500平方Plate and frame filter pressTechnical parameters::

用于各种悬浮物料固液分离提高分离效 率、降低滤饼含水率的理想设备。广泛应用于石油、化工、印染、冶金、医药、食品、纺织、电 镀、造纸及城市生活污水处理等行业的各种固液分离领域。

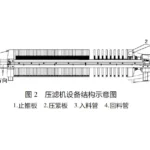

压滤机采用机、电、仪一体化设计制造,能根据用 户的需求, 实现滤板液压压紧、自动保压、过滤、压榨、吹气、洗涤、滤板松开、卸料等工序的 自动化控制。该机型配置了隔膜板, 进料过滤后, 通过水压或气压的方式改变滤室容积,对滤饼进行压榨, 进一步降低含水率。过滤板和隔膜压榨板采用优质增强聚丙烯复合材料模压成型,具有机械强度高、化学性能稳定, 耐酸、耐碱、抗老化、无毒、无味、坚固耐用; 电器元件和液压 元件均采用名牌厂家产品,使用寿命长;机架采用优质钢板焊接而成,强度高、经久耐用。

This series of filter presses implement the standard: JB/T4333-2005 "chamber filter press technical conditions".

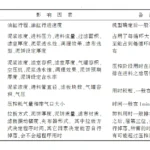

| 名 称 | 参 数 | 名 称 | 参 数 |

| Working filtration pressure | ≤0.6MPa | Temperature resistance of filter plate | 0-70°C |

| 最大液压保护压力 | 25MPa | 滤饼厚度(压榨前/后 | 28-30/20-25mm |

| Compacting working pressure | 16-20MPa | valid itinerary | 800mm |

| Filter plate acid and alkali resistance | 2<PH<12 | 过滤板/隔膜板厚度 | 1500×1500×80/85 |

| Diaphragm Pressure | 0.8-1.2MPa(根据用户要求可另行设计压榨压力最大达 1.6 或 2.0MPa) | ||

主要参数:

| Specification | filter plate 付数(付) | 滤室容积(m3) | 外形尺寸(mm) | 滤布规格(mm) | 配用power (output)(KW) | 单机重量(Kg) | |||

| 长 | 宽 | your (honorific) | 长 | 宽 | |||||

|

X(A/M)200/1500-U |

26 | 3.00 | 7660 |

2400 |

2020 |

3200 |

1580 |

11.5KW |

21100 |

| X(A/M)220/1500-U | 29 | 3.30 | 8160 | 22000 | |||||

| X(A/M)250/1500-U | 32 | 3.75 | 8650 | 23200 | |||||

| X(A/M)280/1500-U | 36 | 4.20 | 9310 | 24500 | |||||

| X(A/M)300/1500-U | 38 | 4.50 | 9640 | 25300 | |||||

| X(A/M)320/1500-U | 41 | 4.80 | 10640 | 26500 | |||||

| X(A/M)340/1500-U | 44 | 5.10 | 11140 | 27500 | |||||

| X(A/M)350/1500-U | 45 | 5.30 | 11300 | 27800 | |||||

| X(A/M)400/1500-U | 51 | 6.00 | 12290 | 29500 | |||||

| X(A/M)450/1500-U | 58 | 6.75 | 13450 | 31200 | |||||

| X(A/M)500/1500-U | 64 | 7.50 | 14440 | 33200 | |||||

The final explanation of this product belongs to su-ton and is subject to change without prior notice.

下单请联系我们销售人员,谢谢!

500平方板框压滤机技术参数及更多压滤机参考数据可查阅以下表格:

Disclaimer: The copyright of this article belongs to the original author and the original source. Welcome to call us for consultation, technical exchanges, and material experiments.

Enquiry: 188517-18517

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses