INTRODUCTION

China is the largest coal producer in the world, due to the continuous improvement of coal mining and coal processing mechanisation, the amount of coal slurry and the output of fine-grained coal processing products have increased dramatically, which has brought difficulties in the treatment of coal slurry and coal slurry dewatering and recycling, and resulted in the problem of dewatering of fine-grained products becoming more and more prominent.

Excessive moisture in coal products will not only increase transport costs, but also affect the subsequent use of coal products, such as metallurgy, thermal power generation. In terms of economic benefits, every 1% increase in coal moisture will consume the same amount of profit generated by reducing coal ash content by 4.5%. Effective reduction of fine coal moisture in the development of clean coal technology to provide a breakthrough at the same time, but also for the enterprise to bring intuitive economic benefits. Filter press is a commonly used equipment for dewatering fine coal, and domestic scholars have done a lot of work on the application of filter press.

1.0 Coal Slurry Filter Press Equipment Commonly Used in Coal Processing Plants

Filter press, pressurised filter, centrifugal dewatering machine with sedimentation filter and vacuum pressurised filter are the main equipments for coal sludge dewatering and recycling in coal processing plant, among which filter press, pressurised filter and centrifugal dewatering machine with sedimentation filter are the most commonly used ones. Filter press is the gateway equipment for fine-grained coal slurry dewatering and recycling in coal preparation plant. Filter press equipment can be broadly divided into plate and frame filter press, belt filter press, fast-opening diaphragm filter press and some special new filter press.

1.1 Plate and frame filter presses

Plate and frame filter presses are divided into flat plate and frame filter presses and concave plate and frame filter presses. The main difference between the two is the different structure of the filter chamber. China's current application is more concave plate and frame filter press, usually called chamber filter press.

1.1.1 Structural characteristics and operating principle

Plate and frame filter press mainly consists of body support, filter plate (including dynamic plate, fixed plate, intermediate filter plate), filter plate pressing mechanism, pull open discharge device, feed pump and electrical control system. Factors affecting the effect of filter press filtration mainly include feed pressure, feed nature, feed concentration, filter press chamber thickness, etc. These factors directly affect the filter press cycle time. These factors directly affect the filter press cycle time, product moisture and processing capacity.

Plate and frame filter press has four main stages: feeding slurry, pressurising filtration, discharging cake and washing cloth. Among them, the pressurised filtration to the unloading of the cake accounts for 70%~75% of the whole cycle time, which has the greatest influence on the whole cycle time. Therefore, how to shorten the time period from pressurised filtration to cake unloading is the focus of current research.

1.1.2 Current status of applications

Plate and frame filter press has a wide range of applications, such as the use of its filter press characteristics to deal with the formation of oilfield mining waste, to reduce the environmental pollution caused by its direct discharge potential.

1.2 Fast-opening diaphragm filter presses

On the basis of the traditional filter press, the fast diaphragm filter press, which is improved and designed according to the modern filtration theory, comes into being as a new generation of products.KM type fast diaphragm filter press is the earliest fast-opening diaphragm filter press that is successfully developed and put on the market in China. The fast-opening diaphragm filter press is the replacement of ordinary chamber filter press, and it is the filtration equipment which is very suitable for coal sludge dewatering.

1.2.1 Structural characteristics and operating principle

Fast-opening diaphragm filter press adopts the arrangement form of alternating arrangement of chamber filter plate and diaphragm filter plate (or diaphragm plate and diaphragm plate), multi-port feeding, fast pulling open, automatic discharging, synchronous pressing of multiple cylinders, PLC automatic control and other technologies, which has the features of large processing capacity, fast working cycle and high automation degree. Compared with the traditional chamber filter press, its outstanding feature is the application of diaphragm plate.

A working cycle of fast diaphragm filter press can be divided into five stages: filter plate closing and pressing, preliminary filtration, diaphragm pressing and dewatering, pressurised through-flow dewatering, and grouping and unloading. The diaphragm produces elastic deformation and squeezes the filter cake to carry out the second pressing and dewatering; after pressing and dewatering, the diaphragm pump stops working. High-pressure wind with the help of pressure to replace the water in the pores of the filter cake, then the main hydraulic cylinder continues to pressurise to further reduce the moisture of the filter cake; through the pull-open device to make the filter cake grouped pull-open to unload the filter cake.

1.2.2 Technical comparison with conventional chamber filter presses

Compared with the traditional chamber filter press, the quick-opening diaphragm filter press gets rid of the way of dewatering materials only by feeding pressure. Comparison of the technology of quick-opening diaphragm filter press and chamber filter press. The initial feeding period is the filtration time. When the filtration period is over, the quick-opening diaphragm filter press abandons the traditional method of continuing to press the slurry to reduce the moisture of the filter cake (chamber press time), and stops charging the filter press immediately at the end of the filtration period, shortening the single-cycle time and optimising the filtration efficiency. In order to further dewater the filter cake, the fast-opening diaphragm filter press, on the one hand, adopts the diaphragm press to squeeze the filter cake, destroying the bridge between the particles and extruding the filtrate remaining between the particle voids; on the other hand, the capillary water in the filter cake is removed through the strong airflow through the flow of the replacement, thus lowering the moisture content of the filter cake (diaphragm press time).

After the filtration process, the quick-opening diaphragm filter press squeezes the filter cake again through the diaphragm press, so that the solid content of the filter cake is greatly increased in a short time, which not only shortens the time of filtration, but also improves the solid content of the cake compared with the chamber filter press.

Fast-opening diaphragm filter press has the following advantages due to the improved design of strong high-pressure fluid squeezing dewatering, diaphragm pressing dewatering and cake dewatering by strong airflow through the flow on the basis of the traditional filter press: ① adopting the second diaphragm pressing dewatering process, low moisture of the cake; ② adopting the second diaphragm pressing dewatering process, low moisture of the cake; ③ adopting the second diaphragm pressing dewatering process, low moisture of the cake.

② master and slave multi-cylinder synchronous compression and control technology, shorten the tightening time, improve the tightening force, high pressure, high flow, fast slurry feeding without spraying; ③ multi-port feeding, feeding speed, so that the filter plate force is more reasonable, good cake effect; ④ unique hydraulic drive, circular chain pull open the filter plate group and the filter plate quickly grouped pull open the closing mechanism, the equipment is safe, energy-saving and reliable, to achieve a rapid unloading, to ensure fast and stable compression of the filter plate. Ensure the rapid and stable compression of the filter plate.

1.2.3 Current status of applications

At present, the fast-opening diaphragm filter press has more applications in coal processing plants in China, and the application effect is good in Jining No.3 Coal Mine Coal Processing Plant, Yangquan Coal Group No.2 Coal Processing Plant and Linlux Coal Processing Plant, etc. The KX300/2000 fast-opening diaphragm filter press has been put into use in the coal mine coal processing plant, and the capacity and efficiency of the coal slurry water treatment have been improved, and the filtration cycle time has been shortened to meet the production capacity of the coal processing, and optimise the equipment system configuration, improve the degree of automation and operational stability, and increase the working efficiency. It optimises the equipment system configuration, improves the automation degree and operation stability of the equipment, and improves the working efficiency.

growing trend

Filter press equipment develops in the direction of large-scale, high-efficiency and automation. In order to reduce the number of equipment and floor space is required in the plant supporting a single processing capacity of large-scale filter press equipment, the equipment should have a different coal slurry solid-liquid separation thoroughly, energy saving and high pressure characteristics. Development of new filter media. New filtration media can be divided into a number of small filtration units, and the surface of these filtration units of the cake has a very good shaping effect, the cake shrinkage does not produce cracks, can reduce gas consumption and maintain a stable differential pressure. A continuous filter press with a simplified process flow and without the need for a feed pretreatment system was investigated. The filter press can independently complete the dewatering of materials and has a low failure rate. Improve the intelligent degree of filter press equipment. With the continuous progress of science and technology, the intelligent level of filter press equipment has put forward higher requirements, so that the equipment has the ability to diagnose and solve the faults by itself at the same time, which guarantees the continuity, stability and high efficiency of the production of the equipment.

Welcome to call us for consultation, technical exchange, and material experiment.

Enquiry: 188517-18517

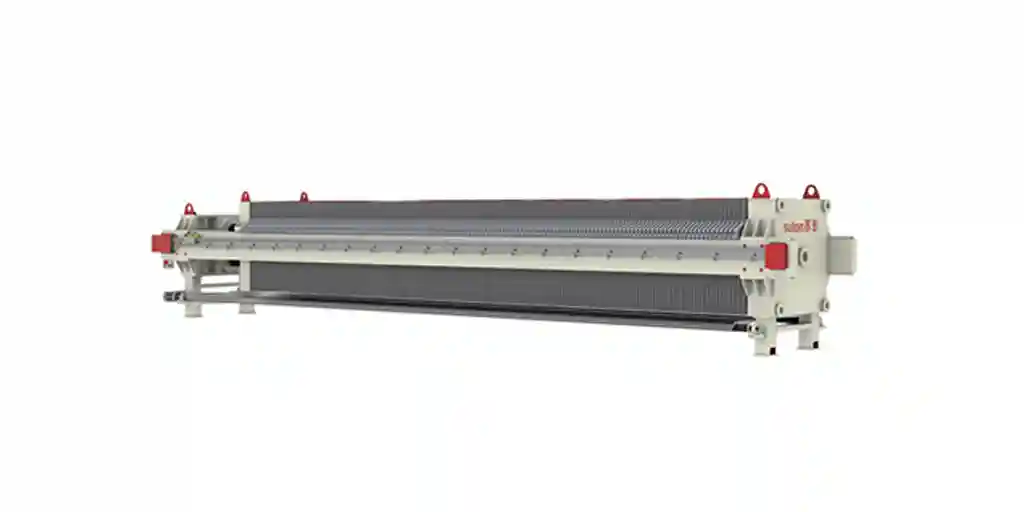

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses