In the industrial field, filter press is a widely used equipment for solid-liquid separation, and BMS is a type of filter press.What exactly is a BMS filter press? This article will give you a detailed introduction to the definition, characteristics, applications and development trends of BMS filter press.

I. Definition of BMS Filter Press

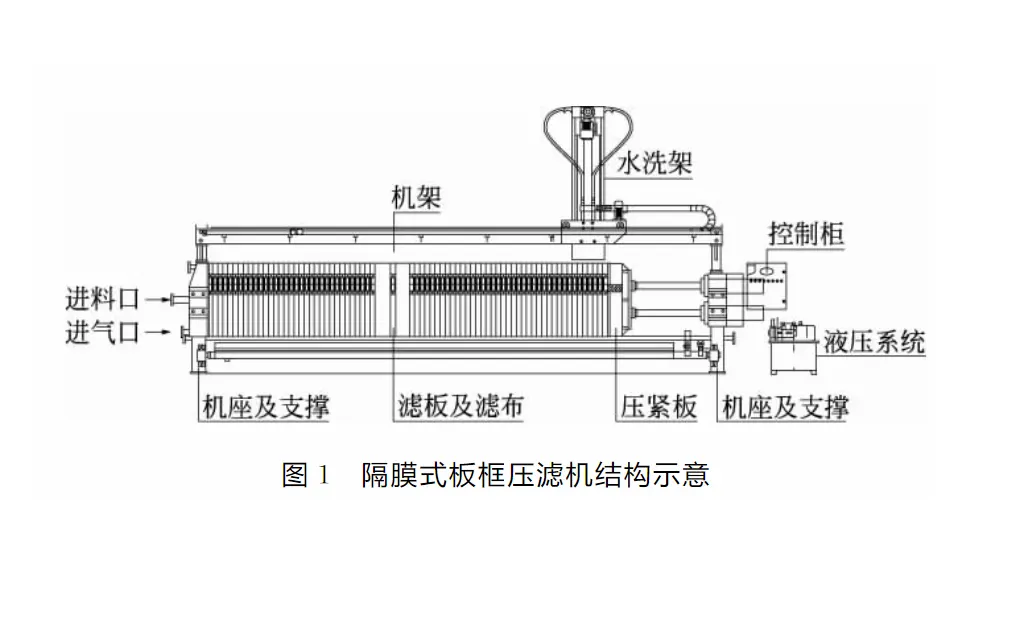

BMS Filter Press, fully known as Plate and Frame Filter Press, is a kind of equipment that uses plates and frames as the filtering medium to realise solid-liquid separation by applying pressure.BMS Filter Press adopts a block of filter plates and frames arranged alternately to form a certain filtration chamber, and the surface of which is covered with filter cloth. When the material enters the filter chamber through the inlet, under pressure, the liquid flows out from the holes on the filter plate through the filter cloth, while the solids are retained in the filter chamber.

II. Characteristics of BMS filter press

1. Good filtration effect: BMS filter press adopts multi-layer filter cloth filtration, which can effectively remove the impurities and particles in the material and achieve high-precision solid-liquid separation.

2. Large processing capacity: BMS filter press has a large filtration area and volume, which is able to process a large amount of materials and improve production efficiency.

3. Wide range of application: BMS filter press is suitable for solid-liquid separation treatment in a variety of industries and materials, such as chemical, pharmaceutical, food, environmental protection and other fields.

4. Simple operation: BMS filter press has a simple structure, is easy to operate, and is easy to maintain and repair.

5. Lower cost: Compared with other filtration equipment, BMS filter presses have lower manufacturing costs, longer service life and higher economic benefits.

III. Application of BMS filter presses

BMS filter presses are widely used in various industries, mainly for solid-liquid separation, mud dewatering, waste residue treatment and other fields. In the chemical industry, BMS filter press can be used for the filtration and separation of catalysts, dyes, pigments and other products; in the pharmaceutical industry, BMS filter press can be used for the filtration and separation of extracts, medicinal liquids, Chinese herbal medicines, etc.; in the food industry, BMS filter press can be used for the clarification and filtration of fruit juices, wines, dairy products, etc.; in environmental protection industry, BMS filter press can be used for the treatment of wastewater, slurry dewatering and so on.

IV. Development trend of BMS filter press

With the continuous development of industrial technology and environmental protection requirements, BMS filter presses are also being improved and perfected. In the future, the BMS filter press will develop in the direction of high efficiency, energy saving, environmental protection and intelligence. Specifically manifested in the following aspects:

1. High efficiency: Improve the filtration efficiency and production capacity of BMS filter presses and reduce energy consumption and material loss by optimising filter media, increasing pressure and increasing filter area.

2. Energy-saving: adopt new energy-saving technologies and materials to reduce the energy consumption and operating costs of the BMS filter press and improve the economic efficiency of the equipment.

3. Environmental protection: Strengthen the environmental protection design and material selection, so that the BMS filter press can reduce pollution and emissions to the environment during operation and meet the increasingly strict environmental protection requirements.

4. Intelligent: Intelligent technology is introduced to realise the automated control and remote monitoring of the BMS filter press, improving the operation convenience and reliability of the equipment.

As an important solid-liquid separation equipment, BMS filter press has a wide range of application prospects and potential development space. With the progress of technology and changes in market demand, BMS filter press will continue to innovate and develop, providing more efficient, environmentally friendly and economical solutions for the production and development of various industries.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses