introductory

Mechanisation and intelligent development make coal mining more and more efficient. Under the high intensity mining, the proportion of fine particles in the raw coal increases significantly, which brings many problems to the subsequent coal washing, especially in the recovery of fine coal slurry. Under the background of high-quality development of coal producers and strict environmental regulations, reasonable disposal of fine coal slurry has become an important challenge for coal enterprises. After years of technological development and application practice, a relatively mature coal slurry sorting technology system has been formed, and the commonly used coal slurry recovery process equipment includes: filter press, pressurised filter and sedimentation centrifuge. Filter press has strong adaptability to feed, high filtrate clarification, low operating costs, but the product moisture is high, occupies a large area; pressurised filters and sedimentation centrifuges have low product moisture, large single machine capacity, small area, high degree of automation, but the pressurised filter system is complex, high investment and operating costs, sedimentation centrifuges have a high lower limit of recycling, and the rotor needs to be regularly repaired. Three kinds of equipment have their own characteristics, have been widely used at home and abroad, in addition to single equipment recovery process, but also derived from "pressurised filtration + sedimentation centrifugation" "pressurised filtration + pressure filtration" "sedimentation centrifugation + pressure filtration The combined process of "pressurised filtration + sedimentation centrifugation", "pressurised filtration + filtration press" and so on. Only by combining the nature of coal slurry, the amount of coal slurry and plant space and other conditions to choose the appropriate coal slurry recycling equipment, technology in order to economically and efficiently recover coal slurry. In addition, the form of process arrangement is also a major problem of coal slurry disposal, especially for the space constraints of the project, the reasonable use of existing space arrangement process can save considerable costs for the enterprise. Bourdong Coal Processing Plant is newly set up in the existing mine industrial site, for its fine coal slurry with high moisture, high ash, low ignition point and other characteristics, as well as the characteristics of the existing industrial site is narrow and can not be new land, to explore the fine coal slurry recycling process selection and arrangement methods.

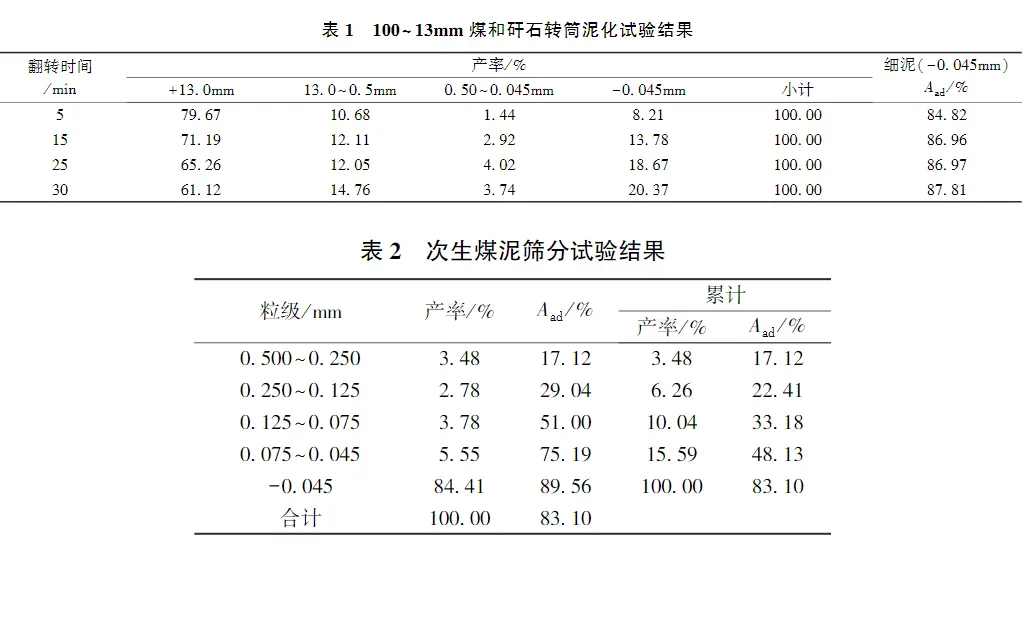

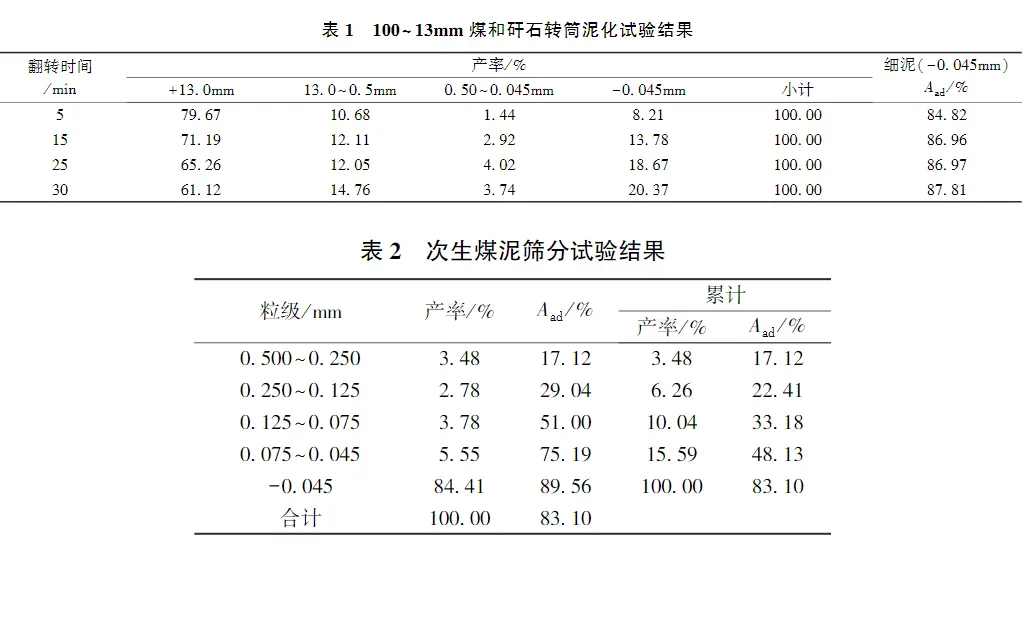

1 Raw coal quality characteristics and fine coal slurry characteristics of Bourdong Coal Mine Coal Processing Plant for power coal processing plant, Bourdong Coal Mine supporting coal processing plant, mainly into the selection of the mine's raw coal. Bourdong Coal Mine is located in Dongsheng Coal Field of Shendong Mining Area, with a production capacity of 2.4 million t/a. There are 4 seams in Bourdong Coal Mine, namely 4-1, 4-2 upper, 4-2 and 6-2 seams, of which 4-1, 4-2 upper and 4-2 seams are the stable seams that can be extracted for most of the area, and 6-2 seams are the stable seams that can be extracted for the whole area. The depth of these 4 seams is shallow, the structure of the seams is simple, and they do not contain or only contain a layer of interbedded gangue. The lithology of the top plate is mainly siltstone and sandy mudstone; the lithology of the bottom plate is mainly sandy mudstone, locally fine sandstone. The coal seams of this mine have low content of harmful components, low ash and sulphur content, and high calorific value, which is a good coal for civil and power use. In order to study the sludging characteristics of raw coal and the content of secondary sludge, the rotary sludging test of 100~13mm raw coal and the sieving test of secondary sludge were carried out respectively, and the results are shown in Tables 1 and 2. With the prolongation of turning time, the yield of raw coal with high granularity gradually decreases. With the prolongation of the overturning time, the yield of high granularity raw coal decreased gradually, the yield of secondary coal slurry increased gradually, and the specific gravity of -0.045mm granularity fine slurry was higher and the ash content increased gradually, which indicated that the coal quality was hard and easy to be crushed, and the phenomenon of raw coal sludging was more serious. In the secondary coal slurry, the ash content of each particle size increases with the decrease of particle size, -0.25mm slurry content reaches 96.52%, -0.045mm fine slurry yield is 84.41%, and the ash content is as high as 89.56%, which seriously affects the settling of coal slurry water and increases the difficulty of the treatment of coal slurry water. Therefore, in the design, we must take into full consideration of the characteristics of the original coal with serious sludging and fine mud, and reasonably select the fine sludge recycling process and process arrangement.

2 fine coal sludge recycling treatment process selection of the current application of more power coal beneficiation plant fine coal sludge recycling process are: filter press alone recycling process, pressurised filter alone recycling process, "pressurised filter + filter press" two-stage recycling process, "screen settling centrifuge + filter press Two-stage recycling process of "screen settling centrifuge + filter press".

1) Filter press separate recycling process. Filter press can realise clear water in one press, and it is the ideal gatekeeper for the closed circuit recycling of washing water in coal beneficiation plant. This process is suitable for all power coal processing plants, especially for coal slurry content is small, and the content of fine-grained slurry in the coal slurry is more, it is the ideal process for the fine slurry dewatering and recycling system of the coal processing plant with more serious mud phenomenon.

2) Pressurised filter separate recovery process. Pressurised filter has the advantages of good dewatering effect, large processing capacity, and loose and easy mixing of filtered products. This process is suitable for coal slurry content is larger, less fine sludge content of the coal processing plant, while requiring a higher degree of automation of the washing process, and the use of pressurised filters to do the industrial test is better, or in the same mine to deal with the same type of coal when the effect is more pronounced in the coal processing plant. Pressurised filter feed in general -0.045mm particle content is less than 40%, coal slurry recovery effect is better, for the serious mud, fine-grained material content is higher in the coal plant, because of its high content of fine-grained materials, will lead to pressurised filter capacity is greatly reduced, and even equipment can not operate normally.

3) "Pressurised filter + filter press" two-stage recovery process. This process adopts one section of pressurised filter to recover one section of bottom stream coarse coal slurry with +0.045mm particle size, and two sections of diaphragm filter press to recover two sections of bottom stream fine coal slurry with -0.045mm particle size. It is suitable for the coal processing plant which is difficult to settle coal slurry at one time, and the content of +0.045mm particle size coarse coal slurry is higher, and the effect of pressurised filter is good, and at the same time it requires the moisture content to be low.

4) "Screen sedimentation centrifuge + filter press" separate recovery process. This process adopts one section of screen sedimentation centrifuge to recover one section of bottom stream coarse coal slurry with +0.045mm particle size, and two sections of diaphragm filter press to recover two sections of bottom stream fine coal slurry with -0.045mm particle size, which is suitable for coal slurry with more difficulty in one-time sedimentation, high content of +0.045mm particle size coarse coal slurry, and less than 20% of fine coal slurry, and the raw coal is not sludged or the phenomenon of sludging is not serious. The coal processing plant of Bourdong Coal Mine is a serious coal processing plant. As the coal quality of Bourdong coal processing plant is more serious, the content of +0.045mm particle size in the coal slurry is not high, only 15.59%; and the content of -0.045mm is very high, up to 84.41%, so it is not suitable to use pressurised filter and screen centrifuge for recovery, and it is not suitable to use two-stage recovery. Through the above analyses, it was finally determined that the fine coal sludge recycling in this plant adopts the separate recycling process of filter press.

3 process layout selection filter press recovery system process layout is mainly related to the coal slurry product direction, general plan location, concentration workshop location and coal slurry drying field location and other factors. There are mainly the following layout forms: 1) Filter press recovery system, coal slurry drying field centralised layout. The filter press recovery system is arranged separately in the filter press workshop and centrally arranged with the coal slurry drying field. Filter press workshop is arranged in two floors, the first floor is arranged with feeding mixing barrel and filter press, the ground floor is partly arranged with feeding pumps and other equipments, and partly as a coal slurry landing site; the coal slurry drying field is arranged in the ground floor. The process is that the coal slurry discharged from the filter press pulling plate falls directly to the ground buffer pile on the ground floor, and is shovelled into the coal slurry drying field by shovel to dry naturally and then transported out. This arrangement form is suitable for industrial site location restrictions, the main plant around the site is not enough, and there is no filter press workshop, coal slurry drying field separate layout site; raw coal quality is poor, filter press dewatering effect is poor, coal slurry moisture, ash are high, low calorific value, it is not suitable for direct mixing into the final coal products; coal slurry moisture content is too high, is not suitable for the tape transshipment; coal slurry ignition point is low, it is not suitable for drying and precipitation; drying coal slurry. The cost is too high, there is no economic benefit of coal processing plant.

2) Filter press recovery system and coal slurry drying yard are arranged separately. The filter press recovery system is arranged separately in the filter press workshop, and the coal slurry drying yard is arranged separately. The filter press workshop is arranged in two layers, the second layer is arranged with feed mixing barrel and filter press, the first layer is partly arranged with feed pump, filtrate pump, coal slurry collecting scraper and transferring belt conveyor, etc. The coal slurry drying yard is arranged according to the closed coal slurry drying yard. The coal slurry drying yard is set up according to the closed coal shed. The process flow is that the coal sludge unloaded from the pulling plate of the filter press falls directly to the collecting scraper on the ground floor, feeds to the transferring belt conveyor, and then is transported to the coal sludge drying yard for unloading and stacking, and then is naturally dried or dried and transported out. This arrangement form is suitable for industrial site location restrictions, insufficient space around the main plant, filter press workshop, coal slurry drying field can not be centrally arranged; raw coal quality is poor, the effect of filter press dewatering is poor, slurry moisture, ash are high, low calorific value, it is not suitable for direct blending into the final coal products; coal slurry drying field needs to be arranged in the drying facilities of the coal preparation plant.

3) Filter press recovery system, main plant and coal slurry drying yard are centrally arranged as a whole. Filter press recovery system and coal sludge drying yard are arranged in one side of the main plant, with two layers, the second layer is arranged with feeding mixing drum and filter press, the first layer is partly arranged with feeding pump and other equipment, and partly as a coal sludge landing site; the coal sludge drying yard is arranged on one layer. The process is that the coal slurry discharged from the filter press pulling plate directly falls to the ground buffer pile on the ground floor, and is shovelled into the coal slurry drying field by shovel to dry naturally and then transported out. This arrangement form is suitable for the industrial site is flat and spacious, convenient for centralised arrangement; the raw coal quality is poor, the effect of filtering and dewatering is poor, the moisture and ash content of coal slurry are high, the heat content is low, it is not suitable for directly mixing into the final coal products; the one-piece arrangement meets the requirements of fire protection partition; the moisture content of coal slurry is too high, it is not suitable for the tape reproduction; the burning point of coal slurry is low, it is not suitable for drying and descaling; the cost of drying coal slurry is too high, it does not have economic benefits. Coal processing plant.

4) The filter press recovery system and the main plant are centrally arranged as a whole, and the coal slurry drying yard is arranged separately. Filter press recovery system is arranged in one side of the main plant, with two layers, the second layer is arranged with feed mixing barrel and filter press, the first layer is arranged with feed pump, filtrate pump, coal slurry collection scraper and transfer belt conveyor. The coal slurry drying yard is set up according to the closed coal shed. The process flow is that the coal slurry unloaded from the pulling plate of the filter press falls directly to the collecting scraper on the ground floor, and then feeds to the transferring belt conveyor, and is transported to the coal slurry drying yard for unloading and stacking, and then is naturally dried or dried in the coal slurry drying yard for external transport. This arrangement form is one of the most commonly used arrangement forms for power coal processing plant. This arrangement form is suitable for the industrial site is flat and spacious, the space location is rich; the raw coal quality is poor, the effect of filtering and dewatering is poor, the moisture and ash content of coal slurry are on the high side, the calorific value is low, it is not suitable to be directly mixed into the final coal products; the coal slurry drying field needs to be arranged with drying facilities of the coal beneficiation plant.

5) Filter press recovery system is arranged separately, and the coal slurry is blended back into the final coal products. Filter press recovery system is arranged separately in the filter press workshop, which is arranged in two layers, the second layer is arranged with feed mixing drum and filter press, and the first layer is arranged with feed pumps, filtrate pumps, coal slurry collection scraper and transfer belt conveyor, etc. The process is that the coal slurry discharged from the pulling plate of the filter press falls directly to the collection scraper, and then feeds to the transfer belt conveyor. The process flow is that the coal slurry discharged from the filter press pulling plate falls directly to the first layer of collection scraper, and then feeds to the reproduction belt conveyor, and is transported to the end of the coal product belt conveyor for blending into the silo. This arrangement form is suitable for industrial site location restrictions, the main plant is not enough space around the main plant, the filter press workshop can not be centrally arranged with the main plant; the raw coal quality is good, the filter press dewatering effect is good, the coal slurry has a high calorific value and is suitable for blending into the final coal products; the integrated arrangement with the main plant can not meet the requirements of the fire protection zoning, and only a separate arrangement can meet the requirements of the fire protection of the coal processing plant.

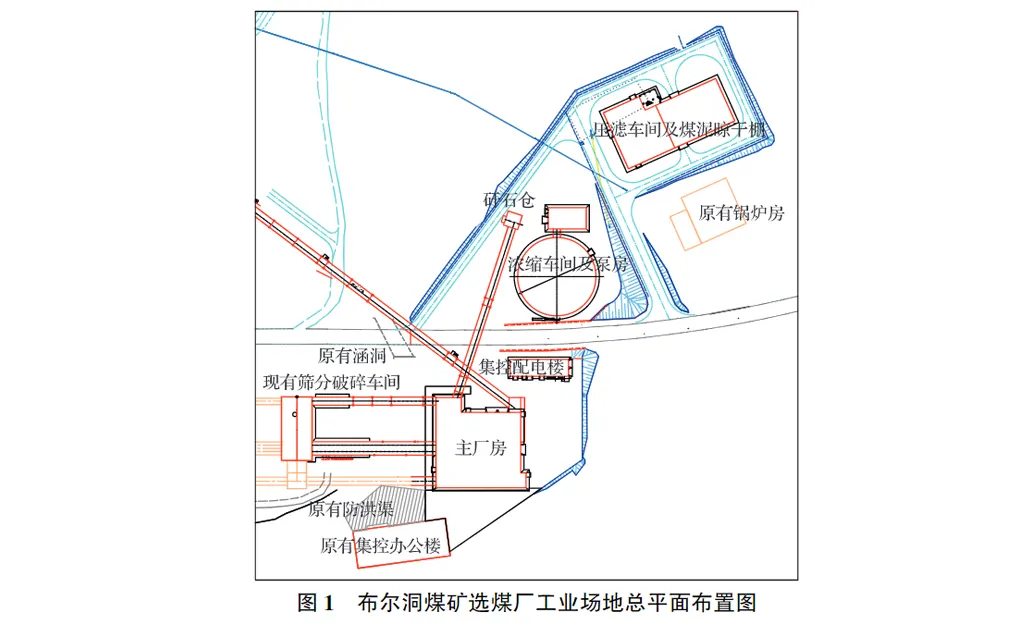

6) Filter press recovery system is centrally arranged with the main plant, and the coal slurry is blended back into the final coal products. Filter press recovery system is arranged in one side of the main plant, with two layers, the second layer is arranged with feed mixing drum and filter press, the first layer is partly arranged with feed pump, filtrate pump, coal slurry collection scraper and reproduction belt conveyor, etc. The process is that the coal slurry unloaded from the pull plate of the filter press falls directly to the collection scraper and reproduction belt conveyor. The process flow is that the coal slurry unloaded from the filter press pulling plate falls directly to the first layer of collection scraper, and then feeds to the reproduction belt conveyor, and is transported to the main plant for blending into the silo on the belt conveyor of the final coal products. This arrangement is also one of the most commonly used arrangement forms in power coal processing plants. This arrangement is suitable for the coal processing plant with flat and spacious industrial site, rich space location; good quality of raw coal, good dewatering effect of filter press, high heat content of coal slurry, which is suitable for blending into the final coal products; and the integrated arrangement with the main plant to meet the requirements of fire protection zoning. By comparing the six process arrangement forms of the filter press recovery system, combined with the general layout of the industrial site of the coal processing plant in Bourdong Coal Mine, as shown in Figure 1.

It can be seen that Bourdong coal processing plant is in the existing mine industrial site new arrangement, the existing industrial site is narrow, the remaining space is small and scattered, can not be newly purchased land, the main plant around the site is not enough, so there is no filter press workshop, coal slurry drying field separate layout site, coal slurry low ignition point is not suitable for drying and precipitation, fine coal slurry in the high-density material kaolin content is more high moisture, combined with the neighbourhood of the actual production of coal plant Combined with the actual production experience of neighbouring coal processing plants, the belt conveyor transport is easy to slip, and the ash content is high, which is not suitable for the coal slurry directly back to mixing the final coal product layout form, so the fine coal slurry recycling system of this coal processing plant is arranged in the form of a centralised integrated arrangement of the filter-pressing and recycling system and the coal slurry drying field.

4 Conclusion

1)The content of fine coal slurry is high in the coal processing plant of Bourdong coal mine, and the raw coal is easy to be sludged, so it is suitable to use the filter press recovery process to recover the fine coal slurry.

2)The fine coal slurry of Boerdong coal mine coal processing plant has the characteristics of high moisture, high ash, low ignition point, etc., the existing industrial site is narrow, the remaining space is small and scattered, and it is not possible to add new land, therefore, the fine coal slurry recycling system of the plant is arranged in the form of filter-pressing and recycling system, and the slurry drying field is centrally arranged in the form of a single unit, which not only can make full use of the existing site space and improve the competitiveness of the final coal products, but also can create good economic benefits for the coal processing plant. economic benefits for the coal processing plant.

Welcome to call us for consultation, technical exchange, and material experiment.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses