introductory

机械化、智能化发展使得煤炭开采愈加高效。在高强度开采下,原煤中的细颗粒占比显著升高,给后续煤炭洗选带来诸多问题,在细煤泥回收中尤为凸显。煤炭生产企业高质量发展、环境规制趋于严格的背景下,合理处置细粒煤泥成为煤炭企业面临着重要挑战。经过多年的技术开发和应用实践,已形成了较为成熟的煤泥分选技术体系,常用的煤泥回收工艺设备包括:压滤机、加压过滤机和沉降离心机。filter press入料适应性强、滤液澄清度高、运行成本低,但产品水分偏高、占地较大;加压过滤机和沉降离心机产品水分低、单机处理能力大、占地较小、自动化程度高,但加压过滤机系统复杂、投资及运行成本较高,沉降离心机回收下限偏高,转子需要定期维修。三种设备各具特点,在国内外均得到了广泛应用,除了单设备回收工艺外,还衍生出“加压过滤+沉降离心”“加压过滤+压滤”“沉降离心+压滤”等联合工艺。只有结合煤泥性质、煤泥量和厂房空间等条件选择合适的煤泥回收设备、工艺才能经济、高效地回收煤泥。另外,工艺布置形式也是煤泥处置的一大难题,尤其对于空间受限的项目,合理利用现有空间布置工艺可为企业节省可观的成本。布尔洞选煤厂是在现有的矿井工业场地新增布置,针对其细煤泥水分高、灰分高、燃点低等特性,以及现有工业场地狭小、无法新增用地的特点,探讨了细煤泥回收工艺选择与布置方法。

1原煤煤质特点及细煤泥特性布尔洞煤矿选煤厂为动力煤选煤厂,是布尔洞煤矿的配套选煤厂,主要入选该矿原煤。布尔洞煤矿位于神东矿区东胜煤田内,生产能力为240万t/a,开采煤层有4层,分别为4-1、4-2上、4-2及6-2号煤层,其中4-1、4-2上和4-2号煤层为大部可采的较稳定煤层,6-2号煤层为全区可采的稳定煤层。此4层煤赋存深度较浅,煤层结构简单,不含或仅含一层夹矸。顶板岩性主要是粉砂岩和砂质泥岩;底板岩性主要是砂质泥岩,局部为细砂岩。该煤矿各煤层有害成分含量低,灰分、硫分含量低,且发热量较高,是良好的民用和动力用煤。布尔洞煤矿的煤质化验资料显示:原煤灰分为35.24%,内水平均为8%,外水约为14%。为了研究原煤的泥化特性和次生煤泥的含量,分别进行了100~13mm原煤的转筒泥化试验和次生煤泥的筛分试验。随着翻转时间的延长,高粒级原煤产率逐渐降低,次生煤泥产率逐渐增高,-0.045mm粒级细泥比重较高且灰分逐渐升高,说明煤质较硬,且易碎,原煤泥化现象较严重。次生煤泥中各粒级灰分随着粒级的减小而逐渐升高,-0.25mm煤泥含量达96.52%,-0.045mm细泥产率84.41%,灰分高达89.56%,严重影响煤泥水沉降,增加煤泥水处理难度。因此在设计中必须充分考虑原煤泥化严重、细泥多的特性,合理选择细煤泥回收工艺和工艺布置。

2细煤泥回收处理工艺选择目前应用较多的动力煤选煤厂细煤泥回收工艺主要有:压滤机单独回收工艺、加压过滤机单独回收工艺、“加压过滤机+压滤机”两段回收工艺[2]、“筛网沉降离心机+压滤机”两段回收工艺。

1) Filter press separate recycling process. Filter press can realise clear water in one press, and it is the ideal gatekeeper for the closed circuit recycling of washing water in coal beneficiation plant. This process is suitable for all power coal processing plants, especially for coal slurry content is small, and the content of fine-grained slurry in the coal slurry is more, it is the ideal process for the fine slurry dewatering and recycling system of the coal processing plant with more serious mud phenomenon.

2) Pressurised filter separate recovery process. Pressurised filter has the advantages of good dewatering effect, large processing capacity, and loose and easy mixing of filtered products. This process is suitable for coal slurry content is larger, less fine sludge content of the coal processing plant, while requiring a higher degree of automation of the washing process, and the use of pressurised filters to do the industrial test is better, or in the same mine to deal with the same type of coal when the effect is more pronounced in the coal processing plant. Pressurised filter feed in general -0.045mm particle content is less than 40%, coal slurry recovery effect is better, for the serious mud, fine-grained material content is higher in the coal plant, because of its high content of fine-grained materials, will lead to pressurised filter capacity is greatly reduced, and even equipment can not operate normally.

3)“加压过滤机+压滤机”两段回收工艺。该工艺采用一段加压过滤机回收+0.045mm粒级的一段底流粗煤泥,二段隔膜压滤机回收-0.045mm粒级的二段底流细煤泥,适用于煤泥一次沉淀较为困难,+0.045mm粒级粗煤泥含量较高,且加压过滤机处理效果良好同时要求水分含量低的选煤厂。4)“筛网沉降离心机+压滤机”单独回收工艺。该工艺采用一段筛网沉降离心机回收+0.045mm粒级的一段底流粗煤泥,二段隔膜压滤机回收-0.045mm粒级的二段底流细煤泥,适用于煤泥一次沉淀较为困难,+0.045mm粒级粗煤泥含量较高,-0.045mm细煤泥含量低于20%,原煤不泥化或泥化现象不严重的选煤厂。由于布尔洞煤矿选煤厂煤质泥化较为严重,煤泥中+0.045mm粒级含量不高,仅为15.59%;且-0.045mm含量很高,达到了84.41%,因此不宜采用加压过滤机和筛网沉降离心机回收,不适合采用两段回收。通过以上分析最终确定本厂细煤泥回收采用压滤机单独回收工艺。

3工艺布置选择压滤机回收系统的工艺布置主要与煤泥产品走向、总平面位置、浓缩车间位置及煤泥晾干场位置等因素有关。主要有以下几种布置形式:

1)压滤回收系统、煤泥晾干场集中一体布置。压滤回收系统单独呈压滤车间布置,并与煤泥晾干场集中一体布置。压滤车间两层布置,二层布置入料搅拌桶和压滤机,一层部分布置入料泵等设备,部分做煤泥落地场地;煤泥晾干场布置在一层。该工艺流程为压滤机拉板卸料的煤泥直接落至一层地面缓冲堆放,通过铲车铲入煤泥晾干场内进行自然晾干后外运。该布置形式适用于工业场地位置受限,主厂房周围场地不足,且没有压滤车间、煤泥晾干场分开布置场地;原煤煤质较差,压滤脱水效果较差,煤泥水分、灰分均偏高,发热量较低,不适宜直接掺入末煤产品中;煤泥含水量太高,不适合胶带转载;煤泥燃点低,不适用进行干燥降水[6];煤泥干燥成本太高,没有经济效益的选煤厂。

2) Filter press recovery system and coal slurry drying yard are arranged separately. The filter press recovery system is arranged separately in the filter press workshop, and the coal slurry drying yard is arranged separately. The filter press workshop is arranged in two layers, the second layer is arranged with feed mixing barrel and filter press, the first layer is partly arranged with feed pump, filtrate pump, coal slurry collecting scraper and transferring belt conveyor, etc. The coal slurry drying yard is arranged according to the closed coal slurry drying yard. The coal slurry drying yard is set up according to the closed coal shed. The process flow is that the coal sludge unloaded from the pulling plate of the filter press falls directly to the collecting scraper on the ground floor, feeds to the transferring belt conveyor, and then is transported to the coal sludge drying yard for unloading and stacking, and then is naturally dried or dried and transported out. This arrangement form is suitable for industrial site location restrictions, insufficient space around the main plant, filter press workshop, coal slurry drying field can not be centrally arranged; raw coal quality is poor, the effect of filter press dewatering is poor, slurry moisture, ash are high, low calorific value, it is not suitable for direct blending into the final coal products; coal slurry drying field needs to be arranged in the drying facilities of the coal preparation plant.

3) Filter press recovery system, main plant and coal slurry drying yard are centrally arranged as a whole. Filter press recovery system and coal sludge drying yard are arranged in one side of the main plant, with two layers, the second layer is arranged with feeding mixing drum and filter press, the first layer is partly arranged with feeding pump and other equipment, and partly as a coal sludge landing site; the coal sludge drying yard is arranged on one layer. The process is that the coal slurry discharged from the filter press pulling plate directly falls to the ground buffer pile on the ground floor, and is shovelled into the coal slurry drying field by shovel to dry naturally and then transported out. This arrangement form is suitable for the industrial site is flat and spacious, convenient for centralised arrangement; the raw coal quality is poor, the effect of filtering and dewatering is poor, the moisture and ash content of coal slurry are high, the heat content is low, it is not suitable for directly mixing into the final coal products; the one-piece arrangement meets the requirements of fire protection partition; the moisture content of coal slurry is too high, it is not suitable for the tape reproduction; the burning point of coal slurry is low, it is not suitable for drying and descaling; the cost of drying coal slurry is too high, it does not have economic benefits. Coal processing plant.

4) The filter press recovery system and the main plant are centrally arranged as a whole, and the coal slurry drying yard is arranged separately. Filter press recovery system is arranged in one side of the main plant, with two layers, the second layer is arranged with feed mixing barrel and filter press, the first layer is arranged with feed pump, filtrate pump, coal slurry collection scraper and transfer belt conveyor. The coal slurry drying yard is set up according to the closed coal shed. The process flow is that the coal slurry unloaded from the pulling plate of the filter press falls directly to the collecting scraper on the ground floor, and then feeds to the transferring belt conveyor, and is transported to the coal slurry drying yard for unloading and stacking, and then is naturally dried or dried in the coal slurry drying yard for external transport. This arrangement form is one of the most commonly used arrangement forms for power coal processing plant. This arrangement form is suitable for the industrial site is flat and spacious, the space location is rich; the raw coal quality is poor, the effect of filtering and dewatering is poor, the moisture and ash content of coal slurry are on the high side, the calorific value is low, it is not suitable to be directly mixed into the final coal products; the coal slurry drying field needs to be arranged with drying facilities of the coal beneficiation plant.

5) Filter press recovery system is arranged separately, and the coal slurry is blended back into the final coal products. Filter press recovery system is arranged separately in the filter press workshop, which is arranged in two layers, the second layer is arranged with feed mixing drum and filter press, and the first layer is arranged with feed pumps, filtrate pumps, coal slurry collection scraper and transfer belt conveyor, etc. The process is that the coal slurry discharged from the pulling plate of the filter press falls directly to the collection scraper, and then feeds to the transfer belt conveyor. The process flow is that the coal slurry discharged from the filter press pulling plate falls directly to the first layer of collection scraper, and then feeds to the reproduction belt conveyor, and is transported to the end of the coal product belt conveyor for blending into the silo. This arrangement form is suitable for industrial site location restrictions, the main plant is not enough space around the main plant, the filter press workshop can not be centrally arranged with the main plant; the raw coal quality is good, the filter press dewatering effect is good, the coal slurry has a high calorific value and is suitable for blending into the final coal products; the integrated arrangement with the main plant can not meet the requirements of the fire protection zoning, and only a separate arrangement can meet the requirements of the fire protection of the coal processing plant.

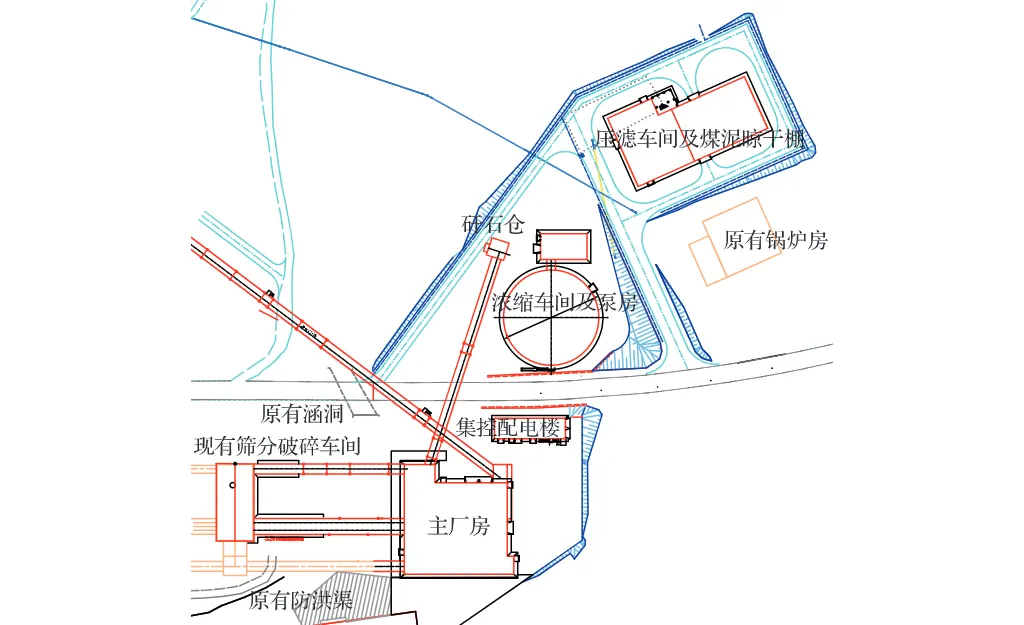

6) Filter press recovery system is centrally arranged with the main plant, and the coal slurry is blended back into the final coal products. Filter press recovery system is arranged in one side of the main plant, with two layers, the second layer is arranged with feed mixing drum and filter press, the first layer is partly arranged with feed pump, filtrate pump, coal slurry collection scraper and reproduction belt conveyor, etc. The process is that the coal slurry unloaded from the pull plate of the filter press falls directly to the collection scraper and reproduction belt conveyor. The process flow is that the coal slurry unloaded from the filter press pulling plate falls directly to the first layer of collection scraper, and then feeds to the reproduction belt conveyor, and is transported to the main plant for blending into the silo on the belt conveyor of the final coal products. This arrangement is also one of the most commonly used arrangement forms in power coal processing plants. This arrangement is suitable for the coal processing plant with flat and spacious industrial site, rich space location; good quality of raw coal, good dewatering effect of filter press, high heat content of coal slurry, which is suitable for blending into the final coal products; and the integrated arrangement with the main plant to meet the requirements of fire protection zoning. By comparing the six process arrangement forms of the filter press recovery system, combined with the general layout of the industrial site of the coal processing plant in Bourdong Coal Mine, as shown in Figure 1.

It can be seen that Bourdong coal processing plant is in the existing mine industrial site new arrangement, the existing industrial site is narrow, the remaining space is small and scattered, can not be newly purchased land, the main plant around the site is not enough, so there is no filter press workshop, coal slurry drying field separate layout site, coal slurry low ignition point is not suitable for drying and precipitation, fine coal slurry in the high-density material kaolin content is more high moisture, combined with the neighbourhood of the actual production of coal plant Combined with the actual production experience of neighbouring coal processing plants, the belt conveyor transport is easy to slip, and the ash content is high, which is not suitable for the coal slurry directly back to mixing the final coal product layout form, so the fine coal slurry recycling system of this coal processing plant is arranged in the form of a centralised integrated arrangement of the filter-pressing and recycling system and the coal slurry drying field.

4 Conclusion

1)The content of fine coal slurry is high in the coal processing plant of Bourdong coal mine, and the raw coal is easy to be sludged, so it is suitable to use the filter press recovery process to recover the fine coal slurry.

2)The fine coal slurry of Boerdong coal mine coal processing plant has the characteristics of high moisture, high ash, low ignition point, etc., the existing industrial site is narrow, the remaining space is small and scattered, and it is not possible to add new land, therefore, the fine coal slurry recycling system of the plant is arranged in the form of filter-pressing and recycling system, and the slurry drying field is centrally arranged in the form of a single unit, which not only can make full use of the existing site space and improve the competitiveness of the final coal products, but also can create good economic benefits for the coal processing plant. economic benefits for the coal processing plant.

Disclaimer: The copyright of this article belongs to the original author and the original source.

Welcome to call us for consultation, technical exchange, and material experiment.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses