Plate and frame diaphragm filter press

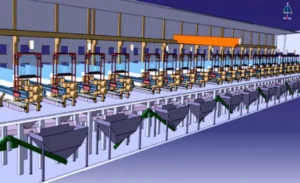

oppressivediaphragm filter press(XAMYZGF) is widely used in the treatment of fine chemicals, food and pharmaceuticals, coating wastewater and other industries, high-pressure diaphragm filter press is a solid-liquid separation equipment integrating machine, electricity and liquid, which mainly consists of frame, filtration, hydraulics, unloading and electrical control and other parts. The bigger feature of diaphragm filter press is that it can carry out secondary drying and pressing of filter cake, the special design of its filter chamber makes it possible to automatically close the feed valve after the filter chamber is filled with filter cake, pass gas or liquid into the filter chamber, make the filter cloth expand and deform, so as to achieve the effect of secondary pressing of the filter cake and further reduce the water.

Our high pressure diaphragmfilter pressProducts of its production process formula is unique, the technical indicators are at the forefront of the domestic level. Continuously gather modern information technology, intelligent, advanced manufacturing technology and new materials, new technology application innovation, can achieve hydraulic, mechanical automation, information technology, intelligent, remote and interface control integration. According to the needs of customers, we can provide customers with manual compression, mechanical compression and hydraulic compression, full-automatic, semi-automatic, PLC programme control, DCS remote control, HMI human-machine interface and other operating modes, as well as open or concealed flow, filtration, washing, pressing, automatic flap collector, automatic sludge storage, filtration pressure of 0.2 ~ 2.0MPa, high temperature and high pressure resistance and other functions of the optional type.

Plate and frame diaphragm filter press working principle

1, the frame is the foundation of the whole set of equipment, it is mainly used to support the filtering mechanism, by the thrust plate, compression plate, seat, cylinder body and the main beam and other connecting components. When the equipment is running, the piston rod on the cylinder body pushes the compression plate, and presses the diaphragm plate, filter plate and filter cloth located between the compression plate and the thrust plate, so as to ensure that the filter slurry with pressure is pressurised and filtered inside the filter chamber.

2. The filtering part consists of diaphragm filter plate, chamber filter plate and filter cloth sandwiched between them, which are neatly arranged on the main beam. At the beginning of filtration, the filter slurry enters into the filter chamber through the inlet of the thrust plate under the push of the feed pump, and the slurry is separated from the solid-liquid with the help of the pressure generated by the feed pump, and the solids stay in the filter chamber to form the filter cake due to the action of the filtering medium (filter cloth) and the filtrate is discharged from the liquid discharge valve.

3, the hydraulic part is the host to complete the pressure and release action of the power unit, under the action of the electrical control system, through the cylinder, oil pump and hydraulic components to complete a series of work in the system: when the system is pressed, the various chambers will be sealed for filtration; conversely, when loosened, for unloading.

4、The unloading mechanism is mainly composed of two gear motors, transmission shaft, sprocket, chain and other components. When the pressure plate is loosened, the motor at the position of the support seat starts, pulling the cylinder seat and pressure plate through the sprocket and chain, and pulling away the filter plate, the motor at the position of the thrust plate starts, driving the spacer to pull away the second part of the filter plate, and then through the signal in the electric control cabinet, the motor reverses, driving the spacer to pull away the rest of the filter plate, in this way, the process of a discharging is completed.

5, the electrical control part is the control centre of the whole system, which is mainly composed of electric control cabinet, circuit breaker, air switch, contactor, intermediate relay, PLC (programmable controller), travel switch, proximity switch and TD200 text display, etc., which can automatically control the whole filter-pressing cycle.

Advantages of plate and frame diaphragm filter press

High Pressure Diaphragm Filter PressAdopting new diaphragm technology, long life, good stability, good versatility, applicable to a variety of industries. Adopting water pressure or pneumatic pressure pressing, the pressure can reach 0.8-2.0mpa. variable filter chamber technology in the chemical, pharmaceutical, mining and other industries solid-liquid separation applications, greatly improve the production efficiency and reduce the water content. High-pressure dewatering technology in the sludge dewatering industry applications, the lower water content of the filter cake to meet the landfill, incineration standards (water content varies in different industries), compared with the traditional dewatering equipment, the weight of the filter cake volume is reduced by half; the whole machine can be fully automated operation, the configuration of the filter cloth online rinsing system and the electronic control valves and instruments, can be achieved unattended.

Plate and frame diaphragm filter press industry applications

1、Chemical industry: dyestuffs, pigments, caustic soda, chlorine muted monitor mud, silica, saponin, graphite, bleaching powder, Lide powder, phosphor, insurance powder, chloric acid powder, copper sulphate, manganese sulphate, ferrous sulphate, ferric hydroxide, water purifying agent (aluminium sulphate, polymerized aluminium chloride, alkaline aluminium chloride) and so on.

2. Pharmaceuticals: antibiotics (aureomycin, erythromycin, spiramycin, wellbutrin, madicin, tetracycline, safranin, hygromycin), calcium phytate, traditional Chinese medicines, myo-inositol, growth derivatives of yarns, organophosphorus, saccharomyces cerevisiae and so on.

3、Foodstuffs: yellow wine, white wine, fruit juice, beverage, beer, yeast, citric acid, vegetable protein, vegetable molassesin, glucose, maltose, starch sugar, starch, rice flour, corn syrup, gum, carrageenan, monosodium glutamate (MSG), spices, sauce liquid, oral liquid, soya milk and seaweed, anaconda tablets, benadryl tablet and so on.

4、Metallurgy: gold ore, silver ore, copper ore, iron ore, zinc ore, rare earth and other powder beneficiation.

5、Oil refining: white oil, fragrance oil, light oil, glycerin, mechanical oil, vegetable oil, etc.

6, clay: kaolin, bentonite, activated clay, porcelain clay, electronic ceramic clay, etc..

7, sewage treatment: chemical sewage, smelting sewage, electroplating sewage, electrolytic sewage, leather sewage, printing and dyeing sewage, brewing sewage, pharmaceutical sewage, environmental sewage, paper sewage.

8、Coal beneficiation industry: coal beneficiation, tailing coal treatment, coking coal and so on.

Technical parameters

| XAMYZG10-500/8001500-U Key performance/technical parameters: |

| Working filtration pressure | 0.6-0.8MPa |

| Maximum filtration pressure | 25MPa |

| Compacting working pressure | 16-20MPa |

| Filter plate acid and alkali resistance | 2<PH<12 |

| Temperature resistance of filter plate | 0-70°C |

| valid itinerary | 400mm/400mm/600mm/8000mm |

| Diaphragm Pressure | 0.8-1.2MPa (press pressure up to 1.6 or 2.0MPa can be designed according to customer requirements) |

| Area/Filter Plate | filter plate | capacity | power (output) | weights |

| mm | lump (of earth) | m³ | kw | kg |

| XAM10/800-U | 5 | 0.15 | 4 | 2400 |

| XAM20/800-U | 9 | 0.3 | 4 | 2750 |

| XAM30/800-U | 14 | 0.45 | 4 | 3100 |

| XAM40/800-U | 19 | 0.6 | 4 | 3500 |

| XAM48/800-U | 23 | 0.72 | 4 | 3800 |

| XAM50/800-U | 24 | 0.75 | 4 | 3900 |

| XAM60/800-U | 29 | 0.9 | 4 | 4250 |

| XAM30/1000-U | 9 | 0.45 | 4 | 4250 |

| XAM40/1000-U | 12 | 0.6 | 4 | 4500 |

| XAM50/1000-U | 15 | 0.75 | 4 | 4800 |

| XAM60/1000-U | 18 | 0.9 | 4 | 5200 |

| XAM70/1000-U | 21 | 1.05 | 4 | 5500 |

| XAM80/1000-U | 24 | 1.2 | 4 | 5800 |

| XAM100/1000-U | 30 | 1.5 | 4 | 6400 |

| XAM110/1000-U | 33 | 1.65 | 4 | 6700 |

| XAM120/1000-U | 36 | 1.8 | 4 | 6900 |

| XAM80/1250-U | 15 | 1.2 | 7.5 | 7300 |

| XAM100/1250-U | 19 | 1.5 | 7.5 | 7800 |

| XAM120/1250-U | 23 | 1.8 | 7.5 | 8300 |

| XAM140/1250-U | 26 | 2.1 | 7.5 | 8700 |

| XAM150/1250-U | 28 | 2.25 | 7.5 | 9100 |

| XAM160/1250-U | 30 | 2.4 | 7.5 | 9500 |

| XAM180/1250-U | 34 | 2.7 | 7.5 | 10300 |

| XAM200/1250-U | 38 | 3 | 7.5 | 11100 |

| XAM220/1250-U | 41 | 3.3 | 7.5 | 11800 |

| XAM200/1500-U | 26 | 3 | 11.5 | 21100 |

| XAM220/1500-U | 29 | 3.3 | 11.5 | 22000 |

| XAM250/1500-U | 32 | 3.75 | 11.5 | 23200 |

| XAM280/1500-U | 36 | 4.2 | 11.5 | 24500 |

| XAM300/1500-U | 38 | 4.5 | 11.5 | 25300 |

| XAM320/1500-U | 41 | 4.8 | 11.5 | 26500 |

| XAM340/1500-U | 44 | 5.1 | 11.5 | 27500 |

| XAM350/1500-U | 45 | 5.3 | 11.5 | 27800 |

| XAM400/1500-U | 51 | 6 | 11.5 | 29500 |

| XAM450/1500-U | 58 | 6.75 | 11.5 | 31200 |

| XAM500/1500-U | 64 | 7.5 | 11.5 | 33200 |

| Remarks: | The final explanation of this product belongs to su-ton and is subject to change without prior notice.

|

| Sales Calls: | TEL:18118100011 |

To learn more about our products, please contact our engineers: 188-517-18-517 for your customised solutions.

Contact Us

Sales:181-181-000-11

Selection:188-517-18-517

Mailbox:suton@su-ton.com

Plate and frame chamber diaphragm filter presses

Plate and frame chamber diaphragm filter presses