introductory

Coal Preparation Plant Filter PressDesigned by Jinan Design & Research Institute of Coal Industry, it is a centre coal processing plant with a capacity of 1.2Mt/a. The plant is located in Xiaojiazhuang Township Industrial Park, Chiping County, Liaocheng City. The main production processes are: +50mm lump coal check hand sorting, 50-0.5mm raw coal unpressurised three-product heavy media cyclone sorting, -0.5mm slurry flotation, tailings filter-drying and recycling. Raw coal classification screen, crusher, unpressurised three-product heavy-duty cyclone, de-ballasted sieve, centrifuge, magnetic separator, flotation machine, thickener and filter press, etc. are all domestic advanced and reliable equipments.

1 Overview of coal preparation plant design

1.1 Coal Quality and Product Positioning Coal beneficiation plant's coal source is mainly purchased from outside and transported by car. The washed raw coal is mainly purchased from Xinjiang Hami area and Shanxi Changzhi area, and the coal type is mainly 1/3 coking coal. After washing and processing, the refined coal can be used as coking coal. Designed to determine the leading products of coal plant for high quality coking coal, coal ash <8.5%, water <10%, washed coal ash <40%, water 5000kcal/kg, coal slurry ash >50%, after drying, and washed coal is sold as power coal. Gangue ash>85% is used as raw material for local building materials factory. Coal blending is mainly purchased from Yulin area in Shaanxi Province, and the coal type is poor coal and non-stick coal, which can be sold as separate coal blending or blended with washed coal of the coal preparation plant as power coal. Ash <30%, Moisture 5500kcal/kg.

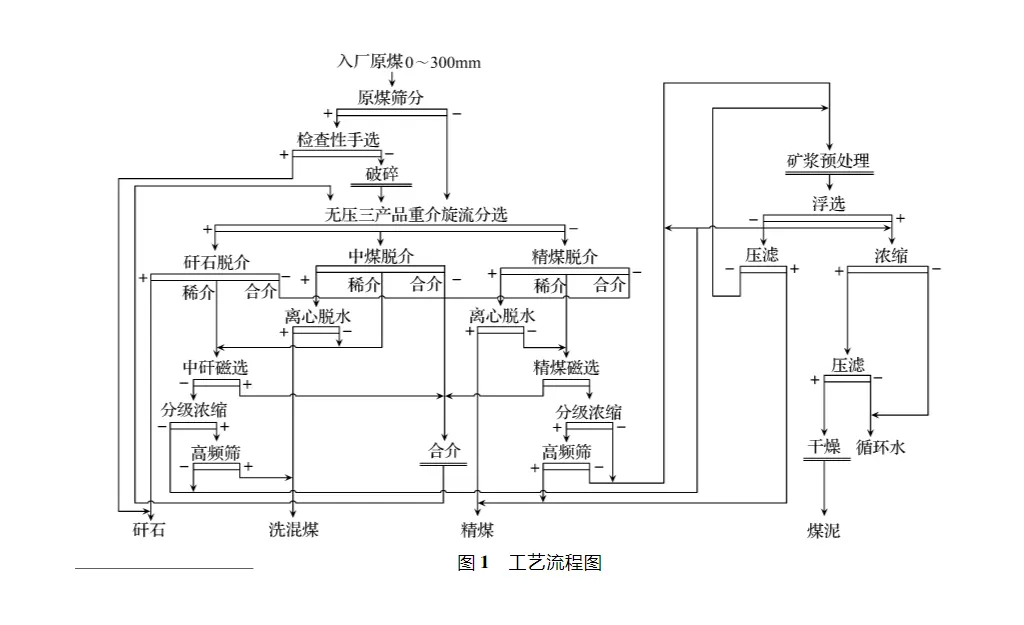

1.2 Process Flow of Coal Preparation Plant The process flow of coal preparation plant is shown in Figure 1. The process mainly includes: +50mm lump coal checking hand-selection, 50 ~ 0.5mm raw coal without pressure three products of heavy media cyclone sorting, -0.5mm coal slurry flotation, tailings concentration filter press recovery.

2 Coal Processing Plant Main Plant Arrangement

2.1 The main plant adopts a modular, hall-type layout and reinforced concrete structure, and is built jointly with the screening and crushing workshop, filter press workshop and media warehouse. It has the features of simple and flexible system, high efficiency, low investment, convenient equipment inspection and repair, high automation level and small labour force. The main body is three-storey, partially four-storey, with good lighting, ventilation and vision. Inside the plant, there are raw coal classification screen, lump coal crusher, pressureless three-product heavy-duty cyclone, de-dielectric vibrating screen, all kinds of media barrels, pumps, centrifuges, as well as thickening and grading cyclone, flotation machine,Fine Coal Filter PressThe plant is equipped with a 16t electric single girder crane on the top of the plant, which is convenient for installation and maintenance of the equipment, tailing coal filter press and product transport equipment. A 16t electric single girder crane is installed on the top of the plant, which is convenient for equipment installation and maintenance.

2.2 Thickener workshop The thickener workshop is equipped with two Φ30m thickeners as well as a pump room, a recirculation pool, and a clean water pool, etc. One thickener is used as an accident thickener. One of the thickeners is used as an accident thickener. The pump house is a two-storey semi-underground concrete structure, and a 5t electric hoist is installed on the top of the pump house, which can meet the requirements for lifting and replacing the equipment inside the pump house.

3 Design feature analysis

3.1 The sorting system and coal blending method are adaptable, flexible and reliable, and the coal source of the coal preparation plant is mainly purchased. The design of the plant is based on the characteristics of the purchased raw coal with large differences in coal type and coal quality, and realises the function of coal blending and separate separation, so as to ensure the best use of the coal, realise the high quality of the products, and maximise the added value of the raw coal. The washed raw coal mainly consists of 1/3 coking coal, and its leading product market positioning is high-quality coking coal. In view of the characteristics of large changes in the amount of coal slurry, the design recommends the use of a combined separation process of 50-0.5mm non-pressurised three-product heavy media cyclone separation, -0.5mm coal slurry flotation, and tailing filter recovery, which is an advanced process, adaptable to different coal qualities, flexible and reliable, and the washed water of the plant has reached the first level of closed-circuit recycling. The coal blending of power coal is mainly based on poor coal and non-sticky coal. According to the calorific value of the final product, the coal with different calorific value is quantitatively fed into the belt conveyor into the mixing and crushing station by using the quantitative coal feeder under the receiving pit, and then it is stirred evenly and stored in the coal blending product warehouse. Coal blending products and coal slurry can also be sold after drying in the coal preparation plant. The coal blending system is flexible, reliable and has strong ability to adapt to the market.

3.2 Optimise the design of coal storage yard to achieve homogeneous coal allocation According to the different types and uses of coal, a total of 6 coal storage yards are set up at the site, with the capacity of each storage yard from 1# to 3# of about 15,000t, and that of each storage yard from 4# to 6# of about 30,000t. The raw coal to be selected enters into the storage yards of 4# to 6# through the spiral unloader and is fed into the selecting belt conveyor into the main plant washing through the under feeder of the receiving pit. The incoming raw coal enters the 4#~6# storage yard through the screw unloader, and is fed into the incoming belt conveyor through the under-pit coal feeder to enter the main plant for washing. Coal blending enters 1#~3# coal storage yard through screw unloader, and is fed into the mixing and crushing station through the quantitative coal feeder under the receiving pit, and then it is stirred uniformly and sold in the coal blending product warehouse. Coal storage shed is set up in the coal storage yard, with steel column-steel mesh frame structure, surrounded by windproof and dust-suppressing mesh, meeting the environmental protection requirements, and the turnover capacity of coal storage is about 1.50Mt/a.

3.3 Optimisation of product metering method: 4 Φ18m silos are set up in the plant, each with a capacity of 5,000t, one of which is used as a concentrate silo in the plant, and the other three are used as a batching silo. Two sets of 150t truck weigher are set up under each silo, and there are 8 sets in total, which are used for the measurement of exported product coal, to realise the function of product pre-measurement, avoid overloading and reversing, etc., and realise the quantitative loading of product under the silo.

3.4 Simple modular workshop arrangement The main plant of the coal processing plant adopts a hall-type arrangement, and a 16t single girder electric crane is used on the top to complete the lifting, installation and maintenance of the main equipment in the workshop, which saves the maintenance space and lifting equipment to the maximum extent. The simple modular arrangement of the workshop achieves the maximum utilisation of the building space.

3.5 The general layout is reasonable, with clear functional zoning, compact and reasonable layout, and convenient transport routes. It is divided into the following three areas: operation area: located in the middle and northern part of the site, this area is the core working area of the whole coal preparation plant, which is responsible for unloading, storage and transportation of foreign coal, coal distribution, washing, and the overall replacement of metering, which is extremely convenient.

4 Analysis of design features The process flow of the new Taoyang Coal Processing Plant is characterised by reasonable design, advanced technology, reliable system and convenient management.

1) Advanced and reliable process and link settings. The design adopts advanced pressure-free three-product heavy media cyclone sorting technology, which greatly improves the sorting precision and sorting efficiency. Adopting TBS coal slurry sorting machine can effectively recover coarse and fine coal slurry and improve the recovery rate of fine coal.

2) the main equipment advanced technology, reliable production, to ensure the sorting, classification, dehydration, de-mediation effect, to ensure that the system is reliable and efficient; the process equipment close connection, production management is convenient.

3) Raw coal sorting, product dewatering, media recycling, coarse slurry sorting and recycling are all adopted in self-flow mode, with fewer intermediate links, compact layout, space-saving, and reduced energy consumption.

4) The ground process layout is reasonable, simple and clean, with clear functional zoning, full consideration of the use of existing facilities, which not only meets the requirements of safe production of coal preparation plant, but also reduces the construction investment.

5 Conclusion The design of the new Taoyang Coal Processing Plant takes into full consideration of the characteristics of the coal quality of the mine and the market demand, with appropriate coal processing methods, advanced process flow, advanced equipment selection, reasonable product structure, compact layout, convenient management, reflecting the latest concepts of the design, and in line with the overall requirements of coal processing and utilisation. The coal processing plant was put into operation in May 2012 after one month of debugging, and was formally put into operation in June, and has been operating normally with all the indexes meeting the design requirements.

Disclaimer: The copyright of this article belongs to the original author and the original source. Welcome to call us for consultation, technical exchanges, and material experiments.

Enquiry: 188517-18517

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses