With the large-scale construction of urban sewage treatment plants in China, the sludge produced by them has become a new source of environmental pollution, and these sludges have high water content and other problems, so the deep dewatering of these sludges has become one of the key research topics. It is found that the deep dewatering of sludge by chamber diaphragm filter press after pharmaceutical modification of municipal sludge can form sludge cake with low water content and achieve sludge reduction. In this paper, the sludge filtration process and filtration characteristics of chamber diaphragm filter press were studied in depth by combining simulation and experiment. The main work is as follows:

1. Establishment of compartmentsdiaphragm filter pressThe physical model of a single filter chamber, in the CFD simulation software Fluent using the standard seven-one-occupancy model, mixing model, porous media model, etc. to establish the mathematical model of the sludge solid-liquid two-phase flow field within a single filter chamber, to provide conditions for the simulation of solid-liquid two-phase flow simulation, the application of the model established above on the solid-liquid two-phase flow field within the chamber of the compartment-type diaphragm filter press single velocity distribution, pressure distribution, concentration distribution, etc. to carry out simulation. Simulation was carried out to obtain the change law of pressure drop at both ends of the cake, the formation law of the cake and the basic flow law of two-phase flow of sludge in the filter chamber;

3. Simulation analysis under different filtration pressures. Studied the velocity distribution in the filter chamber under different filtration pressures and the change rule of the water content of the filter cake;

4. Simulation analysis under different feeding methods. Comparing the sludge feeding method from the centre of the filter chamber with that from the upper part of the chamber to study the cake formation pattern and the uniformity of the formed cake, the results show that the sludge feeding method from the centre of the filter chamber is better than that from the upper part of the filter chamber;

5. Determination of optimal chamber thickness. The water content of the filter cake formed under different filter chamber thicknesses and the production rate of the filter cake per unit time were studied, and the optimum filter chamber thickness of 12mm was found in the comprehensive analysis of this research model;

6. Experiment on the filtration performance of the chamber diaphragm filter press and compare the experimental results with the simulation results, and find that the maximum error is within 10%, which verifies the correctness of the simulation results; through the termination of the feed and then carry out the press dewatering treatment, so that the water content of the cake is further reduced, and at the same time, this process has found a suitable starting point for the press. The results can be used to guide the design and use of chamber diaphragm filter presses.

Keywords: chamber diaphragm filter press; cake water content; numerical simulation; filtration pressure; filter chamber

Abstract: lm the large.scale construction of urban sewage treatment plant in our COUlltry,sludge generated has become a new source of environmental pollution, which have a high moisture content sludge and other issues, SO the depth of the sludge dewatering become one of these key research topics. 111e study found that when the agents modified of urban sludge finished, the sludge generated by the sludge dewatering process will be more efficient. study found that when the agents modified of urban sludge finished, sludge dewatering depth by Van membrane filter press sludge Can form cake with low In this paper,sludge filtration process and filter characteristics of filtration chamber in Van membrane filter press were studied by the method. In this paper,sludge filtration process and filter characteristics of filtration chamber in Van membrane filter press were studied by the method of the numerical simulation combined with experimental validation.The main work is as follows: Firstly The main work is as follows: Firstly, the paper establishes the physical model of single filtration chamber in Van membrane filter press.within fluent of the FLUENT simulation software. Firstly ,the paper establishes the physical model of single filtration chamber in Van membrane filter press. within fluent of the FLUENT simulation software, using the standard k-s model, hybrid model and porous media models, the mathematical model of the solid-liquid two. filtration chamber of Van membrane filter press has been built, which provided the conditions for the solid-liquid two-phase flow numerical simulation. Secondly, application of the above physical and mathematical models, speed distribution, pressure distribution, concentration field distribution, and the distribution of the two-phase flow field of Van membrane filter press have been built, which provided the conditions for the solid-liquid two-phase flow numerical simulation. in two-phase flow field of single filtration chamber in Van membrane filter press have simulated and got the changes law in pressure drop across the filter The two-phase flow field of single filtration chamber in Van membrane filter press have simulated and got the changes law in pressure drop across the filter cake, analysed the pattern of filter cake was formed and the basic flow law of sludge two-phase field in filtration chamber, etc.; Thirdly, simulation analysis under different filtration Thirdly, simulation analysis under different filtration pressures. studing the law of velocity distribution and the moisture content of cake formed under different filtration pressure. Thirdly, simulation analysis under different filtration pressures. studing the law of velocity distribution and the moisture content of cake formed under different filtration pressure; Fourthly, simulation analysis under different feeding methods. Comparison of sludge from the filter chamber centre feeding mode and the upper feeding mode, studying the formation of the cake and the uniformity of cake formed.The results show that the centre feed way is FifHl, determine the optimum thickness of filter chamber. studying the moisture content of cake formed and the cake volume yield per unit of time under different thickness of the filter chamber, comprehensive analysis to select 1 2ram as the best filter chamber thickness of the filter chamber. yield per unit of time under different thickness of the filter chamber,comprehensive analysis to select 1 2ram as the best filter chamber thickness of the research modle. research modle; Sixth, Filter performance test is taken on Van membrane filter press, experimental results obtained are compared with the simulation results, the maximum error iS less than 1 0%, to verify the correctness of the simulation; squeeze dewatering after feed finished, SO further reducing the moisture content of the cake, by experiment to find the right time as the press start point.T]. search results l research Can guide guide th,de: "g the desima and use of the vailIllS membrane fiiter press. this article has forty This article has forty-one pictures, seven tables, seventy-one references.

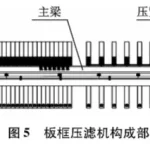

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses