Diaphragm filter press is a widely used equipment for solid-liquid separation, and one of its core components is the membrane plate. The quality and price of membrane plate has an important impact on the performance and service life of the equipment. In this article, we will provide you with a detailed introduction to the price factors of membrane plate of diaphragm filter press, the market situation and how to choose the right membrane plate.

I. Price Factors of Membrane Filter Press Membrane Plates

The price of membrane plates for diaphragm filter presses varies depending on a number of factors, including the following:

1. Material selection: the quality and performance of membrane sheet materials have an important impact on its price. Common membrane board materials include polypropylene (PP), polyethylene (PE), etc. The performance and price of different materials vary.

2. Processing: The manufacturing process and processing of membrane panels also affects their price. For example, some membrane panels require special treatment or processing, which can increase their manufacturing cost and price.

3. Size: The size of the membrane plate is also an important factor affecting its price. Different sizes of membrane plates are suitable for different filter press models and filtration needs, so the price will be different.

4. Brand and quality: Well-known brands and good quality membrane panels are usually more expensive, but their service life and performance are more guaranteed.

5. Market supply and demand: Supply and demand in the membrane sheet market also affects its price. If market demand exceeds supply, prices may rise; conversely, if supply exceeds demand, prices may fall.

Second, the diaphragm filter press membrane plate market situation

Currently, the market price of membrane plates for diaphragm filter presses varies by region and brand. In some regions, the price of membrane plates is relatively low due to fierce market competition; while in other regions or under specific brands, the price of membrane plates may be higher. Overall, membrane plates with good quality and stable performance are relatively more expensive, but their service life and reliability are also more guaranteed.

Third, how to choose the right diaphragm filter press membrane plate

When choosing membrane plates for diaphragm filter presses, customers are advised to pay attention to the following points:

1. Understanding your needs: Customers should define their filtration needs, such as the type of material to be processed, filtration precision, processing capacity, etc., in order to select the suitable membrane plate.

2. Compare different products: Customers can compare different brands, specifications and types of membrane panels to get information about their performance, price and reputation in order to choose the most suitable product for them.

3. Focus on product quality: customers should choose membrane plates with reliable quality and stable performance, which can ensure the filtration effect and service life of the equipment. Don't just pursue low price and ignore product quality.

4. Consider maintenance: Choosing the right membrane panels can reduce maintenance costs. Customers should be aware of the replacement intervals for membrane panels, how they are replaced, and the maintenance costs required to make an informed decision.

5. Reference to professional advice: Customers can consult professional technicians or manufacturers for professional advice on the performance, precautions for use, and maintenance requirements of membrane panels, so as to better select and use membrane panels.

Membrane plate of diaphragm filter press is one of the important parts of diaphragm filter press, and its quality and price have an important impact on the performance and service life of the equipment. When choosing the right membrane plate for membrane filter press, customers should consider their needs, product quality, market conditions, and post-maintenance. By understanding these factors and making an informed decision, customers can ensure that the membrane plates they choose for their membrane filter press are both economical and reliable, providing a better solution for solid-liquid separation.

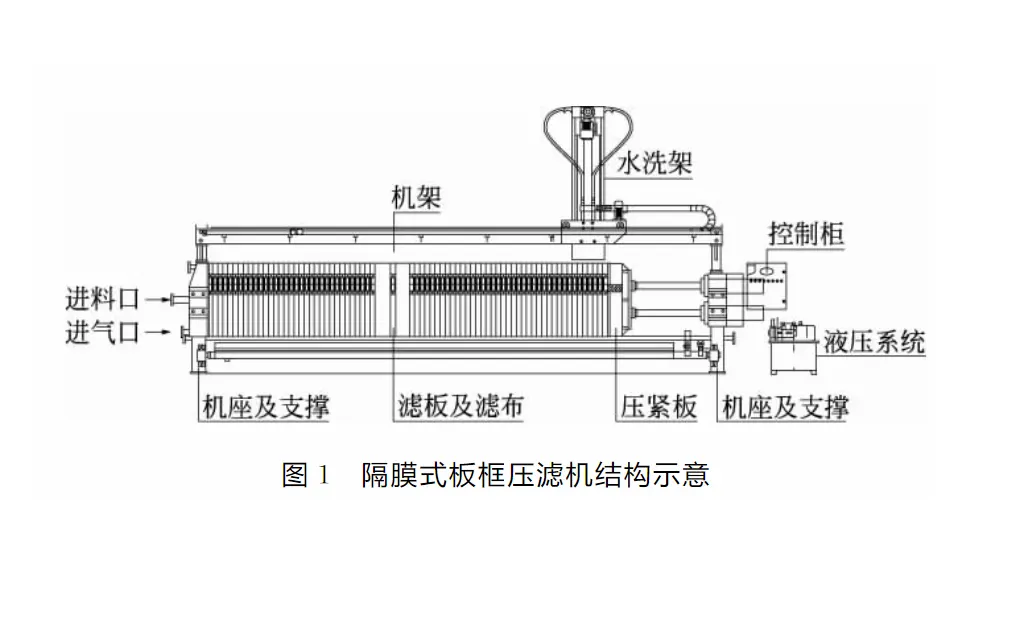

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses