Slurry Filter Press

Polypropylene plate filter pressIncluding plate and frame filter press and chamber filter press two categories, the filter plate selection line enhancement modification, the working filtration pressure can reach 1.2MPa, the temperature resistance of the filter plate can reach 120 ℃ (the temperature resistance of the filter plate can be according to the customer's requirements of special formula design, up to 150 ℃); the use of hydraulic devices as the power to press, loosening of the filter plate, the maximum pressure of the press for the maximum pressure of 25MPa, and can be achieved automatically keep pressure; the use of PLC PLC programme control, easy to operate, safe and reliable. Graphite modified polypropylene composite material filter plate filter press has been recognised as a high-tech product.

Slurry filter press working principle

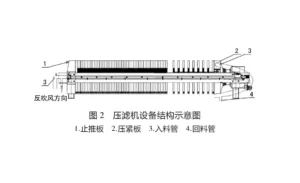

filter pressGenerally consists of head plate, tail plate, filter plate, hydraulic cylinder, main beam, transmission and pull-open device and other parts. The piston of hydraulic cylinder pushes the head plate, so that the filter plate presses the adjacent filter plate to form the filter chamber; the slurry pump sends the slurry into the filter chamber, the water is discharged through the filter cloth through the liquid discharge port, and the solid slurry forms the filter cake in the filter chamber. When the slurry is full of filter chamber, the high pressure pump continues to pressurise the slurry for filtration, so that the solid-liquid is separated in the filter chamber.

1. Pressing the filter plate: Operate the hydraulic system to make the tail plate move towards the head plate, and press all the filter plates between the head plate and the tail plate. As a result, a hollow and sealed filter chamber is formed between the neighbouring filter plates.

2. Filtering process: the feed pump transports the slurry from the feed hole of the tailboard to the filter chamber, and when the chamber is full of slurry, the filtering process starts, and the slurry is separated from the solid-liquid by the pressure of the feed pump.

3. Release the filter plate: Manipulate the hydraulic system to return the head plate to its original position.

4. Filter plate unloadingThe transmission chain on the driving and pulling device pulls the filter plate apart successively, and the filter cake falls off by its own weight and is transported away by the lower conveyor.

At the beginning of filtration, the slurry in the filter chamber cake thickness is not large, the resistance of the cake is small, the dewatering speed is fast, usually this time with a low head, large flow rate of the pump. As the cake thickness increases, the resistance increases, the filtration rate decreases, this time the application of high head and small flow rate of the pump. The time required for the filtration process, according to the slurry filtration characteristics and process requirements and to determine, when the time to reach the required filtration time, stop feeding, filtration process is complete.

aqueousSludge Filter PressThe sludge is transported to the sludge mixing tank through the sludge pump, and coagulant is added for full mixing and reaction, and then flows into the belt-type sludge press, where the sludge is evenly distributed to the gravity dewatering area, and the sludge is moved along with the dewatering filter belt under the action of the mud rake's bi-directional guiding and gravity to quickly remove the free water of the sludge. As the gravity dewatering area is designed to be long, thus achieving a large degree of gravity dewatering. The overturned sludge enters the long wedge-shaped pre-pressure dewatering zone and slowly clamps the unloaded sludge in the gravity zone, forming a sandwich-type interlayer, which is subjected to sequential slow pre-pressure filtration, so as to reduce the residual free water in the sludge layer to a low level.

As the upper and lower two filter belts advance slowly, the upper and lower distance between the two filter belts decreases gradually, and the mud layer in the middle hardens gradually, through the pre-pressure dewatering large-diameter filter rollers, a large amount of free water is removed, and the sludge cake enters the extrusion dewatering area smoothly, and then enters the pressing section, and the sludge is sandwiched in the middle of the upper and lower layers of the filter cloths in the pressing section, and is pressed repeatedly by a number of pressing rollers, and the upper and lower two filter belts pass through the wave-shaped path formed by the interlocking rolls. When the upper and lower filter belts pass through the wave path formed by the staggered rolls, due to the alternating upper and lower positions of the two filter belts, the shear force is generated on the clamped sludge cake, and most of the water remaining in the sludge is pressed and filtered out, which leads to the dewatering of the cake once again, and the dry sludge cake is scraped off through the scraper and transported to the sludge storage place by the belt conveyor or the shaft-less screw conveyor.

Plate and frame filter press industry applications

1、Chemical industry: dyestuffs, pigments, caustic soda, chlorine muted monitor mud, silica, saponin, graphite, bleaching powder, Lide powder, phosphor, insurance powder, chloric acid powder, copper sulphate, manganese sulphate, ferrous sulphate, ferric hydroxide, water purifying agent (aluminium sulphate, polymerized aluminium chloride, alkaline aluminium chloride) and so on.

2. Medical: antibiotics (aureomycin, erythromycin, spiramycin, wellbutrin, madicin, tetracycline, safranin, hygromycin), calcium phytate, traditional Chinese medicines, myo-inositol, growth derivation yarns, organophosphorus, saccharomyces cerevisiae, and so on.

3、Foodstuffs: yellow wine, white wine, fruit juice, beverage, beer, yeast, citric acid, vegetable protein, vegetable molassesin, glucose, maltose, starch sugar, starch, rice flour, corn syrup, gum, carrageenan, monosodium glutamate (MSG), spices, sauce liquid, oral liquid, soya milk and seaweed, anaconda tablets, benadryl tablet and so on.

4、Metallurgy: gold ore, silver ore, copper ore, iron ore, zinc ore, rare earth and other powder beneficiation.

5、Oil refining: white oil, fragrance oil, light oil, glycerin, mechanical oil, vegetable oil, etc.

6, clay: kaolin, bentonite, activated clay, porcelain clay, electronic ceramic clay, etc..

7, sewage treatment: chemical sewage, smelting sewage, electroplating sewage, electrolytic sewage, leather sewage, printing and dyeing sewage, brewing sewage, pharmaceutical sewage, environmental sewage, paper sewage.

8、Coal beneficiation industry, tailing coal treatment, coking coal and so on.

Technical parameters

| FBXY 200-560/1500 400-1200/1800 Main performance/technical parameters: |

| Working filtration pressure | 0.4-0.6MPa |

| Maximum filtration pressure | 22MPa |

| Filter plate acid and alkali resistance | 2<PH<12 |

| Temperature resistance of filter plate | 0-100°C |

| Cake thickness | 32-35mm |

| valid itinerary | 1200mm |

| Diaphragm Pressure | 8-18MPa (subject to no material spray) |

| Area/Filter Plate | filter plate | capacity | power (output) | weights |

| mm | lump (of earth) | m³ | kw | kg |

| FBXY 200/1500 | 51 | 3.8 | 8 | 24300 |

| FBXY 220/1500 | 55 | 4.1 | 8 | 25660 |

| FBXY 250/1500 | 63 | 4.7 | 8 | 28250 |

| FBXY 280/1500 | 71 | 5.3 | 8 | 30920 |

| FBXY 300/1500 | 75 | 5.7 | 8 | 32100 |

| FBXY 320/1500 | 81 | 6 | 8 | 33950 |

| FBXY 340/1500 | 87 | 6.4 | 8 | 35860 |

| FBXY 400/1500 | 101 | 7.6 | 8 | 40400 |

| FBXY450/1500 | 115 | 8.5 | 8 | 45000 |

| FBXY500/1500 | 127 | 9.5 | 8 | 48860 |

| FBXY560/1500 | 143 | 10.6 | 8 | 54100 |

| FBXY 400/1800 | 69 | 7.6 | 8 | 47600 |

| FBXY 450/1800 | 77 | 8.5 | 8 | 51900 |

| FBXY 500/1800 | 87 | 9.5 | 8 | 57000 |

| FBXY 560/1800 | 97 | 10.6 | 8 | 62300 |

| FBXY 600/1800 | 103 | 11.4 | 8 | 64790 |

| FBXY 630/1800 | 109 | 11.9 | 8 | 67400 |

| FBXY 700/1800 | 121 | 13.3 | 8 | 73800 |

| FBXY 750/1800 | 129 | 14 | 8 | 77500 |

| FBXY 800/1800 | 139 | 15.2 | 8 | 82500 |

| FBXY 900/1800 | 157 | 17 | 8 | 93700 |

| FBXY 1000/1800 | 175 | 19 | 8 | 96000 |

| FBXY1100/1800 | 191 | 20.9 | 8 | 105800 |

| FBXY1200/1800 | 209 | 22.8 | 8 | 118600 |

| Remarks: | The final explanation of this product belongs to su-ton and is subject to change without prior notice.

|

| Sales Calls: | TEL:18118100011 |

To learn more about our products, please contact our engineers: 188-517-18-517 for your customised solutions.

Contact Us

Sales:181-181-000-11

Selection:188-517-18-517

Mailbox:suton@su-ton.com

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses