Normally, if you want to get an accurate quotation, you are recommended to provide us with this information: 1. The type of sludge to be filtered: is it physical sludge, or biochemical sludge? Conventional filter presses are available for physical sludge, while belt and stacked-screw filter presses are required for biochemical sludge, especially sludge containing oil or viscous sludge.

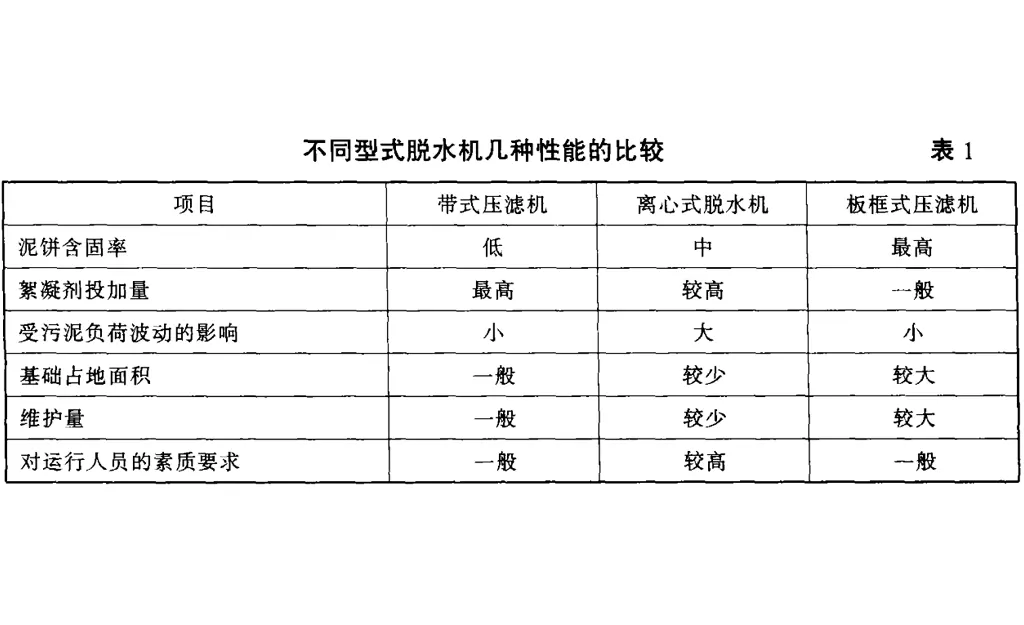

2, the water content of sludge after filtering: chamber filter press, plate and frame filter press, diaphragm filter press after filtering sludge with low water content, stacked-screw filter press after filtering sludge with slightly higher water content, belt filter press with the highest.

3, sludge treatment of continuous or intermittent: chamber filter press, plate and frame filter press, diaphragm filter press filter press can only be used in an intermittent way to deal with sludge, belt filter press and stacked-screw filter press can be a continuous treatment of sludge, high processing efficiency.

4, sludge treatment to meet the floor space requirements: If the customer has a floor space limit, then you can choose vertical filter press, but it will cause the increase of this, if there is no floor space limit, then you can choose other ways.

5, the different forms of filter presses on the feed pump requirements: chamber filter press, plate and frame filter press, diaphragm filter press filtration mode because of the use of intermittent, it is recommended to use diaphragm sludge pumps, while if the belt filter press and stacked screw filter press is recommended to use the sludge screw pumps, you can also use diaphragm sludge pumps.

6, the choice of filter cloth: filter cloth to be selected according to the type of sludge, the regular situation according to our selection book, special circumstances to be selected after a small pilot device test.

7. Site installation conditions (horizontal or vertical installation) and other information.

It's okay if you don't know much about it, our sales managers will assist you in determining that.

Do you have any of your filter presses in stock?

Filter press models and configurations are particularly many, belonging to customised products, we need to select the filter press according to the data you provide to filter the area of the filter, the volume of the chamber, the inlet and outlet of the liquid, the PH value and installation conditions and other working conditions for the selection of filter presses, and to determine the model of the filter press and the configuration of the filter press before delivery to the workshop to place an order for production.

What is your typical lead time?

Depending on the size of the filter press and the specifics of the project, lead times are typically between 30-45 days.

Filter press selection must know:

1. What is the total amount processed in a day (24 hours)?

2. How many hours of work are required in a day (24 hours)?

3. What is the solids content of the sludge sludge at the feed port?

4. The nature of the material (e.g. sludge, calcium carbide sludge, etc.)? Is it organic, biochemical, etc.?

Please contact our sales team for details.

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses