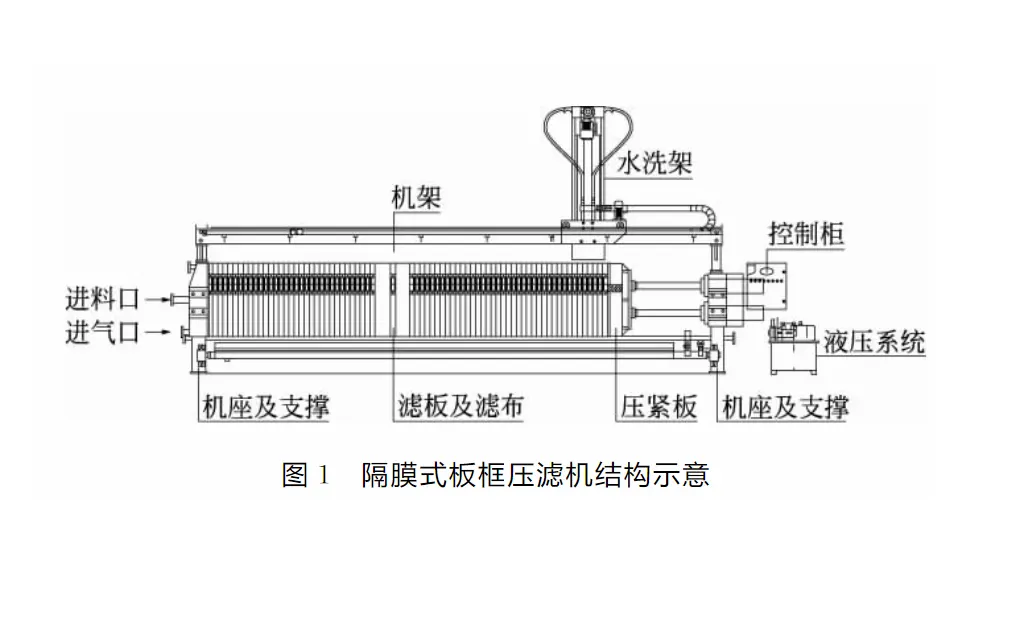

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses