Filter press is a kind of mechanical equipment widely used in industrial production, especially in the fields of sewage treatment, chemical industry, metallurgy and environmental protection. In the factory, filter press is mainly used for solid-liquid separation, i.e., separating the solids in the liquid and solid mixture from the liquid. In this article, we will introduce the use and working principle of filter press in the plant in detail, so that readers can better understand this equipment.

I. Use of filter presses

Filter presses are mainly used in the following areas:

1. Wastewater treatment: In the field of wastewater treatment, filter presses are mainly used for sludge dewatering. The sludge after treatment in the bioreactor and sedimentation tank is piped to the filter press for dewatering. The filter press dewater the sludge by applying pressure so that the water in the sludge is squeezed out. The dewatered sludge cake can be further treated or utilised.

2. Chemical: In the chemical field, filter presses are mainly used for solid-liquid separation. For example, in the production of sulfuric acid, chemical fertiliser and other chemical products, it is necessary to separate the solids in the raw materials from the liquid, and at this time, the filter press can be used for separation.

3. Metallurgy: In the metallurgical field, filter presses are mainly used for solid-liquid separation of mineral slurries. The filter press can separate the useful minerals in the slurry from the solids, such as waste rock, and improve the utilisation of the minerals.

4. Environmental protection: In addition to the above fields, filter presses are also widely used in the field of environmental protection. For example, in the treatment of industrial wastewater, municipal sewage, etc., filter presses can be used for solid-liquid separation, so that the treated water quality meets the emission standards.

Second, the working principle of the filter press

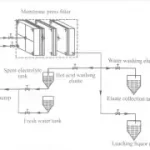

The filter press is mainly composed of feed pump, filter mesh, pressing mechanism and hydraulic system. Its working principle is as follows:

1. The feed pump conveys a mixture of liquids and solids into the filter screen of the filter press.

2. The function of the strainer is to retain the solids on its surface while the liquid flows out through the strainer. At this point, the solids are compressed on the surface of the strainer to form a cake.

3. The pressing mechanism presses the plate frames on both sides of the filter chamber to generate a certain pressure. As time passes, the pressure gradually increases so that the water in the filter cake is squeezed out.

4. The hydraulic system is the power source of the filter press, which pushes the movement of the piston rod and plate frame through hydraulic oil to achieve the functions of filtration and compression.

5. When the preset filtering time or pressure is reached, the filter press automatically unloads and loosens the plate frames on both sides of the filtering screen chamber. Subsequently, the filter cake on the filter screen is scraped down and discharged by the scraper, completing the whole filtration process.

III. Advantages of filter presses

1. High separation efficiency: the filter press adopts high-pressure filtration technology, which can complete the separation of a large number of solid-liquid mixtures in a short time.

2. Energy saving and environmental protection: Compared with traditional separation methods such as sedimentation tanks and centrifuges, filter presses consume less energy during operation and produce less sludge, which is conducive to environmental protection.

3. High degree of automation: most of the modern filter presses adopt intelligent control system, which can realise the functions of automatic feeding, automatic control of pressure and time, etc., which reduces the manual operation and improves the production efficiency.

4. Wide range of applications: due to its features of high efficiency, energy saving and environmental protection, the filter press has a wide range of application prospects in various fields.

As an efficient and energy-saving solid-liquid separation equipment, the filter press is widely used in factories. Its working principle is mainly to make the solids in the liquid and solid mixture be retained on the filter mesh by applying pressure and form the filter cake, while the liquid flows out through the filter mesh. After a period of time, the pressure mechanism is loosened, and the scraper scrapes down and discharges the filter cake, completing the whole filtration process. In the fields of sewage treatment, chemical industry, metallurgy, environmental protection and so on, the filter press plays an important role. With the continuous progress of technology and the increase of application demand, the performance and function of the filter press will be further improved and perfected in the future.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses